Sand box turnover device for butterfly valve casting

A flipping device and sand box technology, applied in casting equipment, mold handling equipment, manufacturing tools, etc., can solve the problems of casting falling off, difficult operation, personal injury, etc., to achieve smooth flipping process, ensure integrity, and reduce bumps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

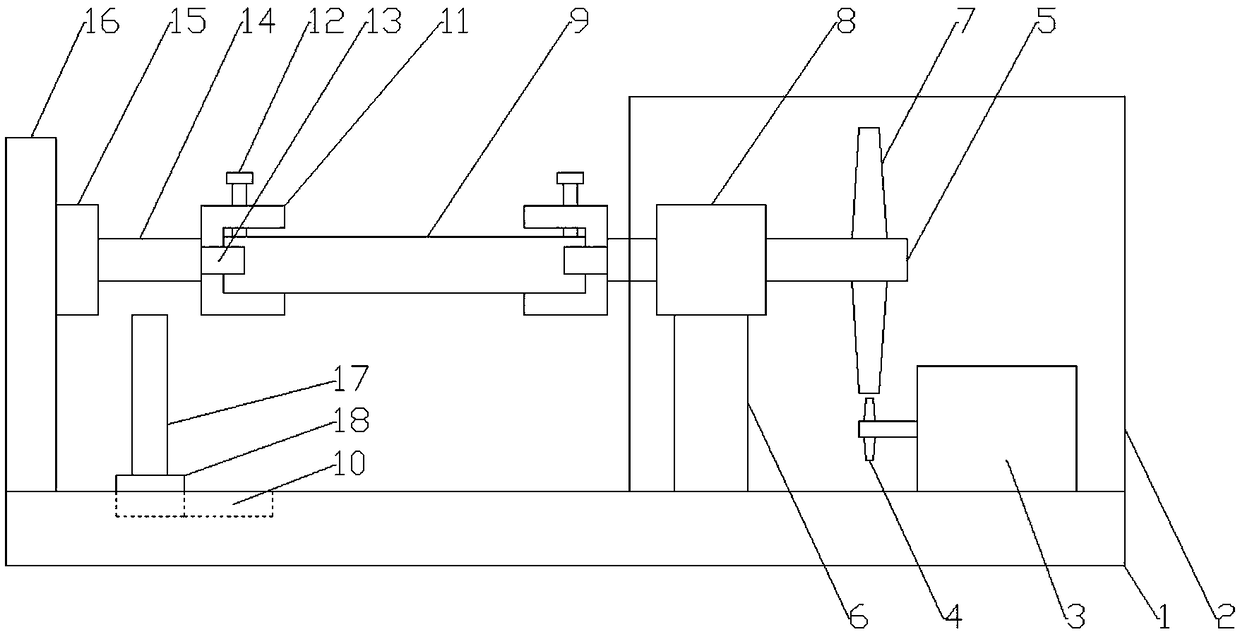

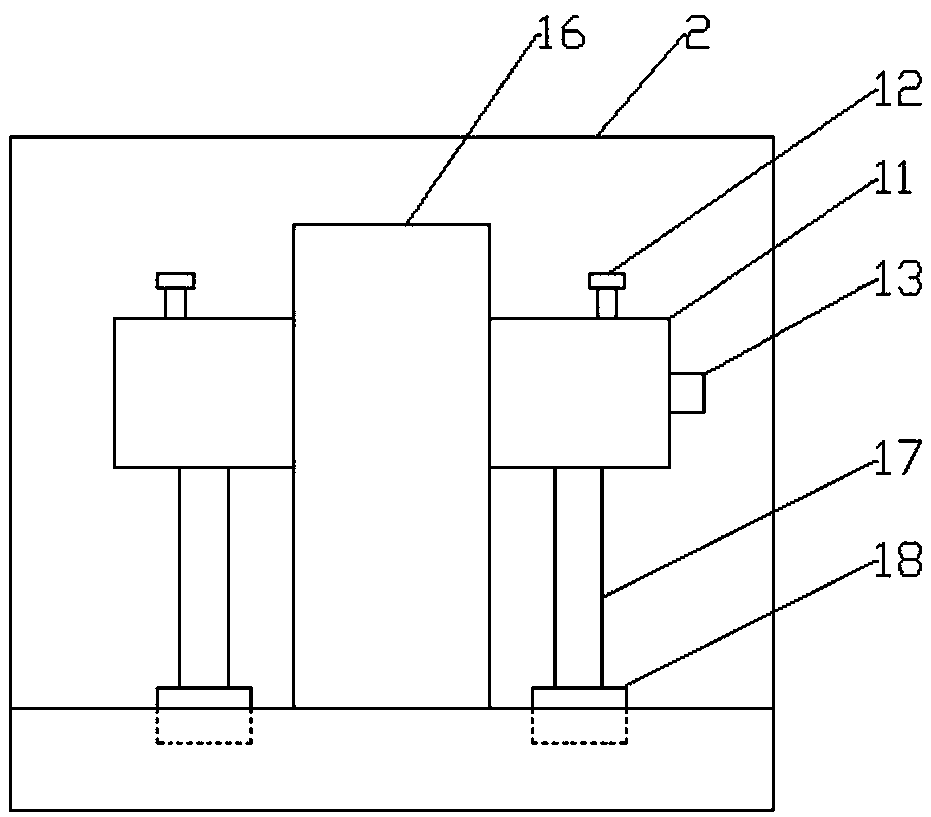

[0013] Figure 1-2 Show the specific embodiment of the present invention: a kind of sand box 9 turnover device that butterfly valve casting is used, comprises base plate, and described base plate two ends are provided with support plate 16 and pillar 6, and described support plate 16 side is provided with rotating seat 2 15, The second rotating seat 15 is provided with a rotating rod two 14, and two slide grooves 10 along the length direction of the base plate are arranged below the rotating rod two 14, and a slide block 18 is provided in the slide groove 10, and the slide block 18 upper ends are fixed with support column 17, described pillar 6 upper ends are provided with rotating seat one 8, are provided with rotating rod one 5 in described rotating seat one 8, the front ends of described rotating rod one 5 and rotating rod two 14 are all provided with C-shaped clamping head 11, sand box 9 is arranged between described clamping head 11, and the upper end of described clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com