High-strength high-elasticity copper-nickel-manganese alloy and preparing method thereof

A high-elasticity, copper-nickel-manganese technology, which is applied in the field of high-strength and high-elasticity copper-nickel-manganese alloy and its preparation, can solve the problems of reduced strength and elasticity of beryllium bronze, unable to meet high-temperature service conditions, endangering health and other problems, and achieves improved plasticity. , Ultra-high strength, reducing the effect of uneven composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, a high-strength and high-elastic copper-nickel-manganese alloy is composed of the following components by weight percentage: Ni20%, Mn20%, Nb0.3%, Cr0.3%, Zr0.1%, and the balance is Cu, each The sum of the mass percentages of the ingredients is 100%.

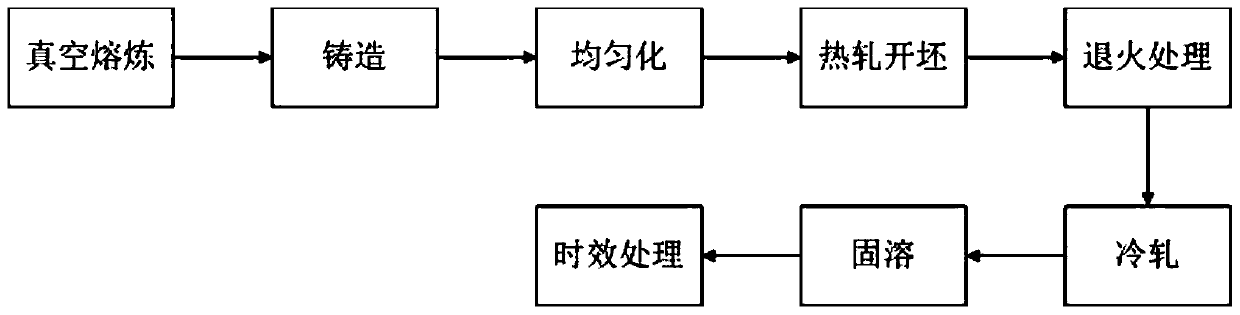

[0034] The preparation method of above-mentioned high-strength high-elasticity copper-nickel-manganese alloy, such as figure 1 shown, including the following steps:

[0035] (1) Vacuum melting: batching is carried out according to the components of the copper-nickel-manganese alloy, and the alloy is melted in a vacuum melting furnace at a melting temperature of 1250-1350°C to obtain an alloy solution;

[0036] (2) Casting: cast the alloy solution at 1100-1200°C, and obtain alloy ingots after cooling;

[0037] (3) Homogenization: the ingot is subjected to homogenization treatment, the homogenization temperature is 920° C., and the time is 8 hours to obtain a homogenized ingot;

[0038] (4) Hot-rolled...

Embodiment 2

[0047] In this embodiment, a high-strength and high-elastic copper-nickel-manganese alloy is composed of the following components by weight percentage: Ni18%, Mn18%, Nb0.5%, Cr0.5%, Zr0.2%, and the balance is Cu, each The sum of the mass percentages of the ingredients is 100%, and its preparation method is the same as in Example 1.

Embodiment 3

[0049] In this embodiment, a high-strength and high-elastic copper-nickel-manganese alloy is composed of the following components by weight percentage: Ni22%, Mn22%, Nb0.2%, Cr0.2%, Zr0.05%, and the balance is Cu, each The sum of the mass percentages of the ingredients is 100%, and its preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com