Linear feeding mechanism of double-face-chamfering continuous machining system for automobile synchronizer gear sleeve

A linear feeding and processing system technology, applied in the direction of gear cutting machines, metal processing, components with teeth, etc., can solve the problems of complicated mechanism, large processing area, low production efficiency, etc., to improve production efficiency, reasonable design, flip flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Combine below Attached picture The present invention is described in further detail through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

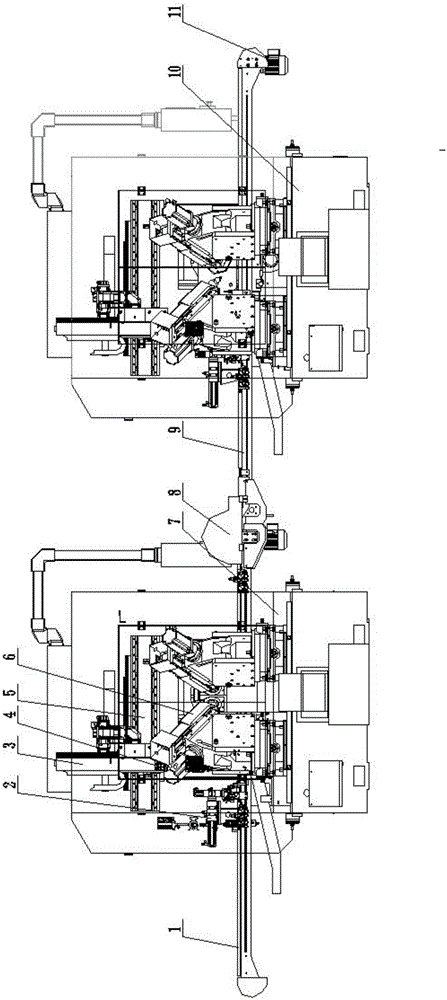

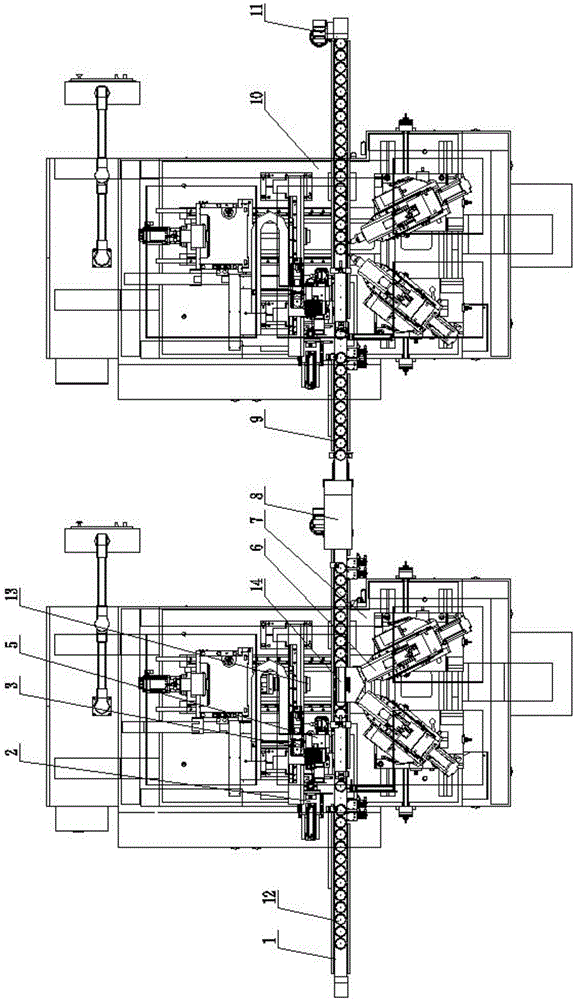

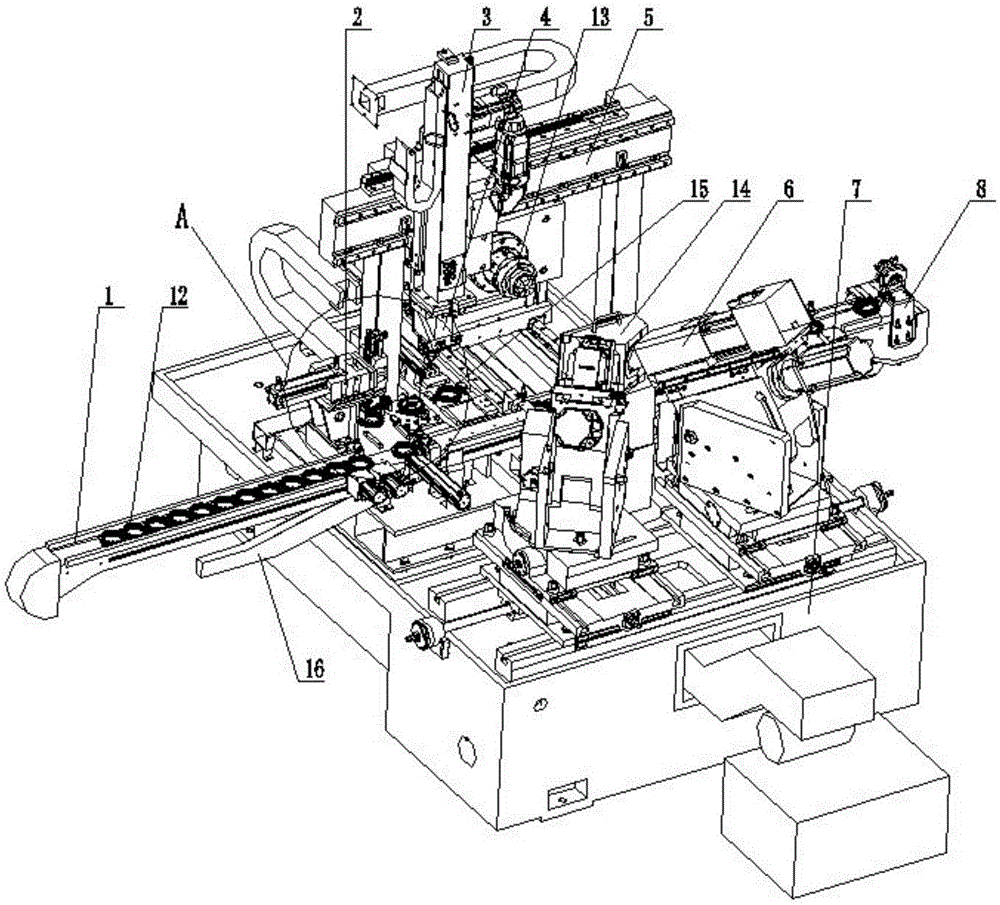

[0028] A linear feeding mechanism for a continuous processing system for double-sided chamfering of gear sleeves of automobile synchronizers. For the structure of the processing system involved, see figure 1 、 2 , 3, 4 are made of two identical double-knife chamfering machines 7,10 and a linear feeding mechanism 1,9 that traverses the two chamfering machining stations. Two identical double-knife chamfering machines are arranged side by side in a row, and each chamfering machine includes a cutter 6 for chamfering, a workpiece driving head 13 and a gear alignment mechanism 2, and the cutters are two in parallel, two The common outer cover of the cutting tool is a dust removal cover 14, and the center line where the two cutting tools ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com