Inorganic polymer foaming material prepared from sludge and preparing method of inorganic polymer foaming material

A technology of inorganic polymers and foaming materials, which can be used in applications, household appliances, ceramic products, etc., can solve the problems of waste of resources, increase the cost of manpower and material resources, etc., and achieve the advantages of increasing porosity, good heat storage effect and simple preparation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

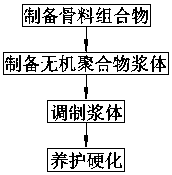

Method used

Image

Examples

Embodiment 1

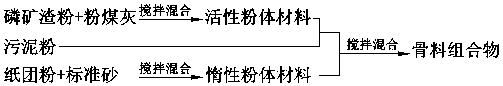

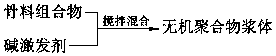

[0041] Such as Figure 1-3 As shown, an inorganic polymer foaming material prepared by using sludge includes an inorganic polymer slurry prepared by mixing an aggregate composition and an alkali activator, and the aggregate composition includes sludge powder and an oxidizing agent. A powder material of aluminum and / or silicon oxide, the sludge powder is prepared by drying sludge. In this embodiment, preferably, the powder material includes a powder material prepared by mixing phosphorus slag powder and fly ash Active powder material, the particle size of the active powder material is less than 3 mm. In the case of a laboratory, it is preferable that the alkali activator is sodium hydroxide.

[0042] An inorganic polymer foaming material prepared from sludge in this embodiment uses sludge produced in sewage treatment as one of the raw materials, which provides a better way for sludge produced in sewage treatment and reduces sludge treatment. The cost of manpower and material reso...

Embodiment 2

[0045] Such as Figure 1-3 As shown, an inorganic polymer foaming material prepared from sludge in this embodiment has the same raw material components as in Example 1, except that the powder material also includes fiber powder and / or standard sand. The particle size of the inert powder material is less than 3mm. In this embodiment, the inert powder material is preferably prepared by mixing standard sand and fiber powder made from waste paper. It is prepared from waste paper through alkalization treatment, drying treatment, and pulverization treatment in sequence. The fiber powder has several powder masses, and the unit volume of the fiber powder includes 5%-30% powder mass. The diameter of the dough floc is less than 5 mm.

[0046] In this embodiment, an inorganic polymer foam material prepared from sludge is used to prepare fiber powder by processing waste paper, which provides a better way for the utilization of domestic waste paper and reduces the manpower and material resou...

Embodiment 3

[0049] Such as Figure 1-3 As shown, an inorganic polymer foaming material prepared from sludge in this embodiment has the same raw material components as in embodiment 2, except that the weight ratio of the raw materials in the inorganic polymer slurry is: sludge Powder: Phosphorus slag powder: Fly ash is 1:1:1; the weight ratio of the sludge powder to the standard sand is 1:(3-10); the weight ratio of the sludge powder to the fiber powder is 1 : (2-3); The weight ratio of the sludge powder to the alkali activator is 1: (0.4-1); it also includes water for reconciling the inorganic polymer slurry, the sludge powder and water The weight ratio is 1: (4.5-5).

[0050] In the raw material formula of an inorganic polymer foaming material prepared from sludge in this embodiment, the amount of each raw material component can be adjusted according to actual conditions to prepare inorganic polymer slurries with different gelation effects, and The weight of the sludge is used as the basi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com