Micro-control air cylinder wind-water pressure testbed

A technology of air storage cylinder and wind water pressure, which is applied in the direction of railway vehicle testing, liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of affecting the quality of the working environment, high noise, complicated operation, etc., so as to facilitate the observation of leakage locations , noise reduction, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further describe the present invention in conjunction with the accompanying drawings.

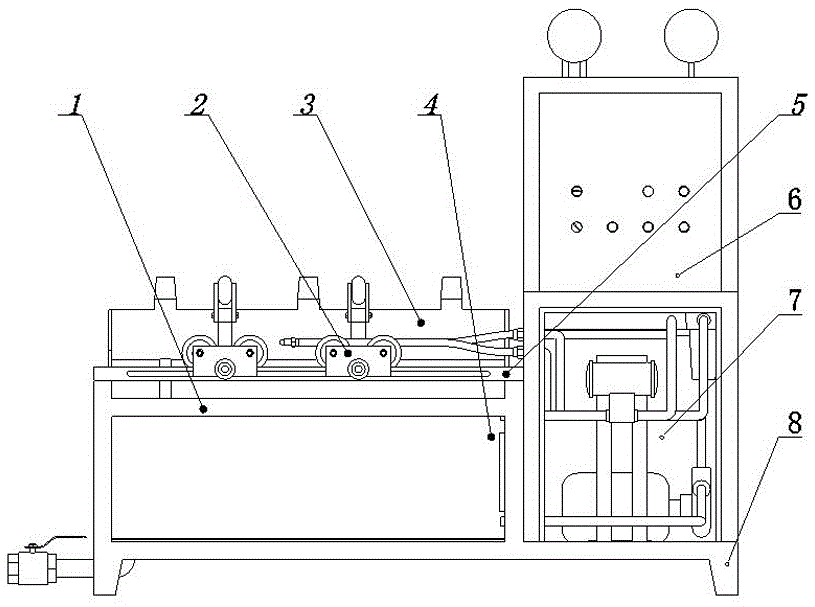

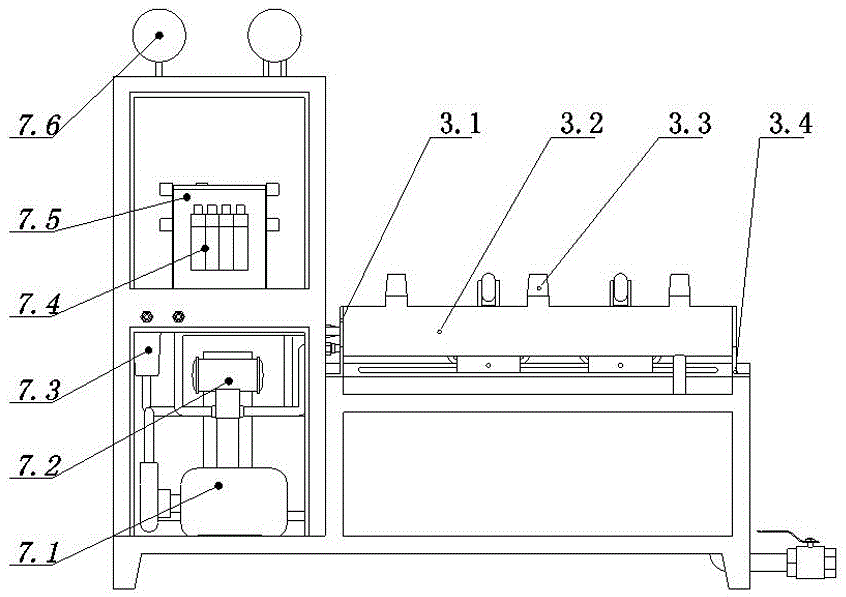

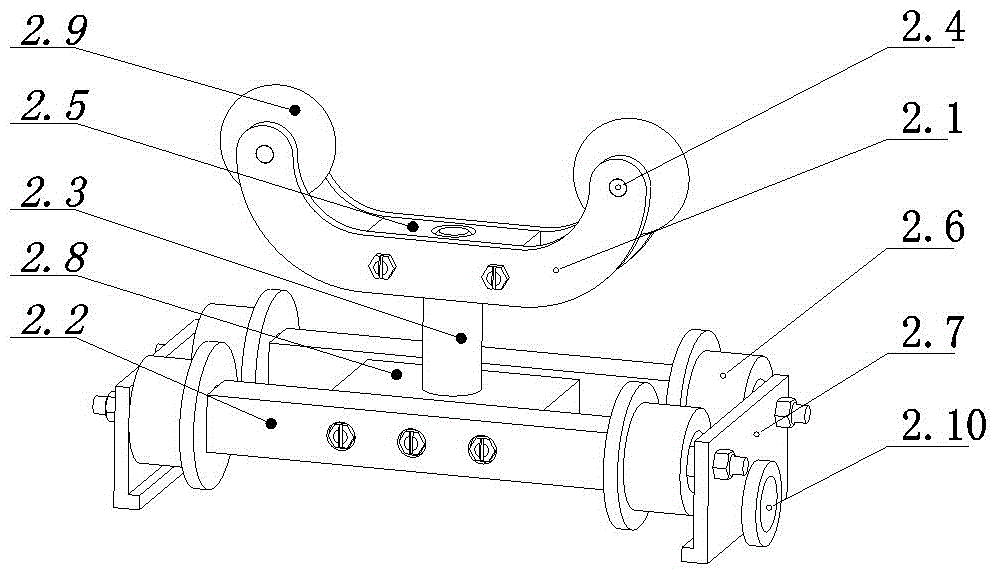

[0027] Such as figure 1 and figure 2 As shown, the device for testing the performance of a railway vehicle air storage cylinder includes: a frame 1, an air storage cylinder fixture 2, a water supply and air supply system 7, a pressure relief cylinder 3, a water tank 4, and a casing 6. Frame 1 is a stepped shape with low left and high right, legs 8 are welded to the bottom of frame 1, water tank 4 is welded to the left side inside frame 1, guide rails 5 and pressure relief cylinders 3 are arranged front and back on frame 1 above water tank 4. The two guide rails 5 are parallel to each other and placed horizontally, and are fixed to the frame 1 by screws, and a pair of clamps 2 for the air storage cylinder are placed on the guide rails 5 . The water supply and air supply system is on the right side of the frame 1, and the water pump 7.1, the pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com