High weathering flame-retardant decorative coating and preparation method thereof

A decorative coating, high weather resistance technology, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problem of acid and alkali resistance, water resistance and aging resistance difficult to meet the needs at the same time, flame retardant and high weather resistance coatings preparation cost High, unfavorable general promotion and application, etc., to achieve the effects of excellent mechanical properties, improved flame retardancy, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

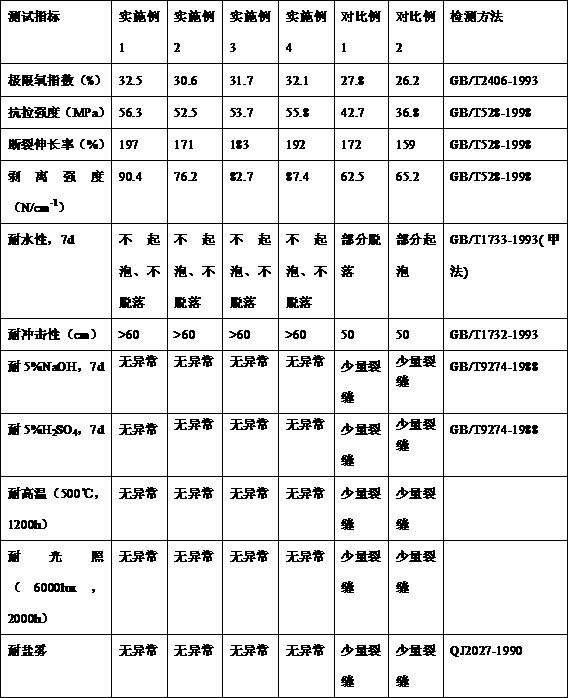

Examples

Embodiment 1

[0017] A high weather-resistant flame-retardant decorative coating, prepared from the following raw materials in parts by weight: 30 parts of hydroxy acrylic resin, 16 parts of carboxyl type vinyl acetate resin, 23 parts of bisphenol A type epoxy resin, 20 parts of glycine, twelve parts of isopropylamine 8 parts of sodium alkylbenzene sulfonate, 10 parts of magnesium hydroxide, 7 parts of antimony trioxide, 10 parts of nano-enhancer, 6 parts of γ-aminopropyl triethoxysilane, tetrabromobisphenol S bis(2, 12 parts of 3-dibromopropyl) ether, 3.5 parts of polyoxyethylene polyoxypropylene ether block copolymer, 2.5 parts of polydimethylsiloxane, 4.5 parts of n-butyl stearate, 5 parts of microcrystalline paraffin, 15 parts of isopropanol, 35 parts of water.

[0018] The nano reinforcement is a mixture of graphene oxide, expanded perlite and titanium dioxide with a mass ratio of 3.5:2:2.5.

[0019] A kind of preparation method of high weather resistance flame retardant decorative pa...

Embodiment 2

[0025] A high weather-resistant flame-retardant decorative coating, prepared from the following raw materials in parts by weight: 20 parts of hydroxyacrylic resin, 12 parts of carboxyl type vinyl acetate resin, 15 parts of bisphenol A type epoxy resin, 10 parts of glycine, twelve parts of isopropylamine 5 parts of sodium alkylbenzene sulfonate, 7 parts of magnesium hydroxide, 4 parts of antimony trioxide, 6 parts of nano-enhancer, 3 parts of γ-aminopropyl triethoxysilane, tetrabromobisphenol S bis(2, 8 parts of 3-dibromopropyl) ether, 2 parts of polyoxyethylene polyoxypropylene ether block copolymer, 1 part of polydimethylsiloxane, 3 parts of n-butyl stearate, 2 parts of microcrystalline paraffin, 10 parts of isopropanol, 20 parts of water.

[0026] The nano reinforcement is a mixture of graphene oxide, expanded perlite and titanium dioxide with a mass ratio of 2:1:1.

[0027] A kind of preparation method of high weather resistance flame retardant decorative paint of the pres...

Embodiment 3

[0033] A high weather-resistant flame-retardant decorative coating, prepared from the following raw materials in parts by weight: 25 parts of hydroxy acrylic resin, 14 parts of carboxyl type vinyl acetate resin, 20 parts of bisphenol A type epoxy resin, 15 parts of glycine, twelve parts of isopropylamine 6 parts of sodium alkylbenzene sulfonate, 8 parts of magnesium hydroxide, 5 parts of antimony trioxide, 8 parts of nano-enhancer, 4 parts of γ-aminopropyl triethoxysilane, tetrabromobisphenol S bis(2, 10 parts of 3-dibromopropyl) ether, 3 parts of polyoxyethylene polyoxypropylene ether block copolymer, 2 parts of polydimethylsiloxane, 4 parts of n-butyl stearate, 5 parts of microcrystalline paraffin, 12 parts of isopropanol, 30 parts of water.

[0034] The nano reinforcement is a mixture of graphene oxide, expanded perlite and titanium dioxide with a mass ratio of 3:1.5:2.

[0035] A kind of preparation method of high weather resistance flame retardant decorative paint of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com