High-speed hydraulic machine

A hydraulic press, high-speed technology, applied in the field of forging machinery, can solve problems such as poor control and high installed power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

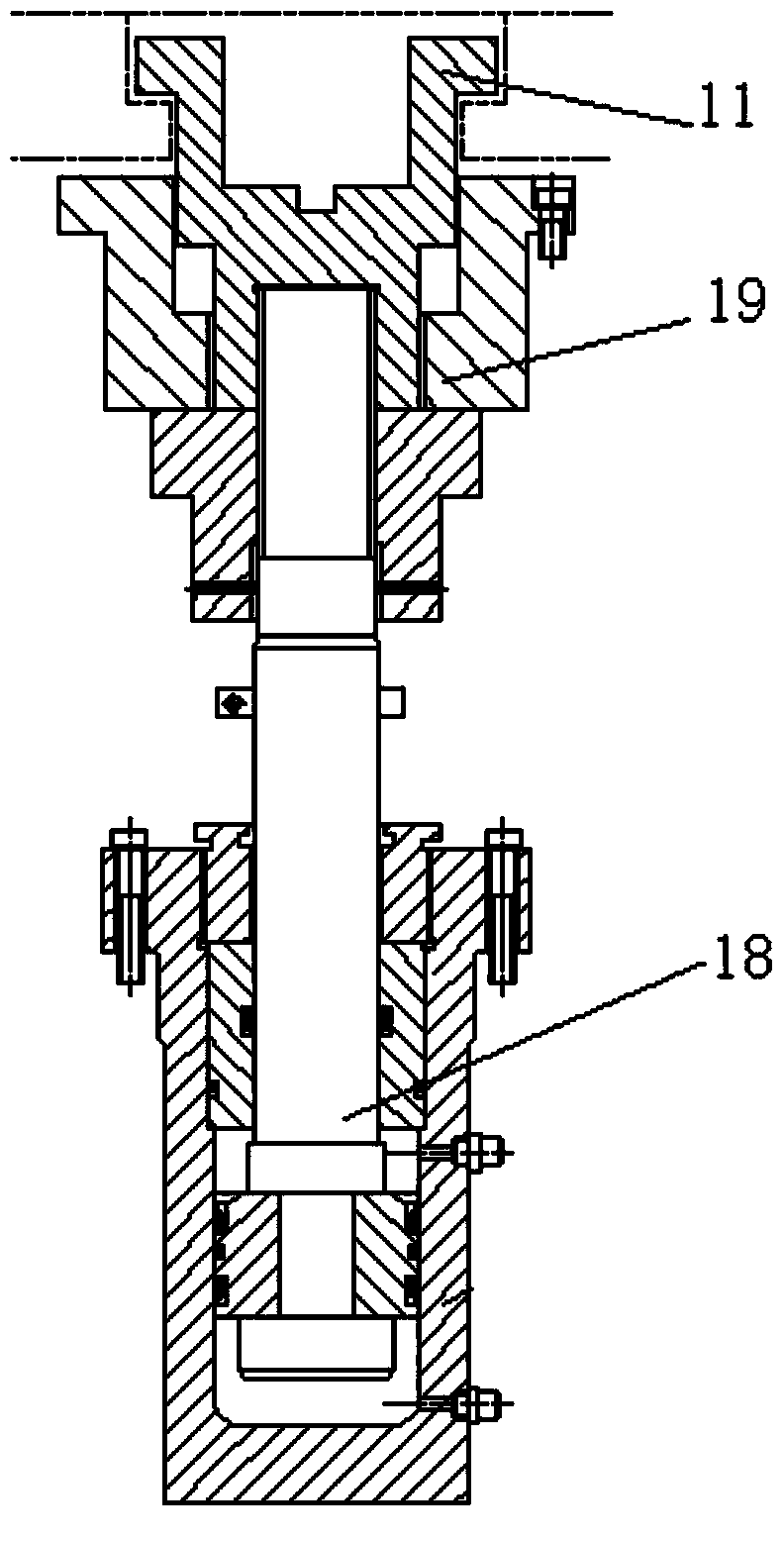

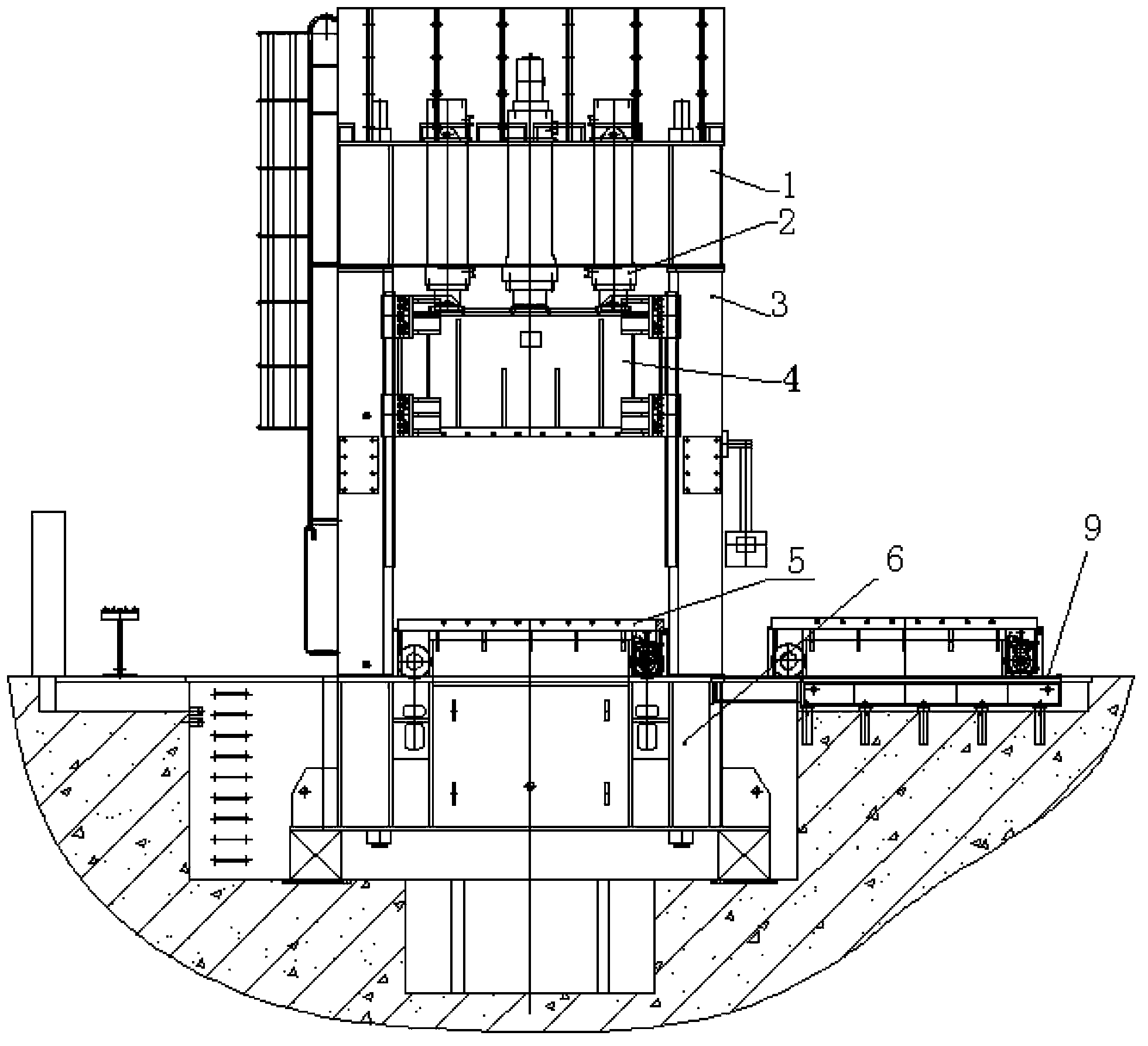

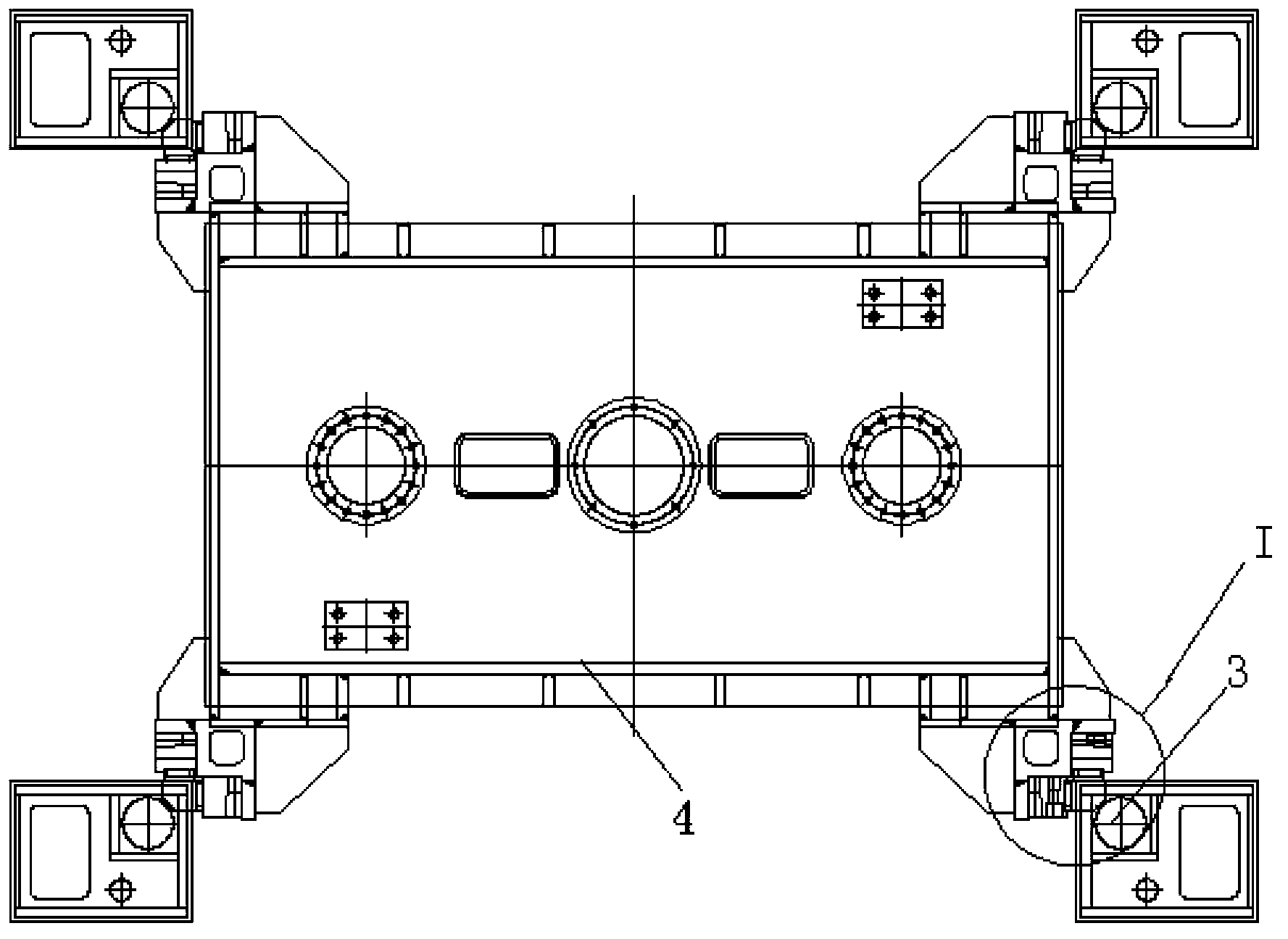

[0024] Referring to the accompanying drawings, a high-speed hydraulic machine includes a frame-type support between the column 3 and the upper and lower beams 1 and 6. The upper beam 1 is fixedly equipped with a main oil cylinder 2 with a downward piston rod, and the piston rod of the main oil cylinder 2 The lower end is equipped with a slider 4, and the slider 4 and the column 3 are slid and guided through an adjustable guide rail guide mechanism. The adjustable guide rail guide mechanism includes a slider guide plate 5, an adjustable guide plate 8 with a slope, and a guide plate 7. The slider guide plate 5 is welded on the slider 4, and the guide plate 7 is slidingly matched with the column 3. An adjustable guide plate 8 with a slope is installed between the slider guide plate 5 and the guide plate 7, and the lower beam 6 is erected There is a side shifting workbench 9, the bottom end of the side shifting workbench 9 is provided with rollers 10, and positioning holes matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com