High-strength silane-modified polyether sealant for automobiles and preparation method thereof

A silane-modified polyether, high-strength technology, used in the field of sealants, can solve the problems of poor performance of mechanically modified silane-based structural adhesives, structural differences, and far-flung mechanical properties, etc., to achieve primerless adhesion. effect, high shear strength, improved construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method adopted in embodiment and comparative example comprises the following steps:

[0035] (1) Dry the reinforcing filler and reinforcing carbon black at 100°C for 3 hours, and set aside;

[0036] (2) Add silane-modified polyether resin, reinforcing filler, reinforcing carbon black and 40% water-removing agent in the planetary kettle in sequence, and disperse at high speed for 30-40 minutes;

[0037] (3) Add environment-friendly plasticizer, thixotropic agent, ultraviolet absorber, light stabilizer, antioxidant, first adhesion promoter, second adhesion promoter, adsorbent, 60% by mass of the dewatering agent and the catalyst are mixed uniformly, stirred for 20-40 minutes under the condition of a vacuum degree of -0.09MPa-0.1MPa, and the material is discharged.

[0038] It should be noted that the nano-activated carbon and its composite materials used in the examples of the present invention can be purchased from Shanghai Shuyu Chemical Co., Ltd.

[0...

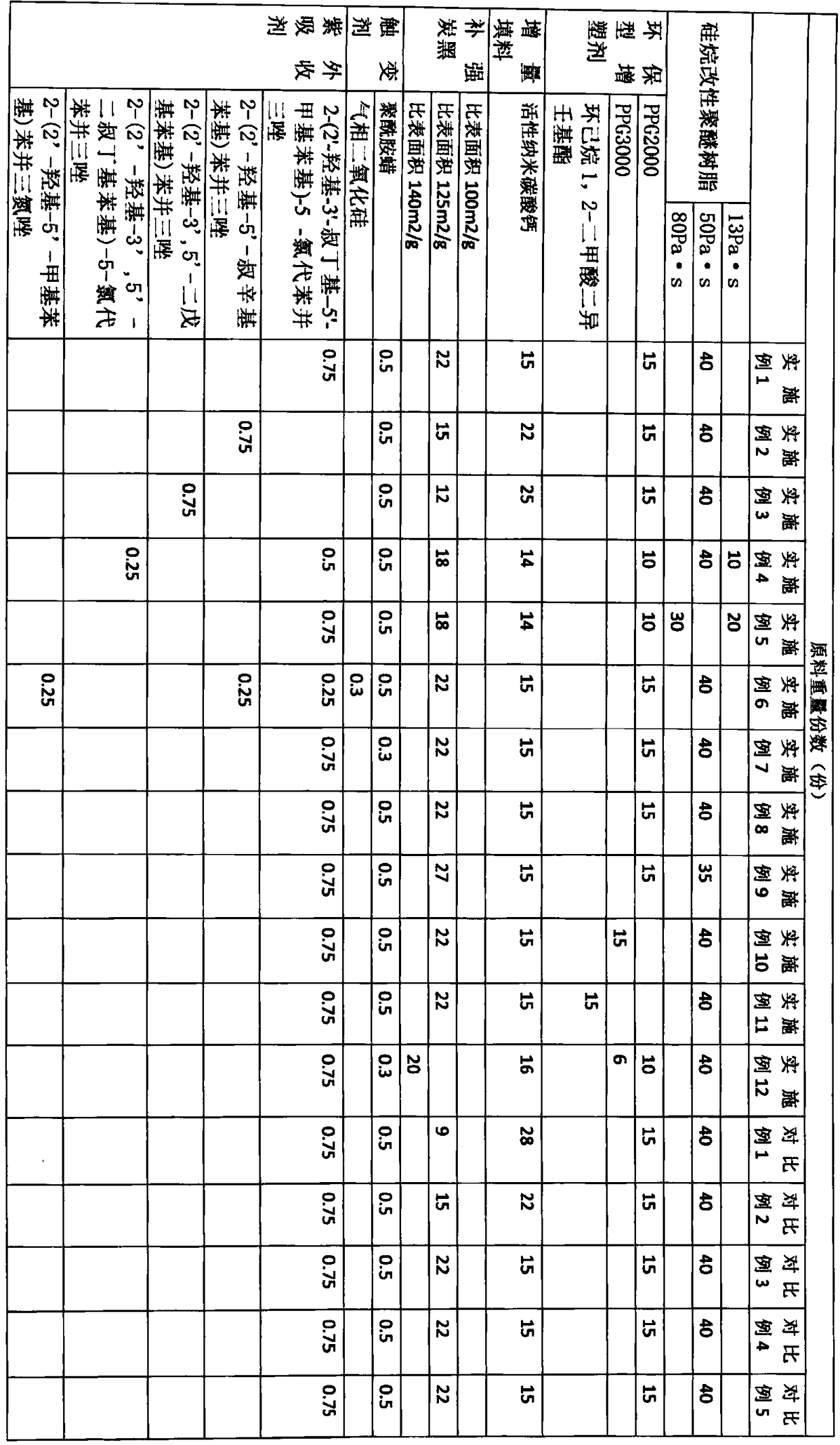

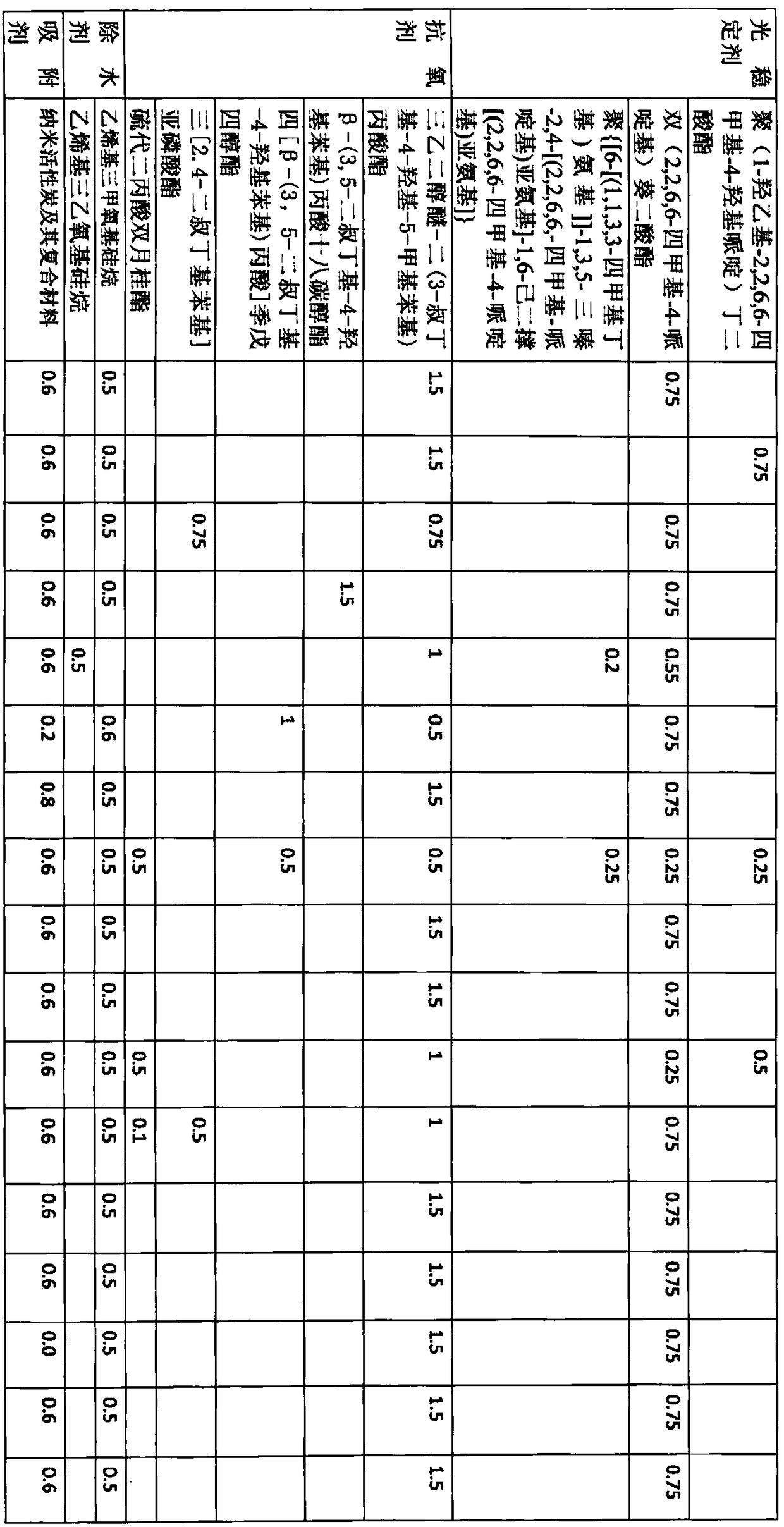

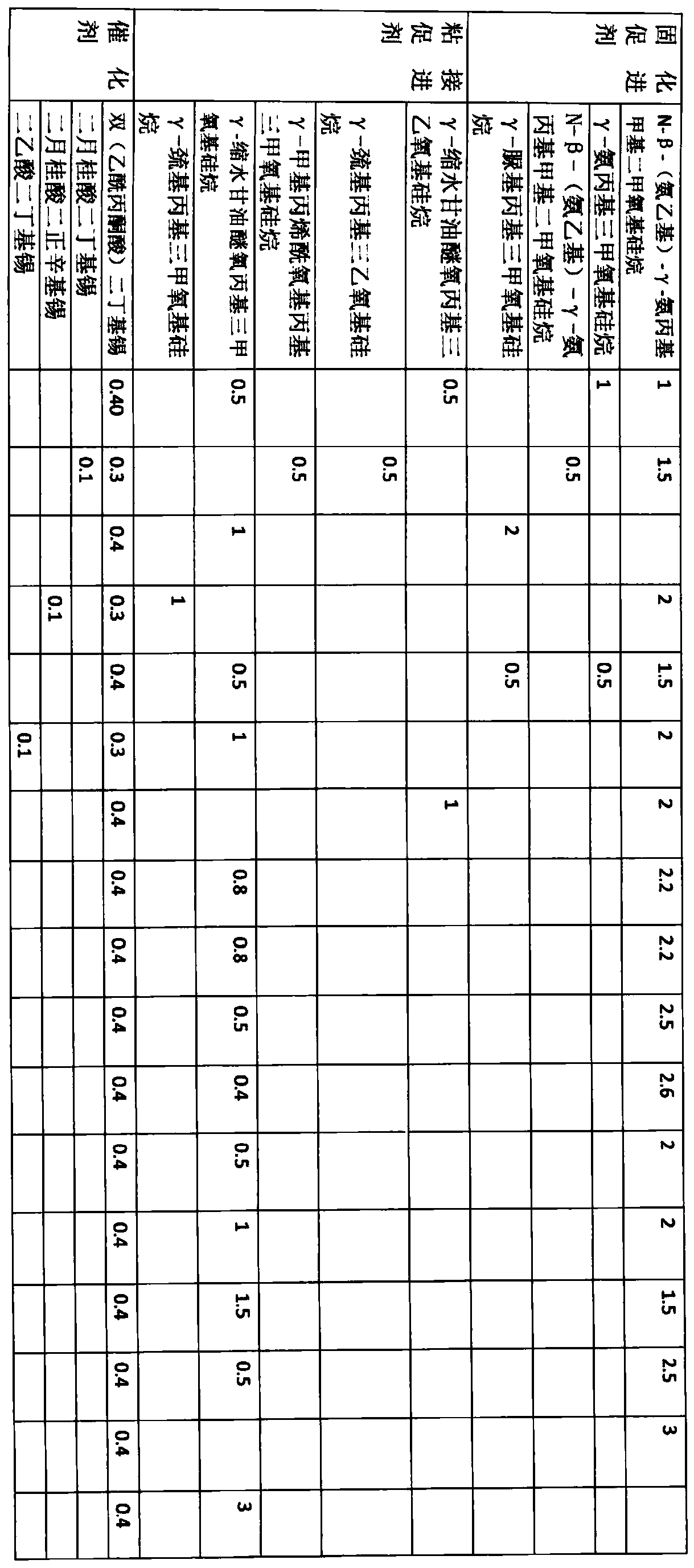

Embodiment 1~12 and comparative example 1~5

[0046] Performance Testing

[0047] Test methods for tensile strength and elongation at break of sealants: refer to GB / T 528-2009 Determination of tensile stress-strain properties of vulcanized rubber or thermoplastic rubber (type II dumbbells);

[0048] Test method for adhesiveness of sealant: refer to GB / T 13477.18-2002 Test Method for Building Sealing Materials Part 18: Determination of Peel Adhesion;

[0049] Test method for shear strength of sealant: refer to GB / T 7124-2008 Determination of tensile shear strength of adhesive (rigid material to rigid material);

[0050] Test method for curing speed of sealant: refer to QC / T 1024-2015 Determination of curing speed in Section 7.7 of one-component polyurethane sealant for automobiles

[0051] Test method of sealant odor level: refer to the determination method of VDA270.

[0052] Table 2 Test results of mechanical properties of silane-modified polyether sealant in each embodiment and comparative example

[0053]

[0054...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com