A kind of sugar boiling tank with waste heat recycling

A technology of boiling sugar tanks and waste heat, which is applied in the fields of application, sugar crystallization, and sucrose production. It can solve problems such as energy waste and achieve the effect of reasonable location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

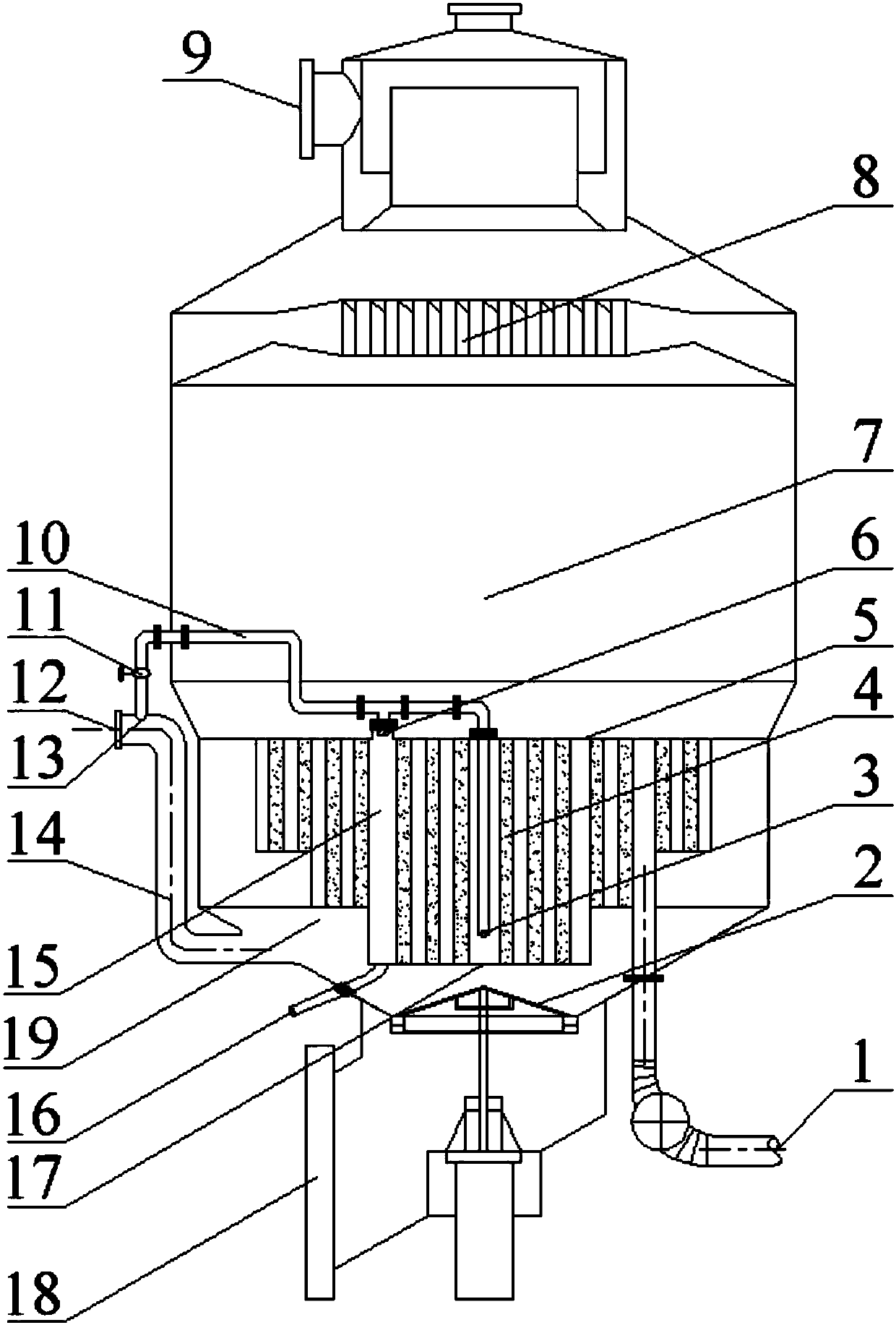

[0020] A sugar cooking tank for waste heat recycling, comprising a tank bottom 19, a steam chamber 7 and a steam drum 15, the tank bottom 19 is provided with a feed pipe 14 and a massecuite outlet 18, and the steam chamber 7 is provided with a juice catcher 8 and The juice steam outlet 9, the steam drum 15 are provided with a condensed water removal pipe 16, a heating steam inlet pipe 1 and a non-condensable gas removal pipe 10, and the outlet 13 of the non-condensable gas removal pipe is connected to the feed pipe 14. The non-condensable gas removal pipe 10 is provided with a valve 11 . When the valve 11 was opened, the non-condensable gas in the steam drum 15 was sprayed into the feed pipe 14 through the non-condensable gas removal pipe 10, and then entered into the steam chamber 7 through the feed pipe 14, and finally mixed with the two gases produced by the sugar boiling process. Secondary steam is sucked away by condenser or vacuum pump through juice catcher 8 and juice v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com