Front brake subassembly clamper for vehicle

A front brake and clamping technology, used in manufacturing tools, motor vehicles, transportation and packaging, etc., can solve problems such as difficulty in operation, inability to apply torque, and inability to tighten bolts, so as to meet the conditions of torque application, meet the requirements of sub-assembly, Good positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

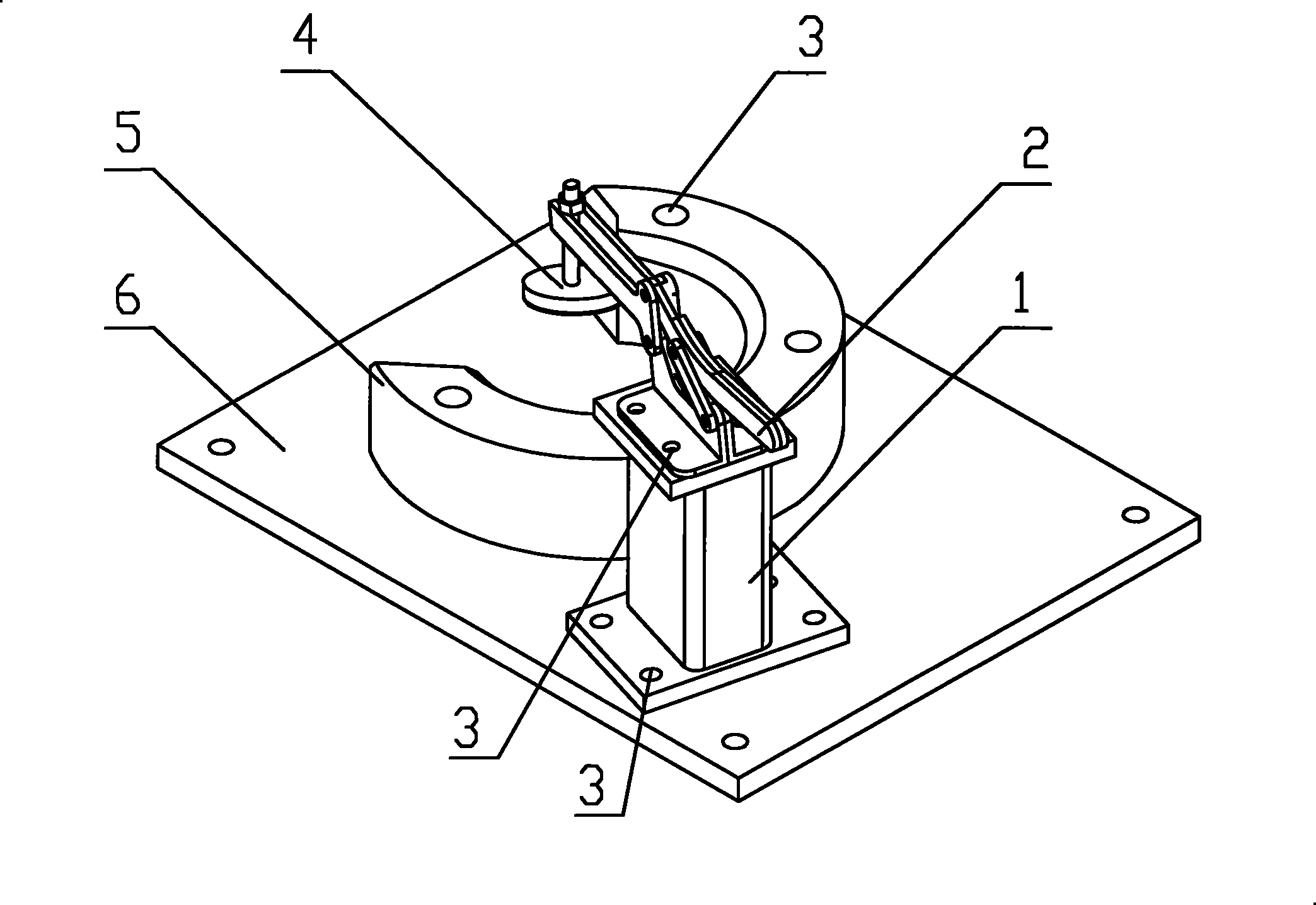

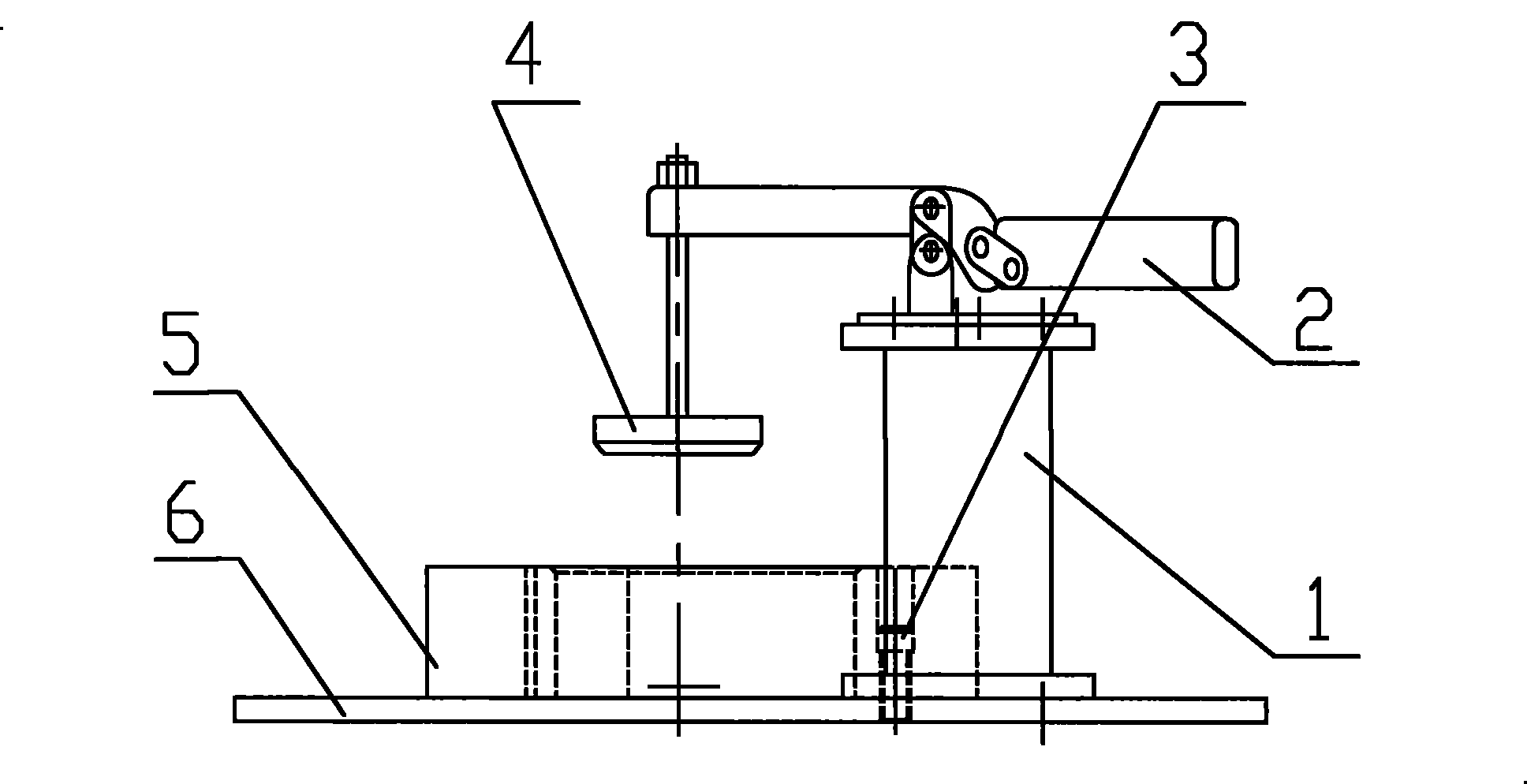

[0012] Such as figure 1 and figure 2 As shown, the fixture includes a clamp base 1, a clamp 2, a clamp head 4, a positioning ring 5, a base plate 6, and the like. The clamp base 1 and the positioning ring 5 are respectively fixedly connected to the bottom plate 6 , for example, bolts 3 may be used for fixed connection. The clamp base 1 is located outside the positioning ring 5, the clamp 2 is fixed on the top of the clamp base 1, the center of the clamp head 4 on the clamp 2 is aligned with the center of the positioning ring 5, and the positioning ring 5 is a circular platform with a fracture . The locating ring 5 is a circular platform with a fracture, the inner circular surface of the locating ring 5 matches the outer circular stepped surface of the front brake assembly, and the fracture has an outward oblique cut surface, which is adapted to the size of the front brake assembly bump.

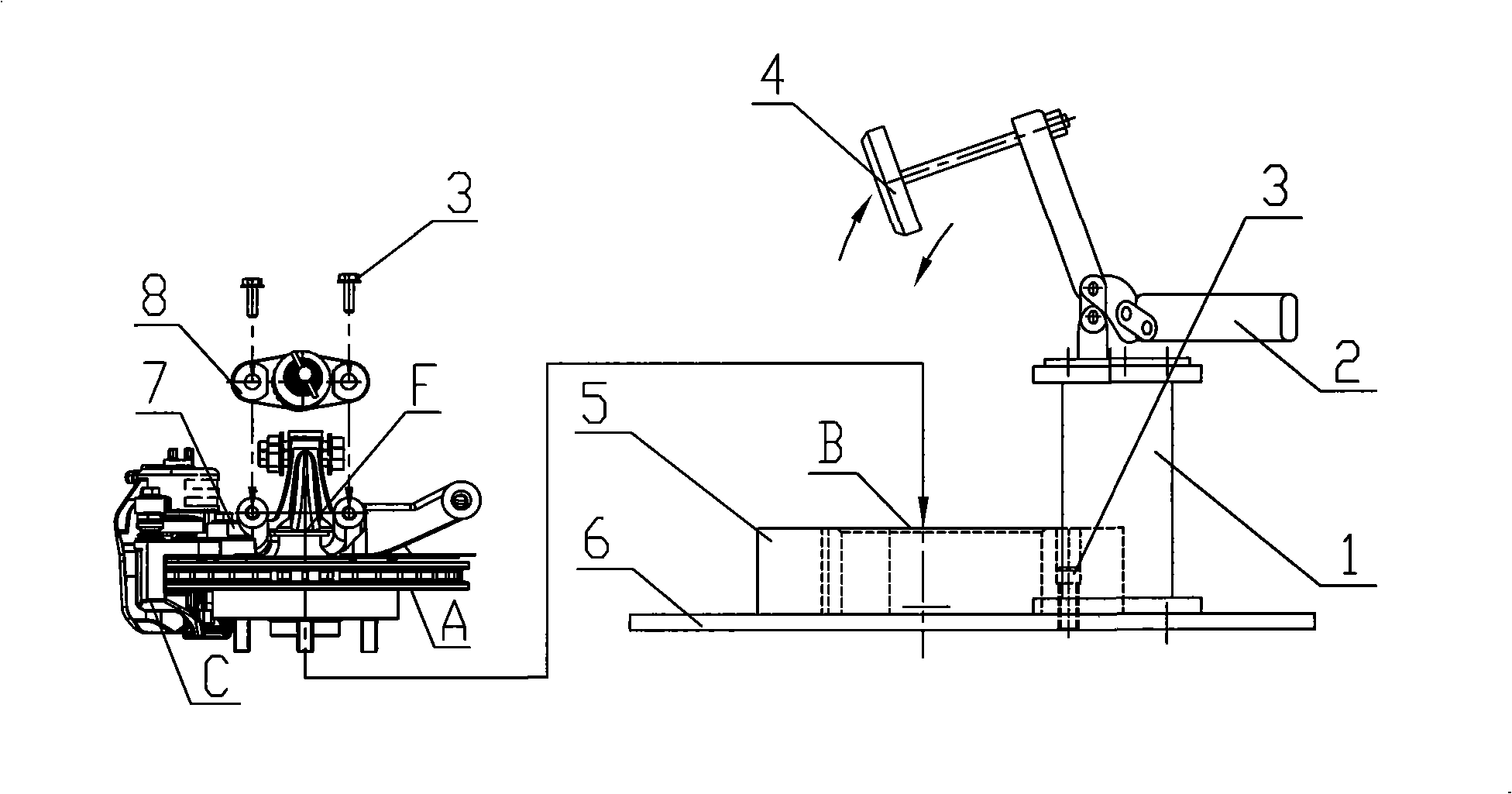

[0013] Such as image 3 and Figure 4 As shown, the use method of the fixture is: f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com