Film transfer scraper device

A scraper device and film transfer technology, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of inconvenient cleaning and replacement of blades, unstable blade swing, large resistance, etc., and achieve convenient and fast cleaning and replacement, and adjustment High precision and smooth swing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

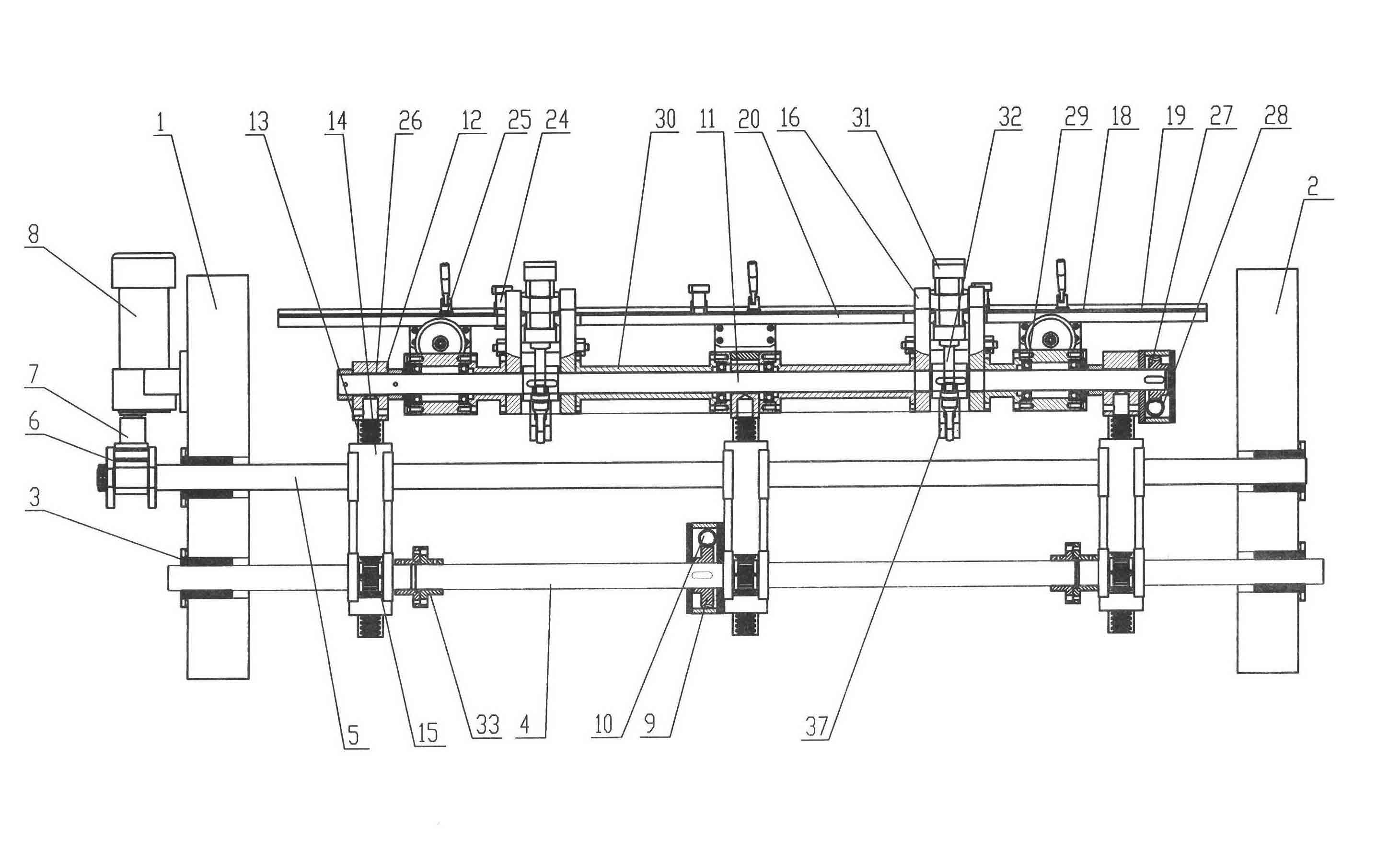

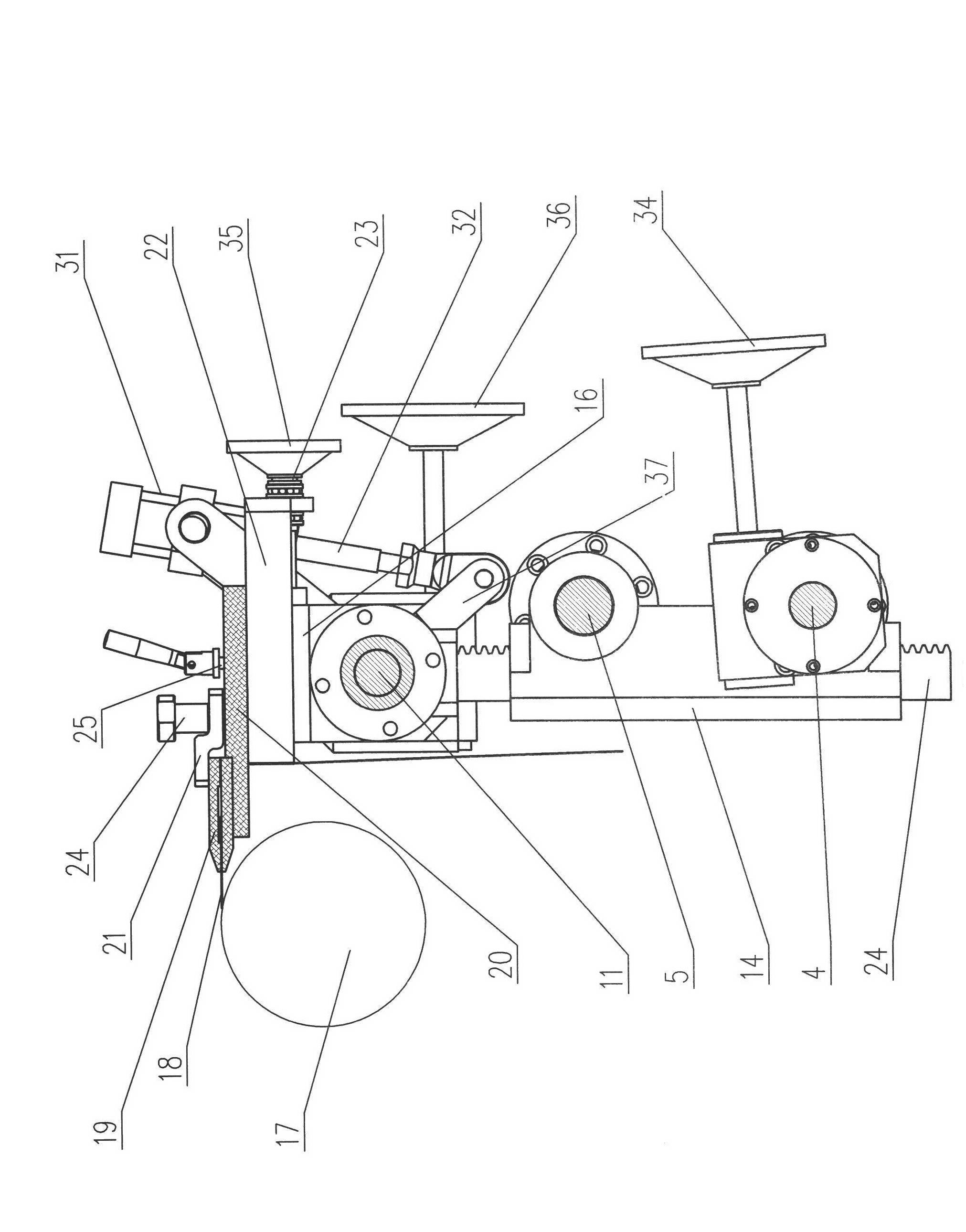

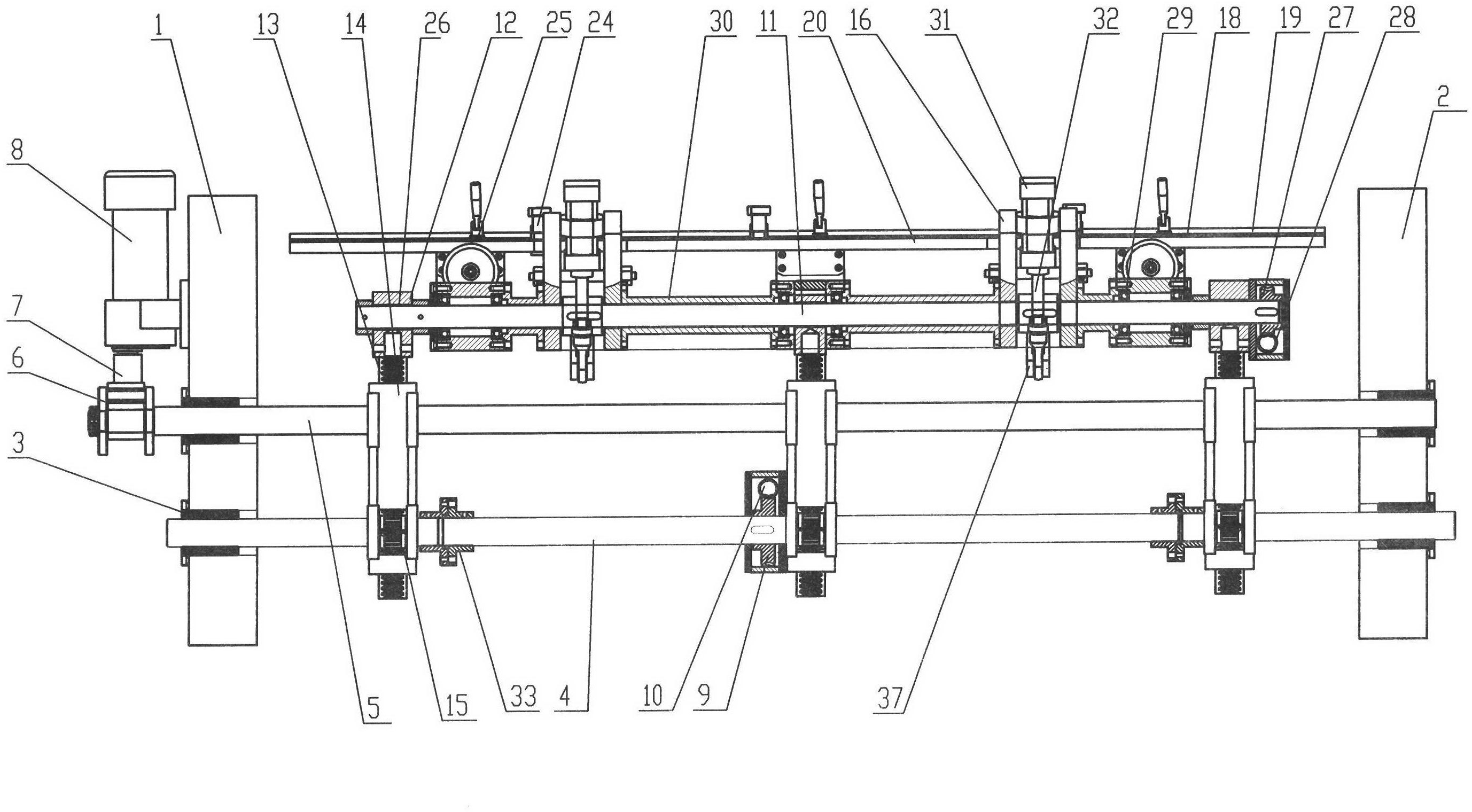

[0015] Such as figure 1 , figure 2 As shown, the film transfer scraper device includes: a left wallboard 1, a right wallboard 2, and a lower shaft 4 and a central shaft 5 respectively arranged between the left wallboard 1 and the right wallboard 2 through linear bearings 3 at both ends. One end of the central axis 5 protrudes from the left wallboard 1 and is connected with the swing sleeve 6. The swing sleeve 6 is connected with the deceleration motor 8 fixedly arranged on the left wallboard 1 through the eccentric shaft 7. The worm wheel 9 and the worm 10, the worm 10 is connected with the lower hand wheel 34, the upper shaft 11 is arranged above the middle shaft 5 between the left wallboard 1 and the right wallboard 2, and three racks are arranged on the upper shaft 11 to fix Seat 12, the lower end of rack fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com