Turnover avoiding mechanism for rubber plates of sucking disk of dust collection vehicle

A vacuum cleaner and rubber technology, applied in construction, cleaning methods, road surface cleaning, etc., can solve the problems of easy wear of the rubber plate, unfavorable low-cost use, and reduced dust absorption effect of the suction chamber, so as to facilitate cleaning and use Convenience, wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

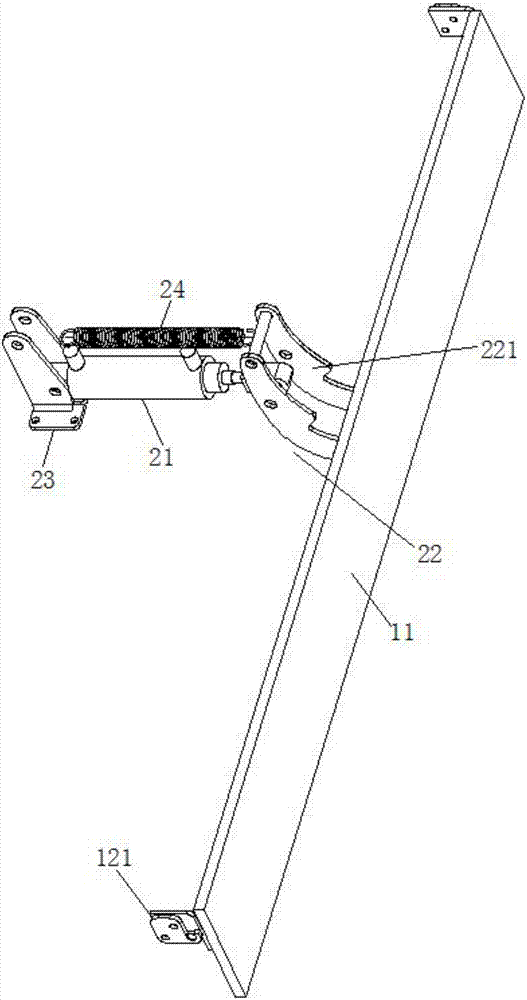

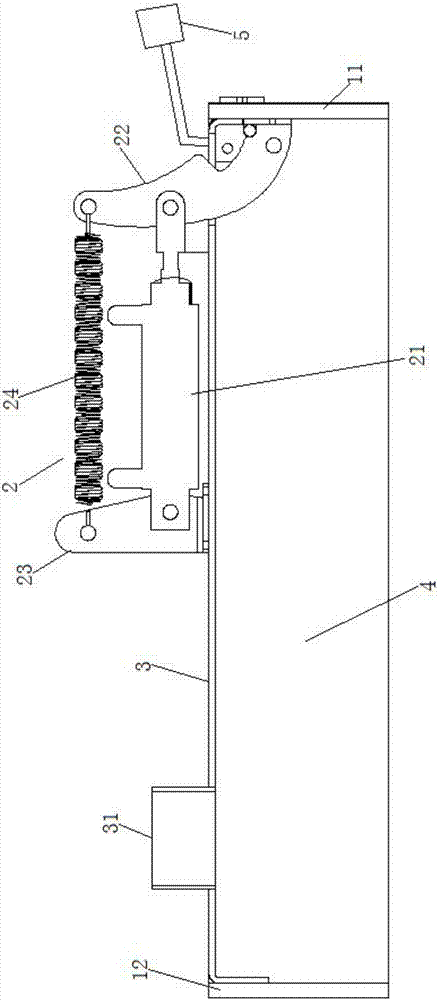

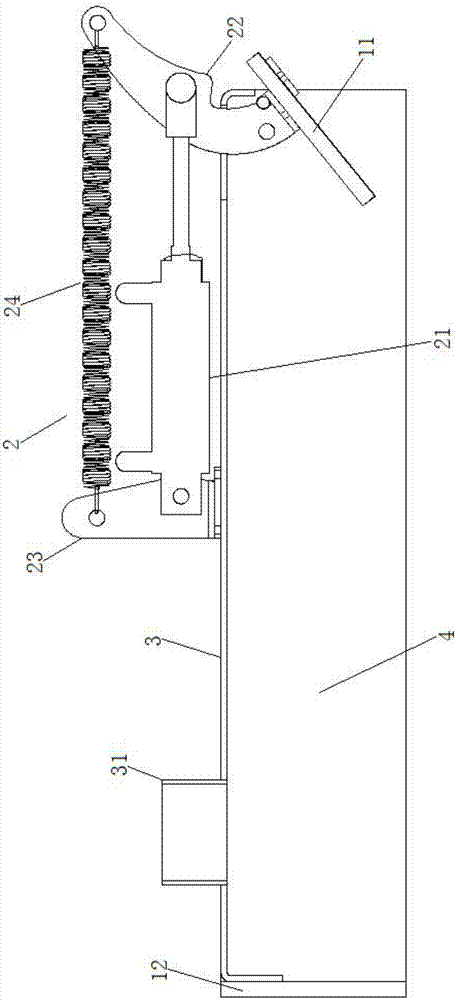

[0031] Example: such as Figures 1 to 3 As shown, the suction cup rubber plate flipping avoidance mechanism of the vacuum vehicle suction cup in this embodiment includes a rubber plate and at least one flipping drive mechanism 2;

[0032] The above-mentioned rubber sheet includes a first rubber sheet 11 and a second rubber sheet 12, the above-mentioned first rubber sheet 11 is rotatably arranged on the front side of the suction cup 3, and the above-mentioned second rubber sheet 12 is surrounded by the rear side and both sides of the suction cup 3, the above-mentioned The lower ends of the first rubber plate 11 and the second rubber plate 12 are located below the suction cup 3 and are flush with each other;

[0033] A suction chamber 4 with an open lower end is formed between the first rubber plate 11, the second rubber plate 12 and the suction cup 3;

[0034] At least one turning drive mechanism 2 is installed on the front side of the upper end of the suction cup 3, and its d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com