Function test split-mounting table for automobile components

A technology for functional testing and auto parts, applied to workbenches, hand-held tools, manufacturing tools, etc., can solve problems such as the difficulty of rear window sunshades, affecting the on-time delivery of vehicles, and scratches on the rear windshield, so as to meet the production cycle , small footprint, easy to learn and understand the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The design and manufacture of a special sub-assembly station for automobile inspection can achieve problem forward control, detect abnormal vehicle functions in advance, and unqualified parts will not be loaded, completely eliminating a quality problem and reducing the pressure of debugging and delivery; it can be used anytime and anywhere, occupying Small space, push-button switch, easy to operate, equipped with electronic modules, reliable work, durable, minimum labor intensity, reduce bicycle cost, save working hours, and improve employee satisfaction.

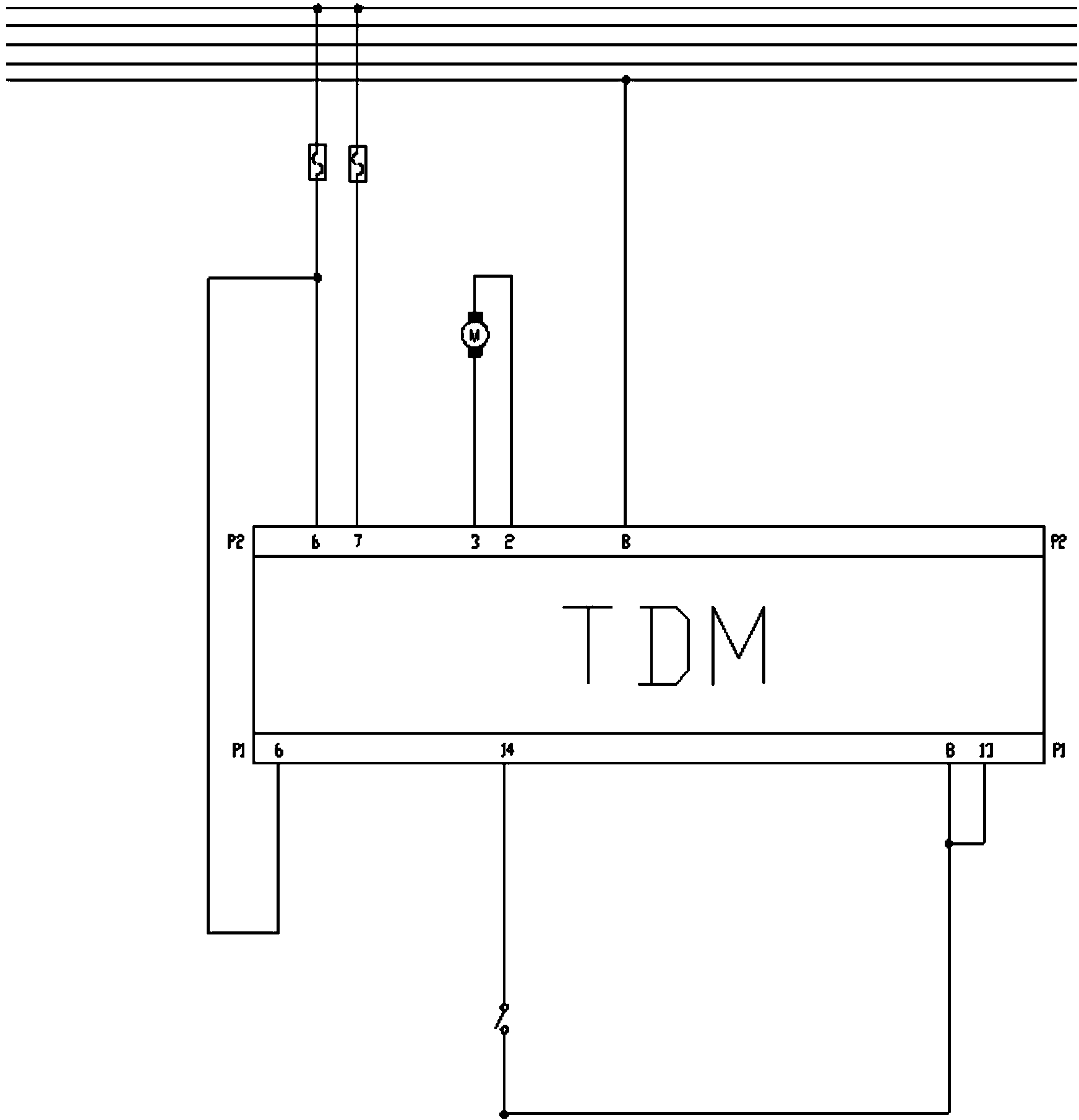

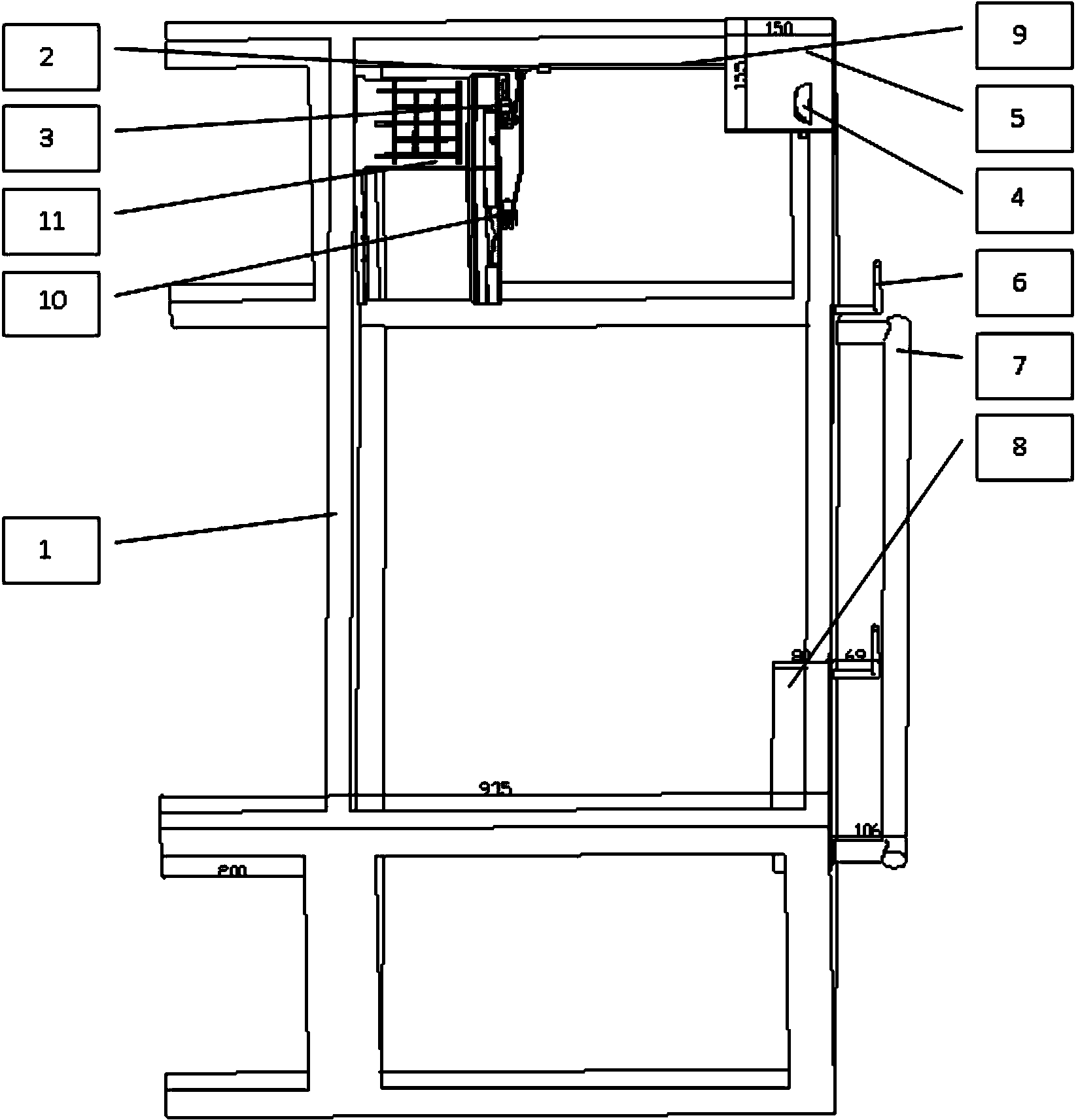

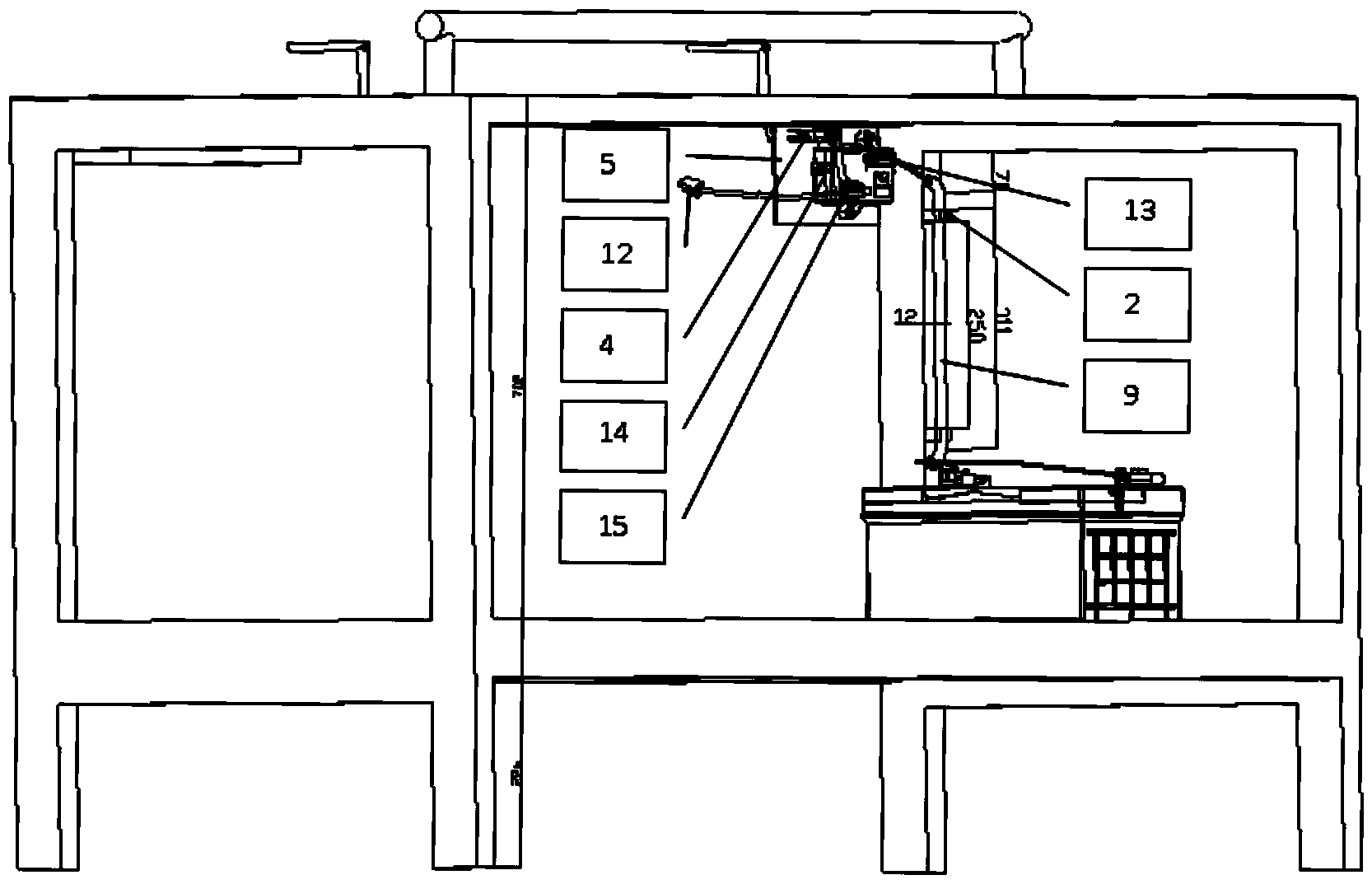

[0026] see Figure 2-4 Specifically, the dispensing table 1 is equipped with electrical components, and the table is provided with a support for supporting the electric rear window sunshade. The dispensing table 1 is formed by cutting and welding a hollow square tube with a specification of 30mm×30mm×1.5mm. Ensure the stability and reliability of the device. Welded sub-package table 1 length x width x height: 1450mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com