Intelligent preparation method of liquid slowly-controlled-release fertilizer

A controlled-release fertilizer and intelligent preparation technology, which is applied in the program control of sequence/logic controller, fertilizer mixture, electrical program control, etc., can solve the problems of restricting development, single fertilization, affecting fertilizer quality and nutrients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075]All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0076] Any feature disclosed in this specification (including any appended claims, abstract), unless otherwise stated, may be replaced by alternative features that are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

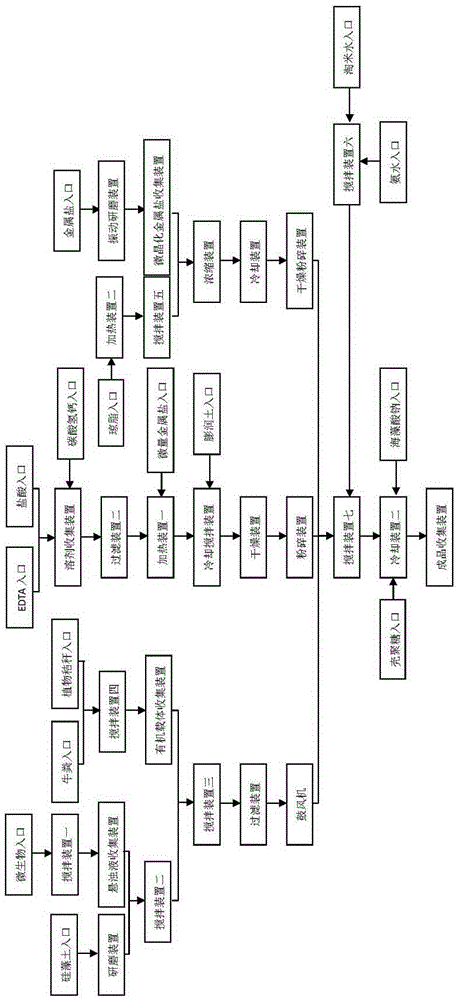

[0077] Such as figure 1 As shown, an intelligent preparation system for liquid slow and controlled release fertilizer, which includes: induction module, grinding module, stirring module, sugar water ratio module, blast module, temperature detection module, temperature control module, wind measurement module, prompt module , PH detection module, heating module, material module, refrigeration module, drying module, crushing module, filtration module; vibration module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com