Building material manufactured by mud as raw material and preparation method thereof

A technology of building materials and raw materials, applied in the field of building materials and their preparation, can solve the problems of lower overall efficiency, the inability of large-scale development and utilization of sludge natural resources, and difficulties in actual use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Specific implementation mode 1: This implementation mode is a kind of building material made of sludge as raw material. The building material is prepared from three raw materials: dry sludge, clay and binder. The addition amount of each raw material is respectively: The clay accounts for 80-150% of the dry sludge mass, and the binder accounts for 5-30% of the dry sludge mass; after mixing the raw materials according to the stated ratio, they are fired at 700-1100°C for 10-30 minutes; Described binding agent is water glass; Its preparation method comprises the following steps successively:

[0006] a. Dry, crush and screen the sludge;

[0007] b. Add clay accounting for 80-150% of the dry sludge mass and water glass accounting for 5-30% of the dry sludge mass as a binder, mix it with the dry sludge evenly, inject it into the mold, and vibrate and extrude;

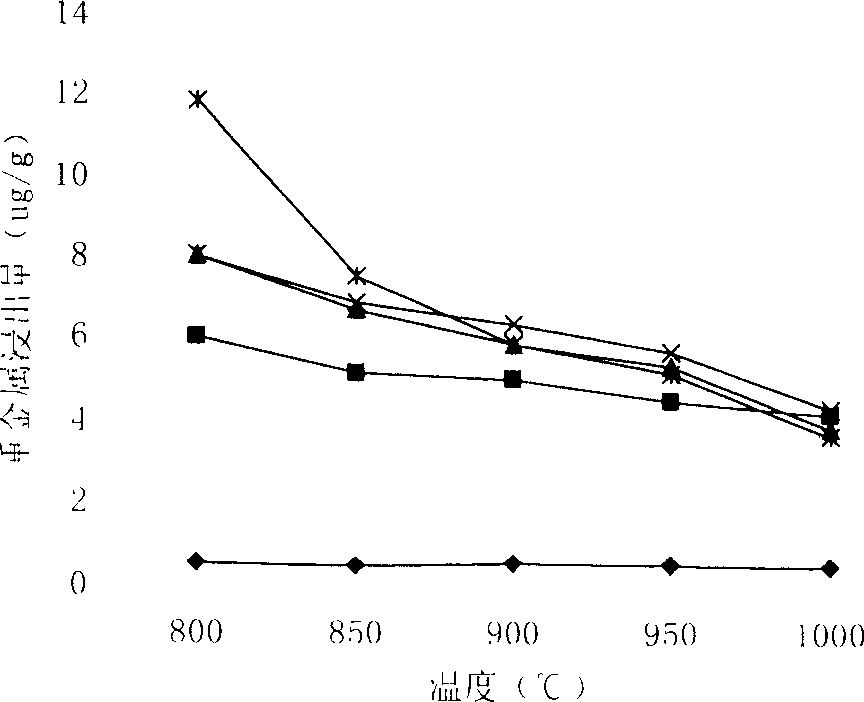

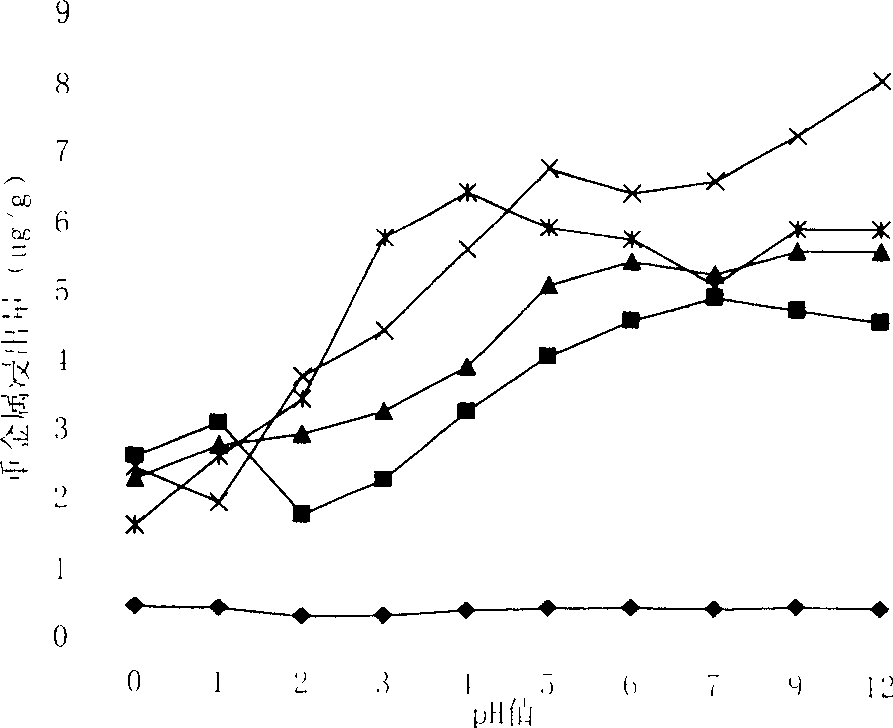

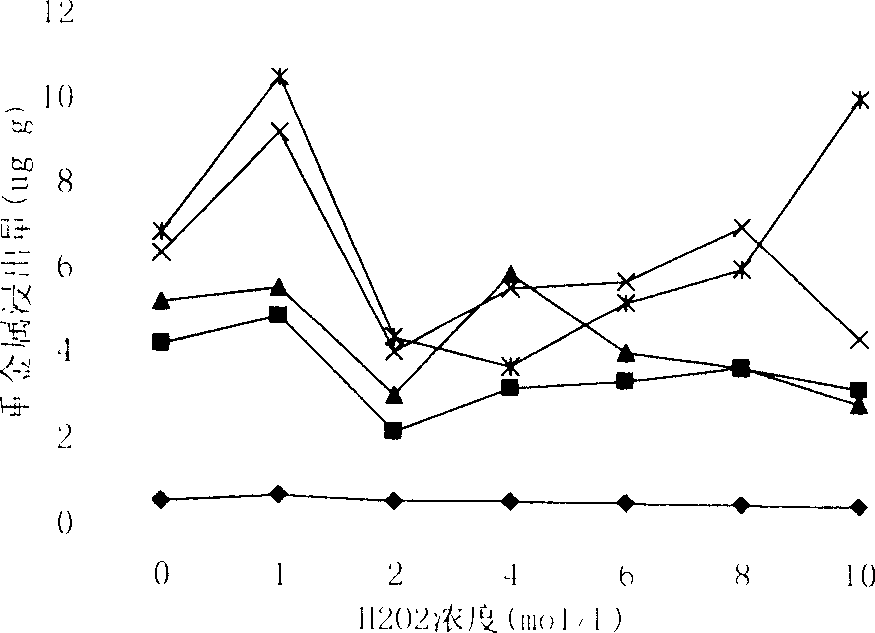

[0008] c. Sintering: first dry and preheat the molding material to fully remove the moisture; then bake at 700-110...

specific Embodiment approach 2

[0010] Specific embodiment two: This embodiment is a kind of building material made of sludge as raw material. The building material is prepared from three kinds of raw materials: dry sludge, clay and binder. The addition amount of each raw material is respectively: The clay accounts for 300-400% of the mass of the dry sludge, and the binder accounts for 10-20% of the mass of the clay; after mixing the raw materials according to the stated proportions, they are fired at 900-1200°C for 15-35 minutes, and the adhesive Binder is water glass; Its preparation method comprises the following steps successively:

[0011] a. Dry, crush and screen the sludge;

[0012] b. Add clay accounting for 300-400% of the mass of the dry sludge and water glass accounting for 10-20% of the mass of the clay as a binder, mix it evenly with the dry sludge, inject it into the mold, and vibrate and extrude;

[0013] c. Sintering: first dry and preheat the molding material to fully remove the moisture; t...

specific Embodiment approach 3

[0015] Specific embodiment three: In the building materials of this embodiment, the addition amount of each raw material is respectively: clay accounts for 100% of the mass of dry sludge, and binder accounts for 10% of the mass of dry sludge; each raw material is mixed according to the stated ratio Finally, it was fired at 900°C for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com