Residual glue-free peelable blue glue after peeling and preparation method therefor

A blue glue and residual glue technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of glue breakage, low efficiency, large labor costs, etc., and achieve easy large-scale production, simple preparation process, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

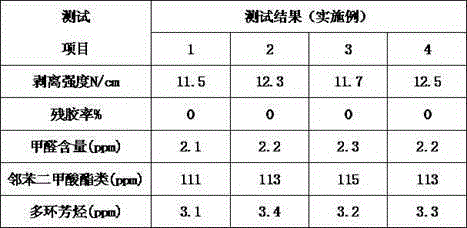

Examples

Embodiment 1

[0028] The peelable blue glue without residual glue after peeling of the present invention comprises the following components in parts by weight: 25 parts of vinyl acetate resin, 30 parts of silicone modified epoxy resin, 8 parts of n-butyl stearate, two 12 parts of silicon oxide, 8 parts of benzoate plasticizer, 9 parts of hydroxyethyl cellulose, 1 part of pigment, 15 parts of nano calcium carbonate, 4 parts of emulsified silicone oil.

[0029] Its preparation process steps are as follows:

[0030] (1) Weigh the materials in the raw material formula by weight fraction;

[0031] (2) Add vinyl chloride resin, silicone modified epoxy resin, and benzoate plasticizer into a reaction kettle with a stirring device, heat up to 50°C, stir at a speed of 200 rpm, and stir for 1 Hour;

[0032] (3) Add hydroxyethyl cellulose, then raise the temperature to the reaction temperature of 70°C, stir at a speed of 300 rpm, and stir for 1 hour; then, add the rest of the raw materials, stir at a...

Embodiment 2

[0034] The peelable blue glue without residual glue after peeling of the present invention comprises the following components in parts by weight: 35 parts of vinyl acetate resin, 20 parts of fluorocarbon modified epoxy resin, 18 parts of n-butyl stearate, two 5 parts of silicon oxide, 2 parts of polyol ester plasticizer, 3 parts of polyvinyl alcohol, 5 parts of pigment, 5 parts of nano talc powder, 10 parts of higher alcohol fatty acid ester compound.

[0035] Its preparation process steps are as follows:

[0036] (1) Weigh the materials in the raw material formula by weight fraction;

[0037] (2) Add vinyl chloride resin, fluorocarbon modified epoxy resin, and polyol ester plasticizer into a reaction kettle with a stirring device, heat up to 70°C, stir at a speed of 400 rpm, and stir for 3 Hour;

[0038] (3) Add polyvinyl alcohol, then heat up to the reaction temperature of 90°C, stir at a speed of 500 rpm, and stir for 2 hours; then, add the rest of the raw materials, stir...

Embodiment 3

[0040] The peelable blue glue with no glue residue after peeling of the present invention comprises the following components in parts by weight: 29 parts of vinyl acetate resin, 25 parts of hydroxyl modified epoxy resin, 13 parts of n-butyl stearate, carbon dioxide 8 parts of silicon, 5 parts of chlorinated hydrocarbon plasticizer, 6 parts of polyacrylate, 3 parts of pigment, 9 parts of nano mica powder, 7 parts of polyoxyethylene polyoxypropylene pentaerythritol ether.

[0041] Its preparation process steps are as follows:

[0042] (1) Weigh the materials in the raw material formula by weight fraction;

[0043] (2) Add vinyl chloride resin, hydroxy-modified epoxy resin, and chlorinated hydrocarbon plasticizer into a reaction kettle with a stirring device, heat up to 60°C, stir at a speed of 300 rpm, and stir for 2 hours ;

[0044] (3) Add polyacrylate, heat up to reaction temperature 80°C, stir at 400 rpm, and stir for 1.5 hours; then, add the rest of the raw materials, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com