Self-locking type box overturning machine

A self-locking, box-turning machine technology, applied in the direction of conveyor objects, emptying containers, loading/unloading, etc., can solve the high cost of use and maintenance of four cylinders, poor synchronization of four cylinders, and cannot be guaranteed Clamping force and other issues, to achieve the effect of flexible turning, simple structure, stable and consistent clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

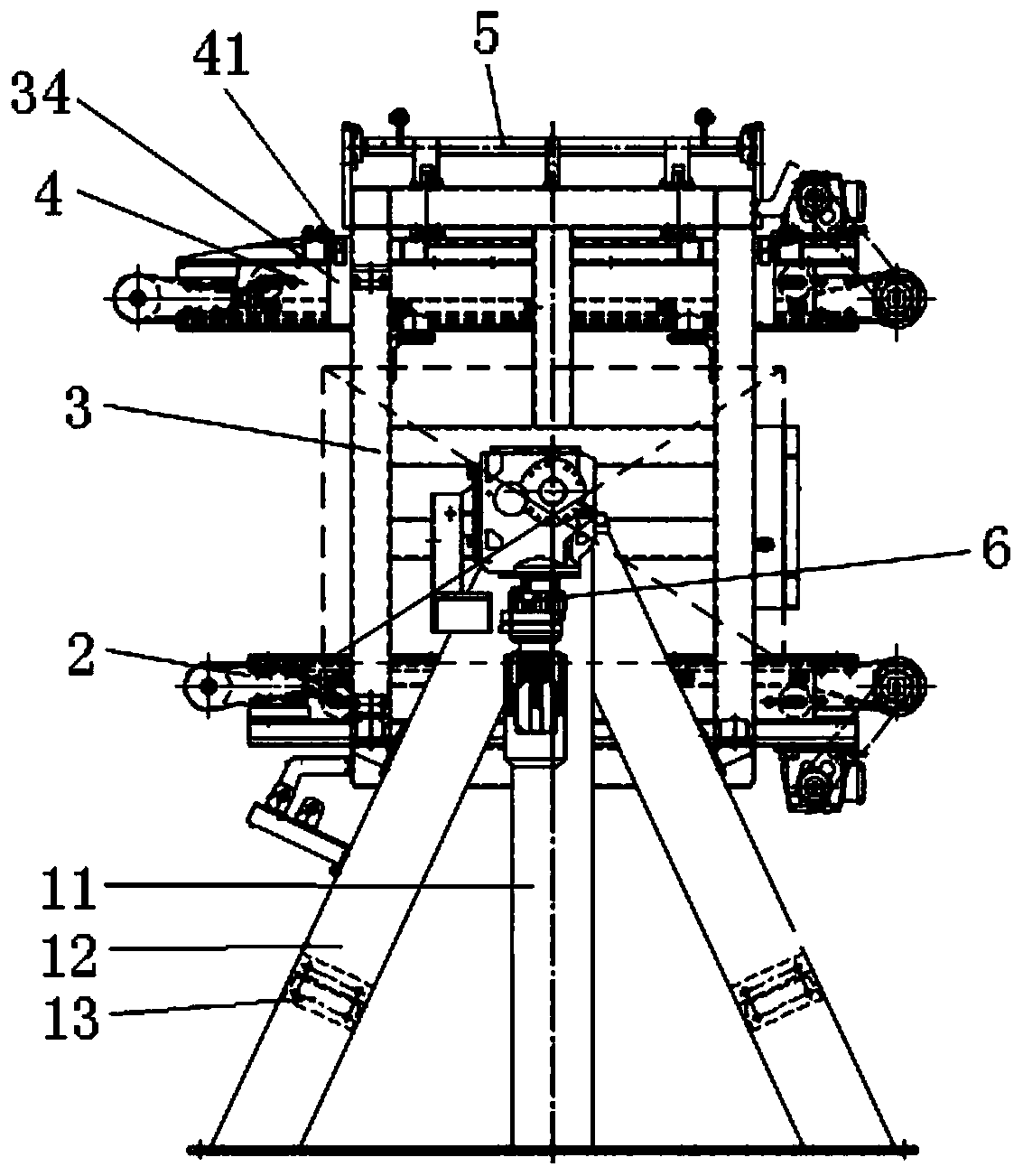

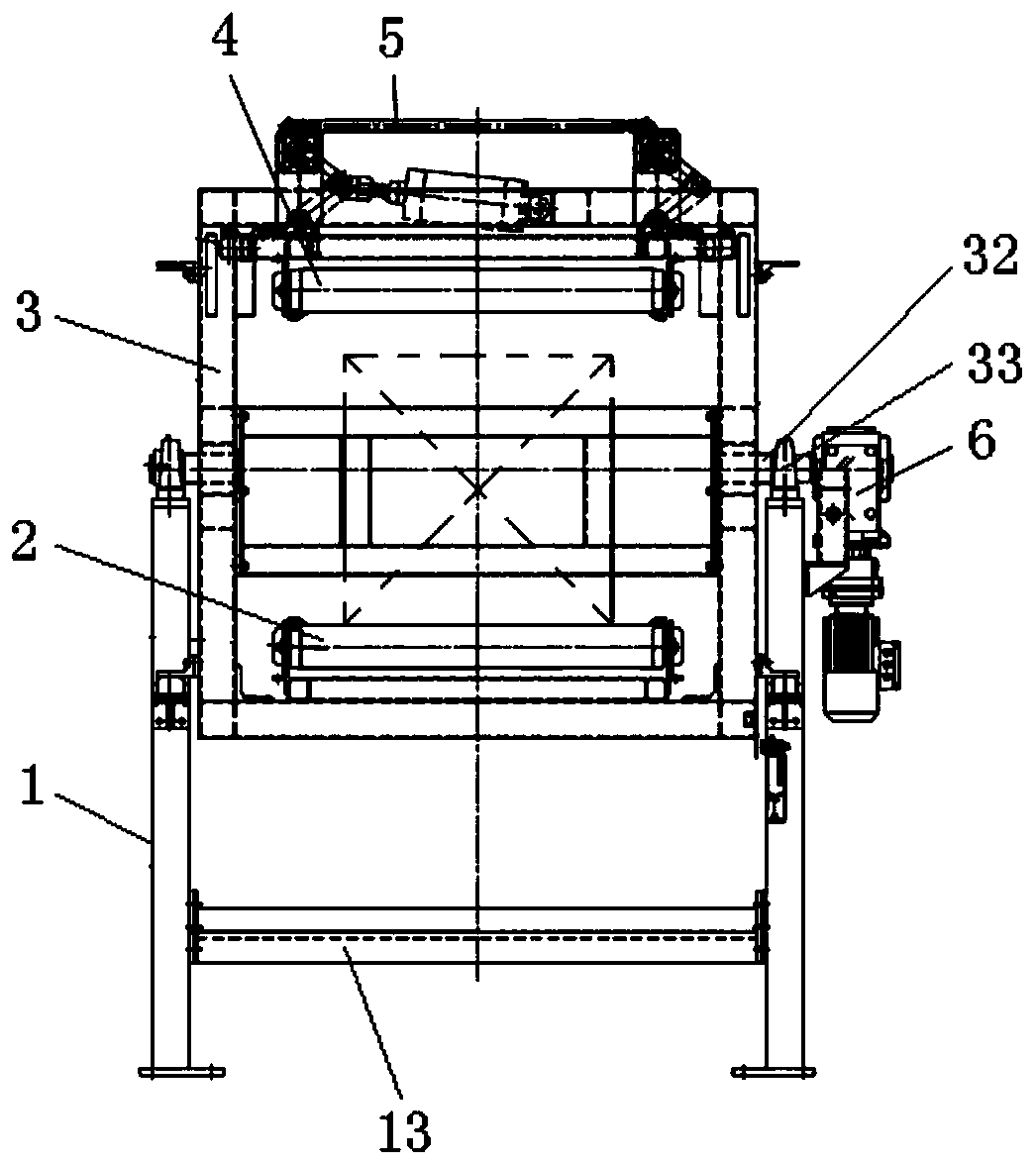

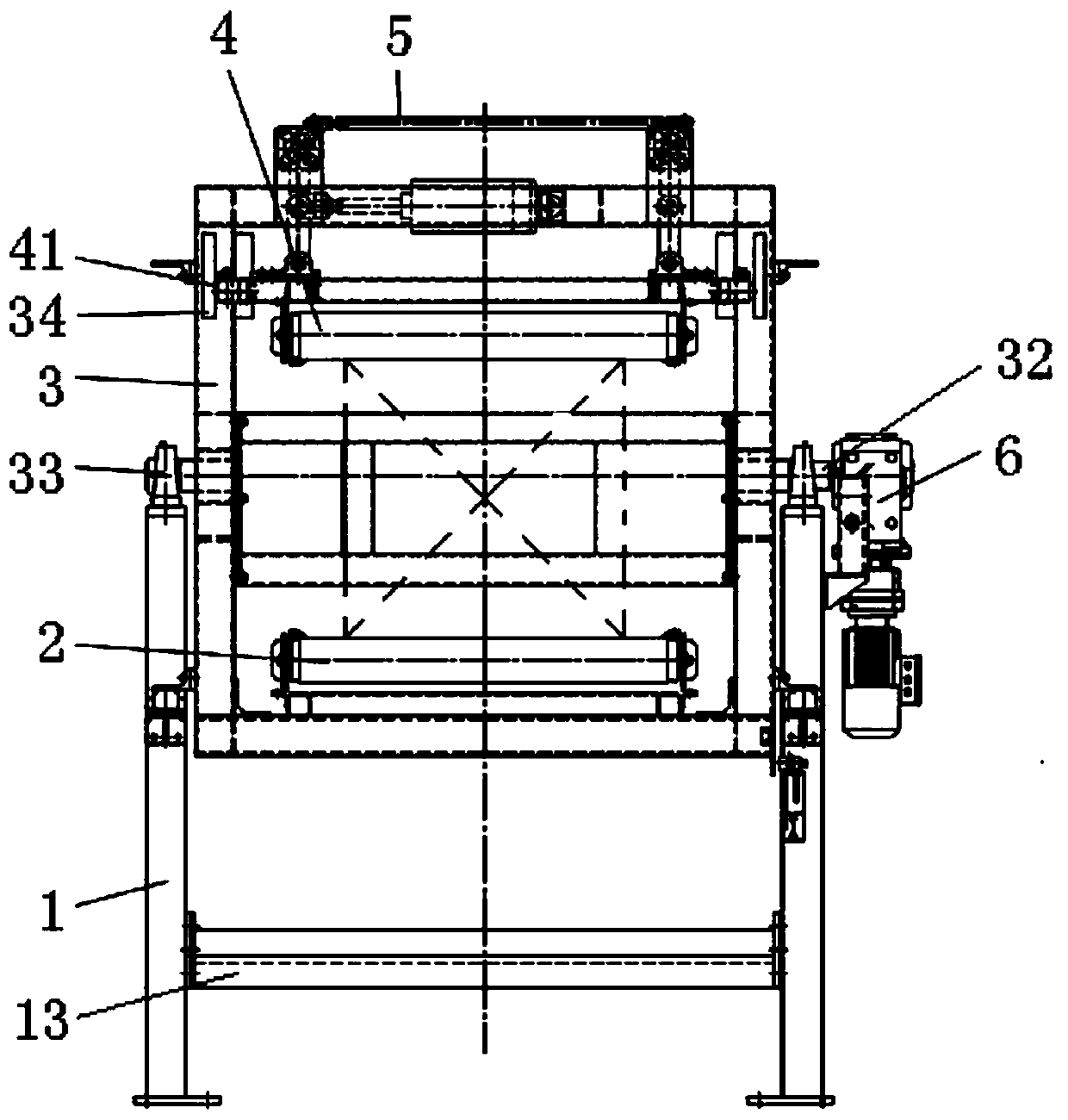

[0016] The self-locking box turning machine provided by the present invention includes a support frame 1, a rotating frame 3, and two conventional conveyors, one of which is a box-in conveyor 2, and the other is a box-out conveyor 4, both of which are belt conveyors. machine, on the supporting frame 1 is provided with a rotating frame 3, and the entering and exiting conveyors 2 and 4 are symmetrically arranged on the rotating frame 3, and the conveying surfaces of the entering and exiting conveyors 2 and 4 are arranged opposite to each other, and The box conveyor 4 is fixed on the rotating frame 3 through a self-locking synchronous lifting mechanism 5; wherein:

[0017] The swivel frame 3 includes a rectangular frame, two short shafts 32 are respectively arranged in the middle of both sides of the rectangular frame, and the outer ends of the two short shafts 32 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com