Graphene hybrid particle flame-retardant agent and preparation method and application thereof

A flame retardant, graphene technology, applied in the field of graphene hybrid particle flame retardant, to achieve the effect of easy control and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

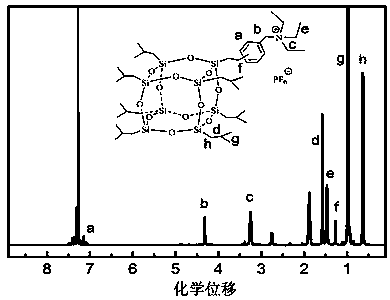

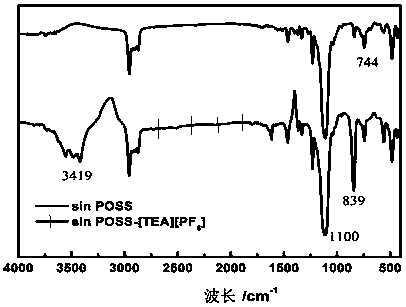

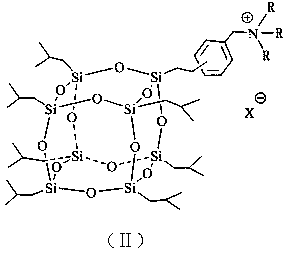

[0035] Take 9.70 grams (0.01mol) of one-armed chlorobenzylethylisobutyl polyhedral oligomeric silsesquioxane (POSS) and dissolve it in 300ml of acetonitrile, then add 2.02 grams (0.02mol) of triethylamine and 0.75 grams of ( 0.005mol) sodium iodide (NaI), stirred and reacted at 80°C for 24 hours, and then added 3.68 grams (0.02mol) potassium hexafluorophosphate (KPF 6 ), stirred and reacted at 20~30°C for 16 hours. After the reaction, the resulting reaction solution was poured into 300ml of water to precipitate a solid product. The resulting mixed solution was suction filtered, washed, and the filter cake was vacuum-dried to obtain 9.34 grams of POSS-based amine salt ionic liquid , abbreviated as POSS-[TEA][PF 6 ], yield 79.1%, the prepared product structure is confirmed, 1 H NMR spectrum see attached figure 1 As shown, the FIIR spectrum of the prepared product is shown in the attached figure 2 shown. Take 4 grams of POSS-[TEA][PF 6 ] and 2 grams of graphene oxide (GO) w...

Embodiment 2

[0039] Take 9.70 g (0.01 mol) of single-arm chlorobenzyl ethyl isobutyl polyhedral oligomeric silsesquioxane (POSS) and dissolve it in 200 ml of acetonitrile, then add 1.18 g (0.02 mol) of trimethylamine and 0.75 g (0.005 mol) sodium iodide (NaI), stirred and reacted at 82°C for 16 hours, and then added 2.20 grams (0.02mol) sodium tetrafluoroborate (NaBF 4 ), stirred and reacted at 20~30°C for 24 hours. After the reaction, the obtained reaction solution was poured into 500ml of water to precipitate a solid product. The obtained mixed solution was suction filtered, washed, and the filter cake was vacuum-dried to obtain 7.80 grams of POSS-based amine salt ions Liquid, abbreviated as POSS-[TMA][BF 4 ], productive rate 72.2%. Take 4 grams of POSS-[TMA][BF 4 ] and 2 grams of graphene oxide (GO) were dissolved in 150ml of propylene carbonate (PC), stirred and reacted at 150°C for 6 hours. After the reaction, the obtained reaction solution was decompressed, distilled, and the filte...

Embodiment 3

[0043] Take 9.70 g (0.01 mol) of one-armed chlorobenzyl ethyl isobutyl polyhedral oligomeric silsesquioxane (POSS) and dissolve it in 500 ml of acetonitrile, then add 2.87 g (0.02 mol) of triethylamine and 0.83 g of ( 0.005mol) potassium iodide (KI), stirred and reacted at 82°C for 20 hours, and added 5.74g (0.02mol) lithium bis(trifluoromethanesulfonyl)imide (LiNTF) to the reaction solution after the reaction 2 ), stirred and reacted at 20~30°C for 20 hours. After the reaction, the resulting reaction solution was poured into 400ml of water to precipitate a solid product. The resulting mixed solution was suction filtered, washed, and the filter cake was vacuum-dried to obtain 7.89 grams of POSS-based amine salt ionic liquid , abbreviated as POSS-[TEA][NTF 2 ], productive rate 60.2%. Take 3 grams of POSS-[TEA][NTF 2 ] and 3 grams of graphene oxide (GO) were dissolved in 200ml of propylene carbonate (PC), stirred and reacted at 150°C for 9 hours. After the reaction, the result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com