Automatic ice cream stick feeding system

A technology of automatic feeding and ice cream sticks, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve the problems of messy feeding directions and low feeding efficiency of ice cream sticks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

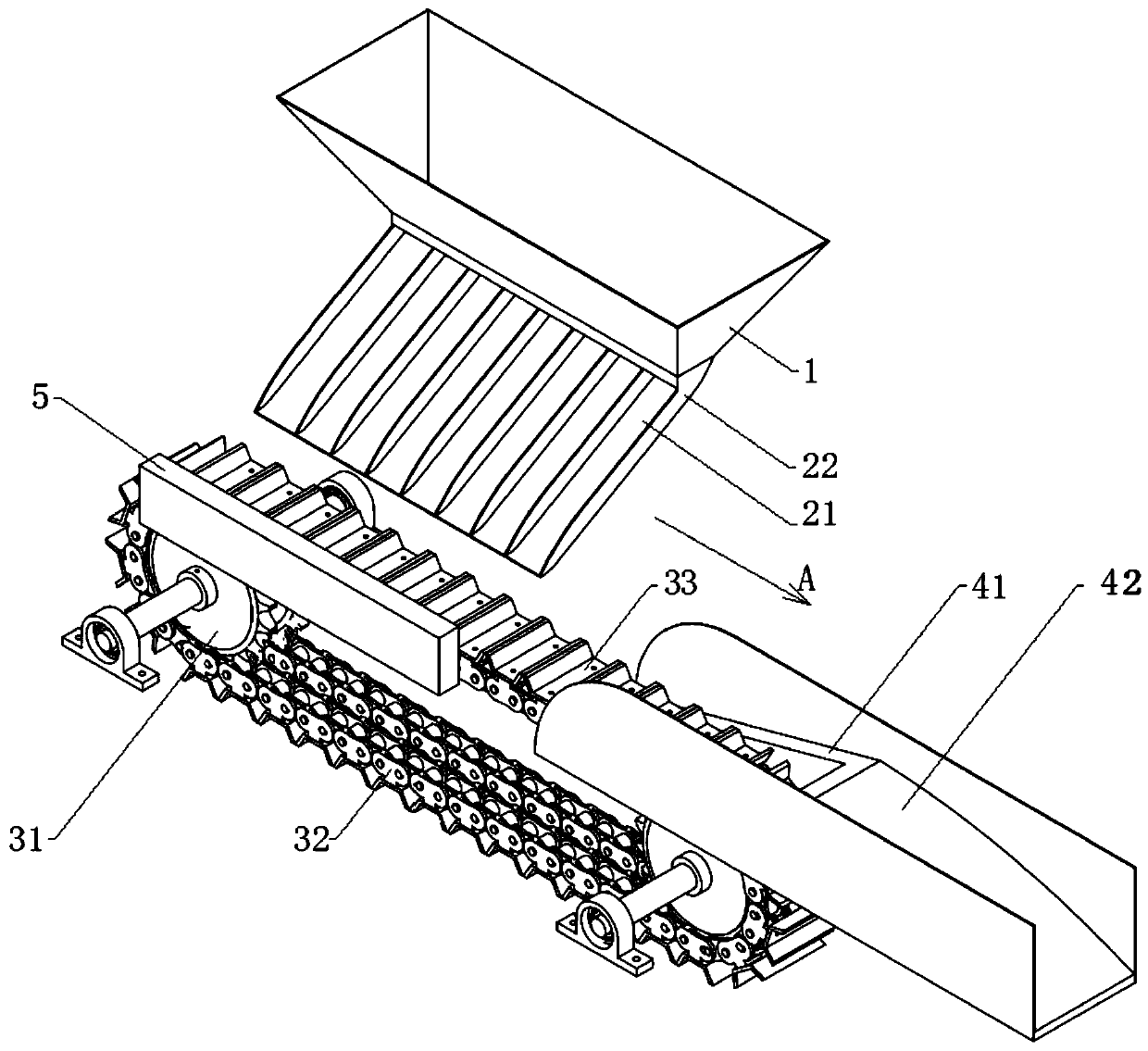

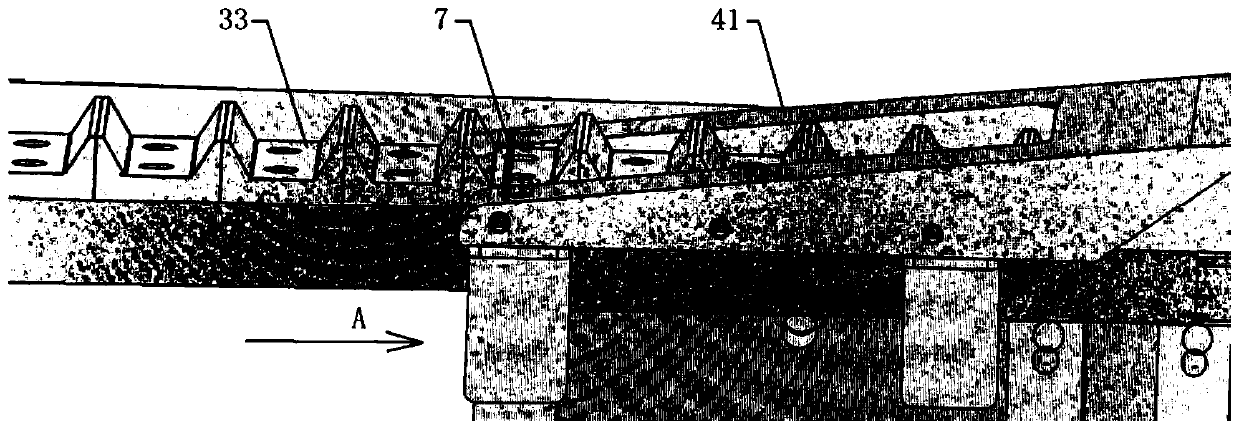

[0036] see Figure 1 to Figure 3 , an automatic feeding system for ice cream sticks provided by an embodiment of the present invention, the automatic feeding system for ice cream sticks includes:

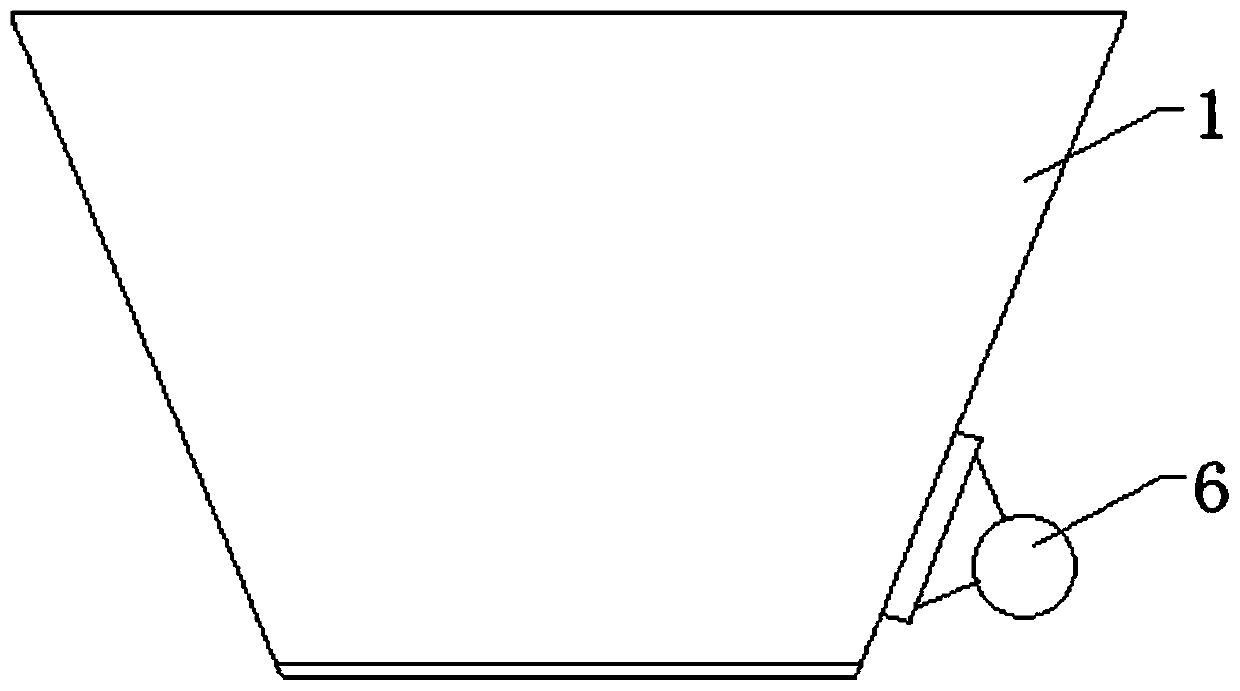

[0037] The feeding bin 1 is funnel-shaped, and the outlet of the feeding bin 1 is elongated. Drop into the ice cream stick from the top of the feed bin 1, and the ice cream stick slides out from the elongated outlet at the bottom of the feed bin 1.

[0038] Feed chute, described feed chute comprises base plate 21 and some wall plates 22, and wall plate 22 is mutually parallel and is arranged on the base plate 21 at intervals; The first end of described feed chute is with described feed bin 1, the second end of the feed chute is opposite to the first end, and the first end of the feed chute is higher than the second end, so that the ice cream stick is drawn from the second end by gravity One end slides to the second end; the wall plate 22 extends from the first end to the second en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com