High-strength high-elasticity niobium-containing copper alloy and preparation method thereof

A copper alloy and high-elastic technology, applied in metal rolling, temperature control, elongation control, etc., can solve the problems of beryllium element's strong volatility, strong carcinogenicity, and easy oxidation, so as to reduce uneven composition and super The effect of high strength and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, a high-strength and high-elastic niobium-containing copper alloy is composed of the following components by weight percentage: Ni 22%, Mn 22%, Al 1.2%, Nb 0.3%, Cr 0.3%, Zr 0.1%, and the balance is Cu, The sum of the mass percentages of each component is 100%.

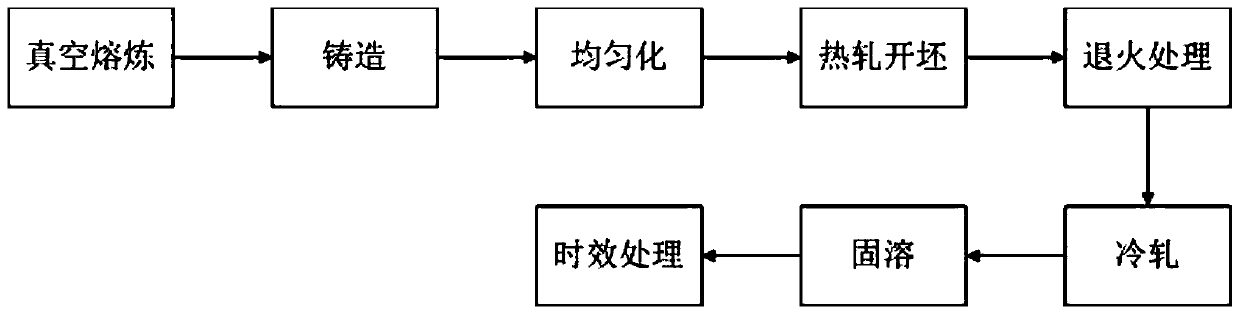

[0035] The preparation method of the above-mentioned high-strength and high-elastic niobium-containing copper alloy, such as figure 1 shown, including the following steps:

[0036] (1) Vacuum melting: batching is carried out according to the components of the copper alloy, and the alloy is melted in a vacuum melting furnace at a melting temperature of 1250-1350°C to obtain a copper alloy solution;

[0037] (2) Casting: cast the copper alloy solution at 1100-1200°C, and obtain alloy ingots after cooling;

[0038] (3) Homogenization: the ingot is subjected to homogenization treatment, the homogenization temperature is 920° C., and the time is 8 hours to obtain a homogenized ingot;

[0039] (...

Embodiment 2

[0048]In this embodiment, a high-strength and high-elastic niobium-containing copper alloy is composed of the following components by weight percentage: Ni 18%, Mn 18%, Al 2.0%, Nb 0.5%, Cr 0.5%, Zr 0.2%, and the balance is Cu, The sum of the mass percentages of each component is 100%, and its preparation method is the same as in Example 1.

Embodiment 3

[0050] In this embodiment, a high-strength and high-elastic niobium-containing copper alloy is composed of the following components by weight percentage: Ni 22%, Mn 22%, Al 0.5%, Nb 0.2%, Cr 0.2%, Zr 0.05%, and the balance is Cu, The sum of the mass percentages of each component is 100%, and its preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com