Overall plastic microcosmic laminar composite and its preparation method

A layered composite material and microcosmic technology, which is applied in the field of water-emulsion-based paste material tube packaging, can solve the problems of consuming scarce energy and aluminum resources, complex processing technology, and high processing costs, and achieve the goal of saving oil resources and aluminum resources, reliable compressive strength, simple and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Polyethylene resin, ratio: 75%, the proportion of polyethylene resin: high-density polyethylene 30%, low-density polyethylene 30%, linear low-density polyethylene 15%;

[0009] Aromatic nylon chooses nylon 6, ratio: 16%;

[0010] Montmorillonite NB901, ratio: 3%;

[0011] Choose ethylene-vinyl acetate copolymer, ratio: 6%.

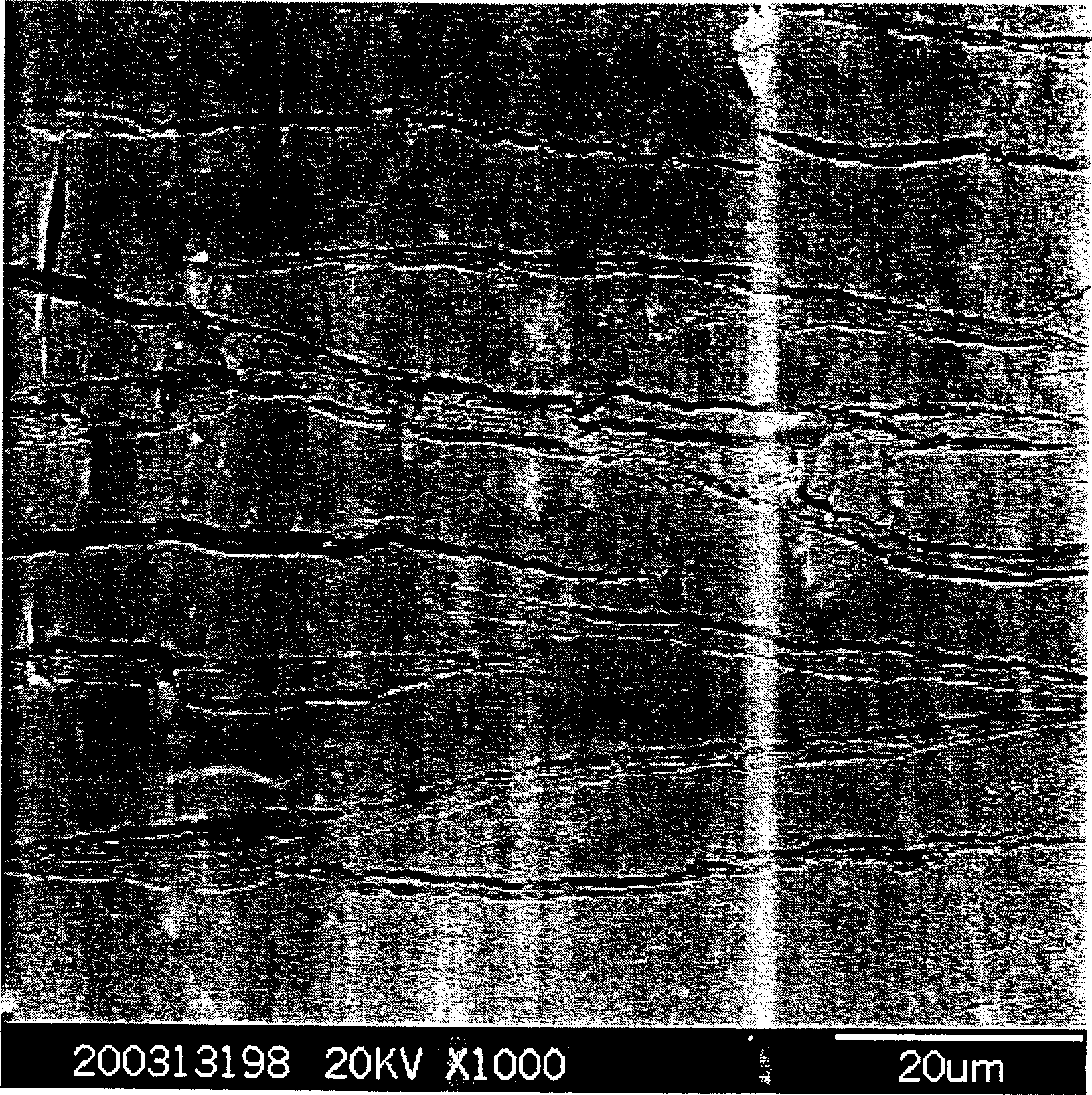

[0012] The above-mentioned components are mixed and granulated, and then compressed into a sheet using an extrusion calender to form a microscopic layered composite structure sheet, as shown in the attached electron microscope photo of the product.

Embodiment 2

[0014] Polyethylene resin, ratio: 85%;

[0015] Aromatic nylon chooses nylon 66, ratio: 5%;

[0016] Montmorillonite NB908, ratio: 3%;

[0017] Choose glycerol methacrylate graft, proportion: 7%. All the other are with embodiment 1.

Embodiment 3

[0019] The proportion of polyethylene resin is 80%, the proportion of nylon 1010 is 8%, the proportion of montmorillonite NB901 is 4%, and the proportion of glycerin methacrylic acid graft is 8%. Color masterbatch is also added in the batching, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com