Visual guidance feeding method for automobile manufacturing production line

A visual guidance and automobile manufacturing technology, applied in the field of automobile manufacturing, can solve the problems of unreachable position accuracy, high position accuracy requirements, fast grasping speed, etc., to meet the production cycle, fast workpiece positioning speed, and high feeding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions will be clearly and completely described below in conjunction with the embodiments of the present invention.

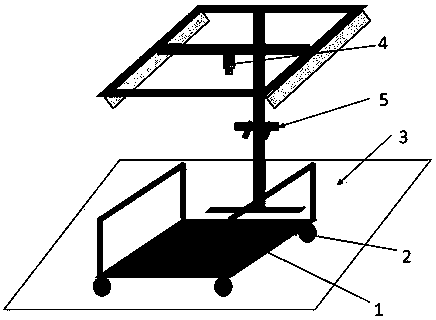

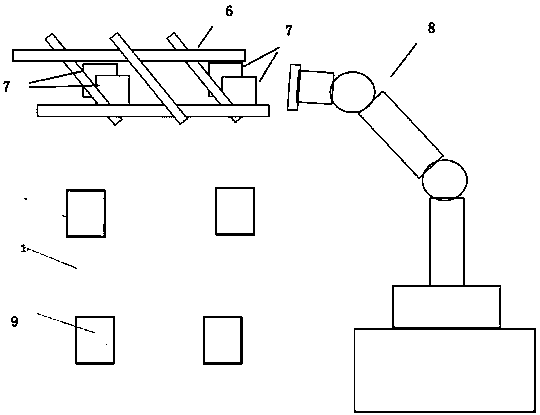

[0024] In automobile manufacturing and production, when the workpieces such as the front floor of the automobile come in, the materials are stacked and transported to the loading station by the feeding truck. Due to the large material frame of the material truck, the position of the workpiece in the material frame is free, and the direct use of a laser with high positioning accuracy but a small photographing range will cause the problem that the positioning hole is outside the photographing area. In order to enable the laser to capture the position of the positioning hole on the workpiece, before the fine positioning step, a rough positioning function is added to give the approximate offset position of the workpiece in the feeder (Δx 1 , Δy 1 , Δz 1 , ΔRx, ΔRz). The vision system sends the calculated deviation value to the robot, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com