Patents

Literature

94results about How to "Reduce casting difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

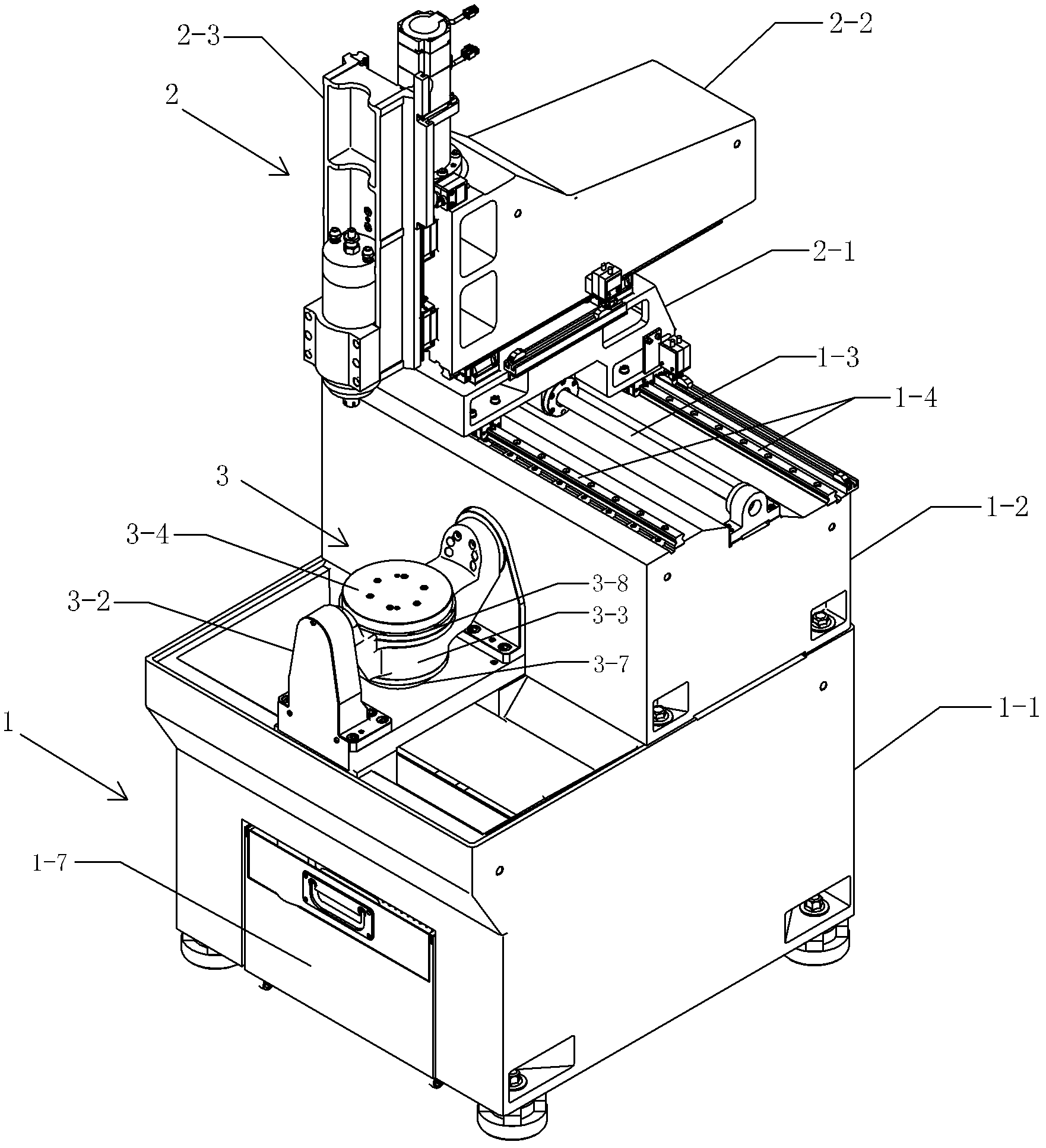

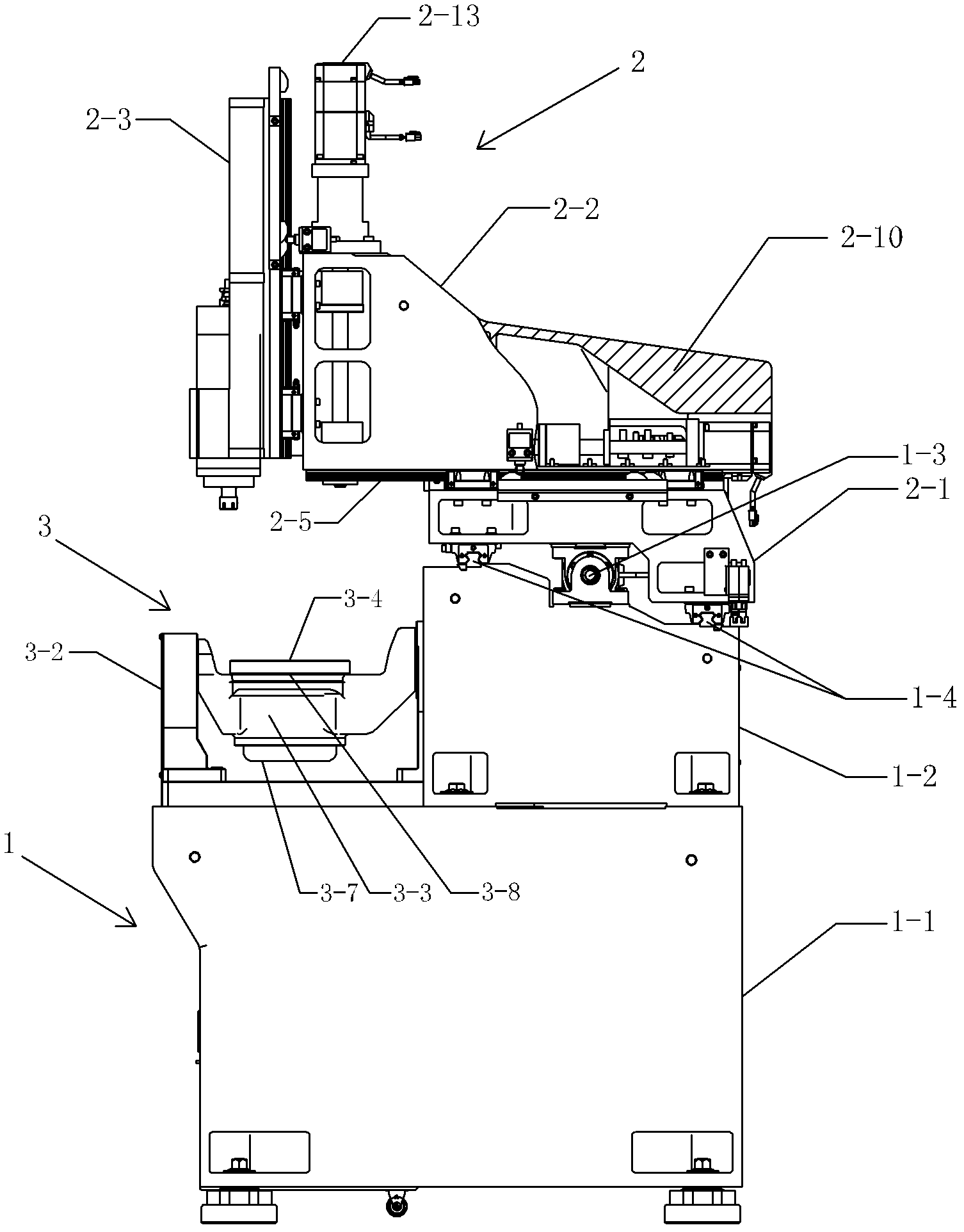

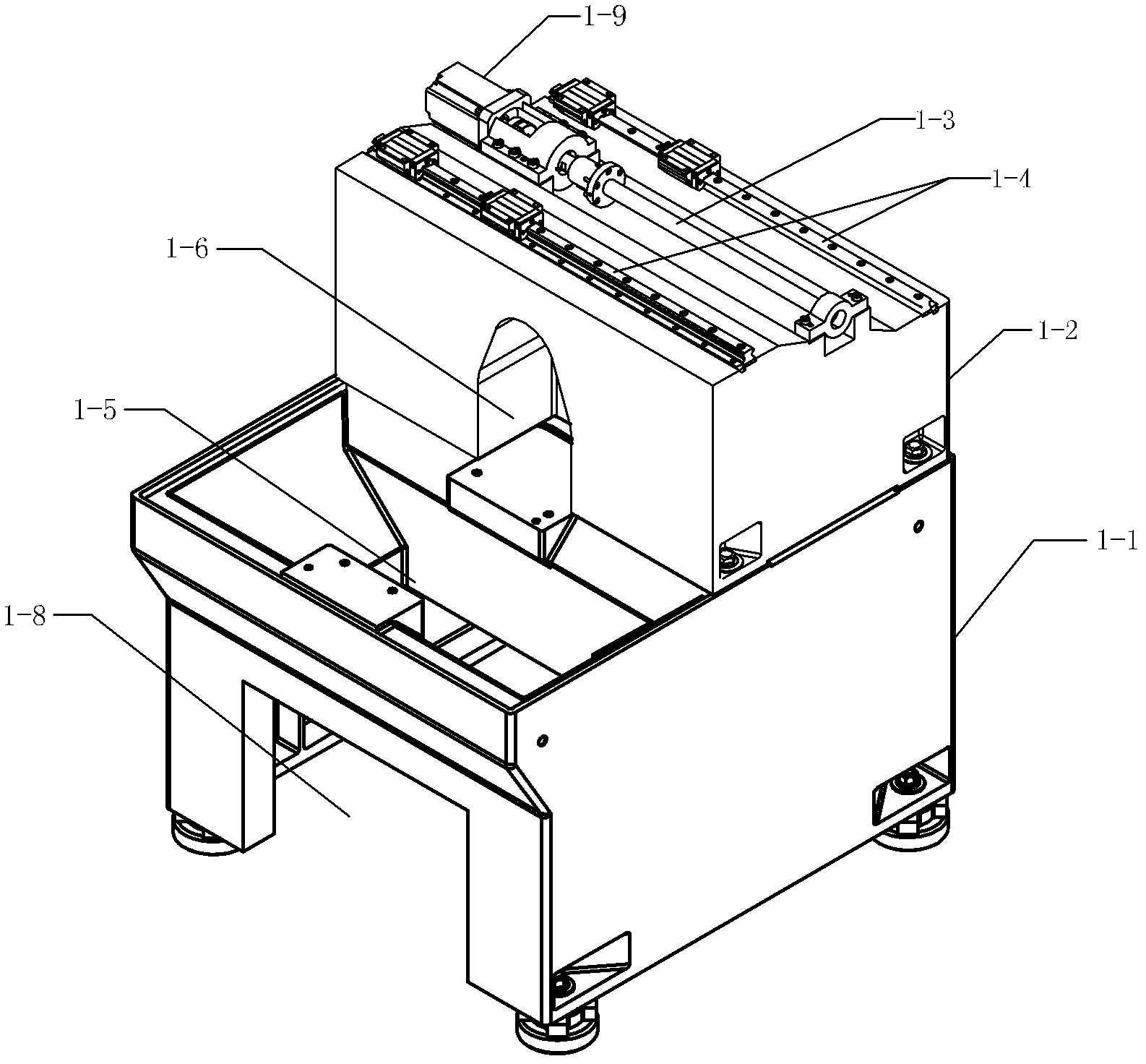

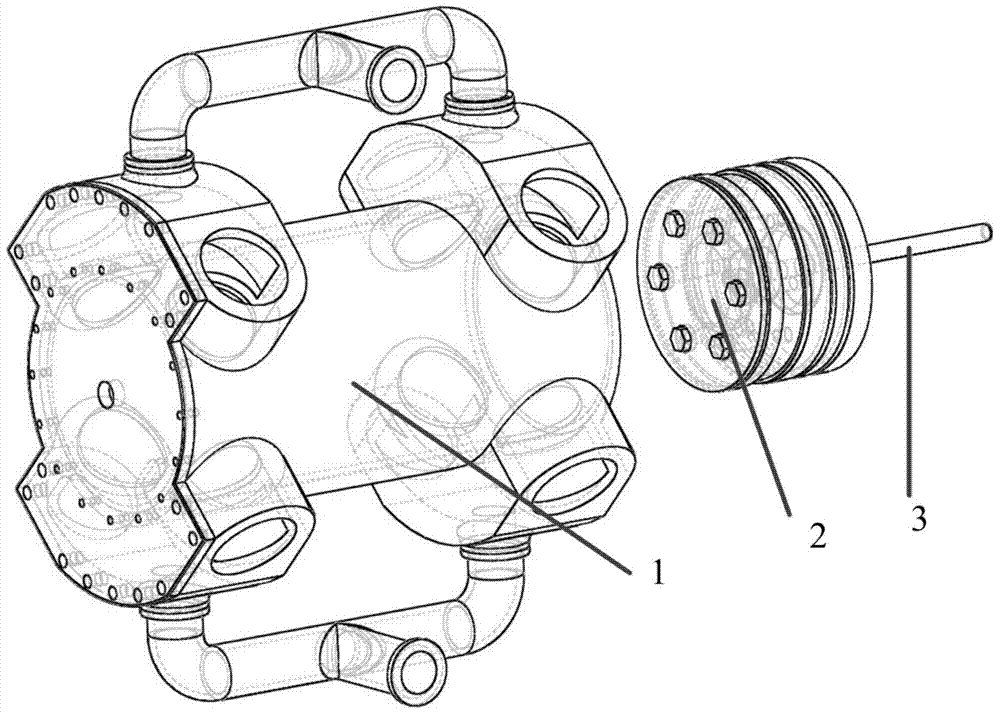

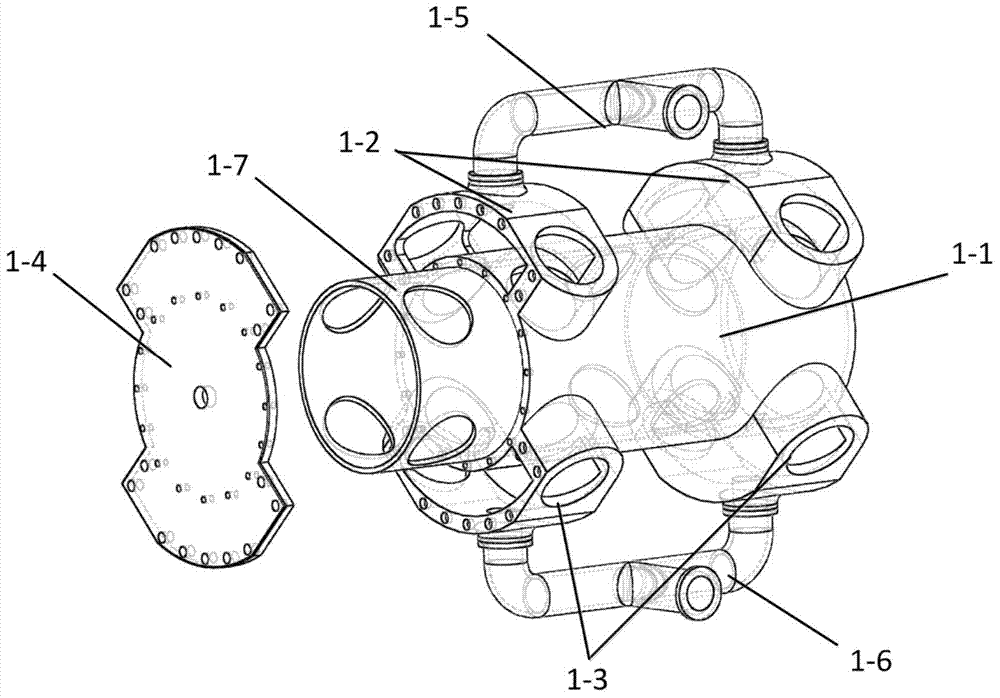

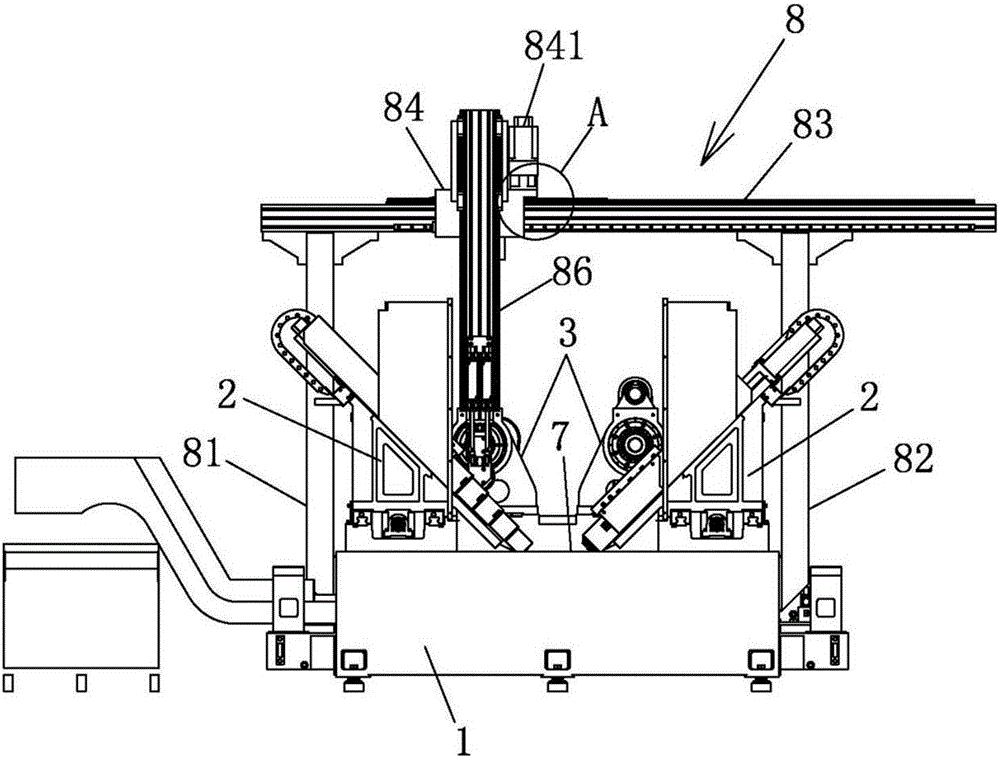

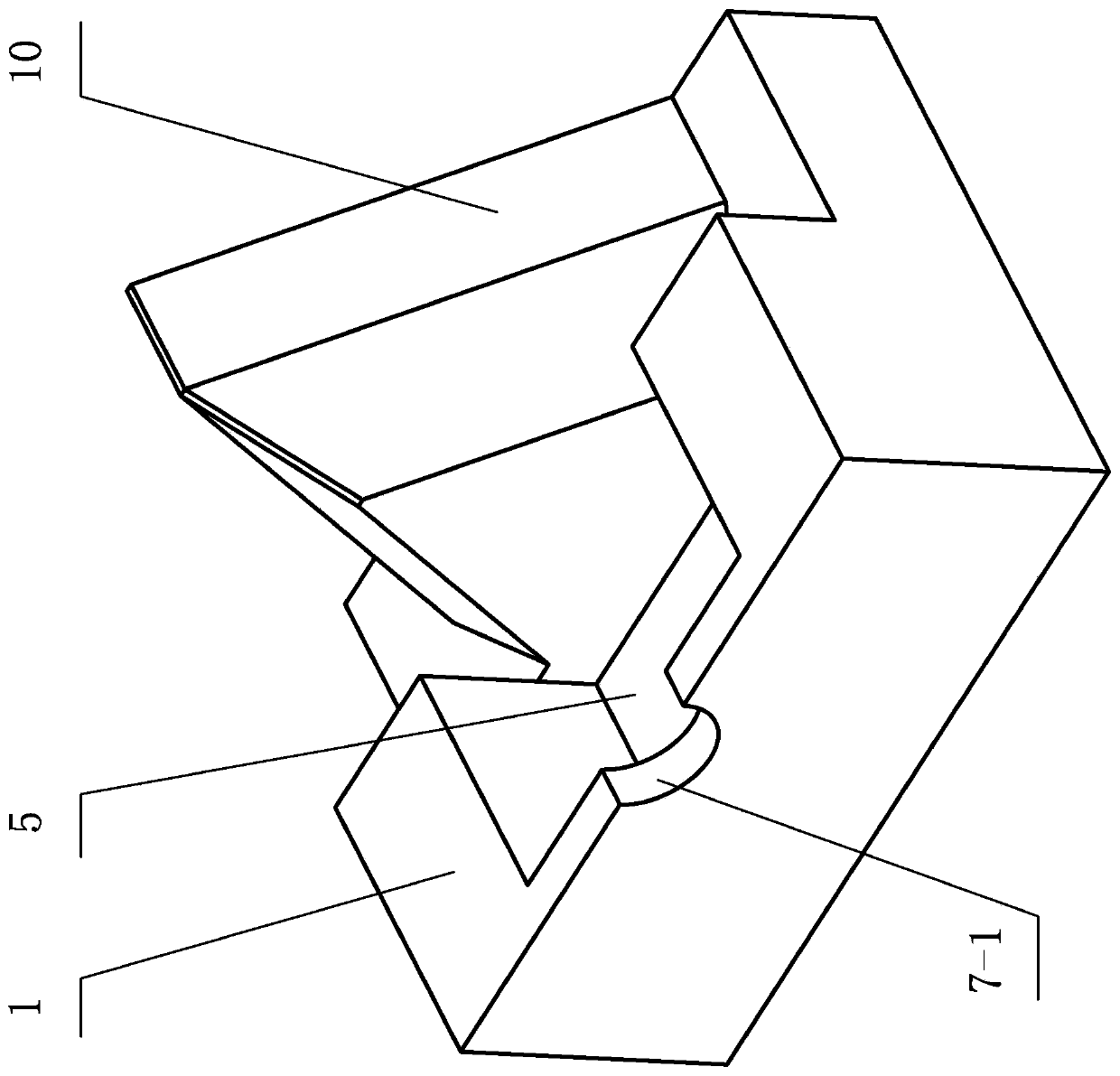

Small-sized five-axis machining center

InactiveCN102672472AReduce weightEasy to planLarge fixed membersMetal working apparatusBall screwEngineering

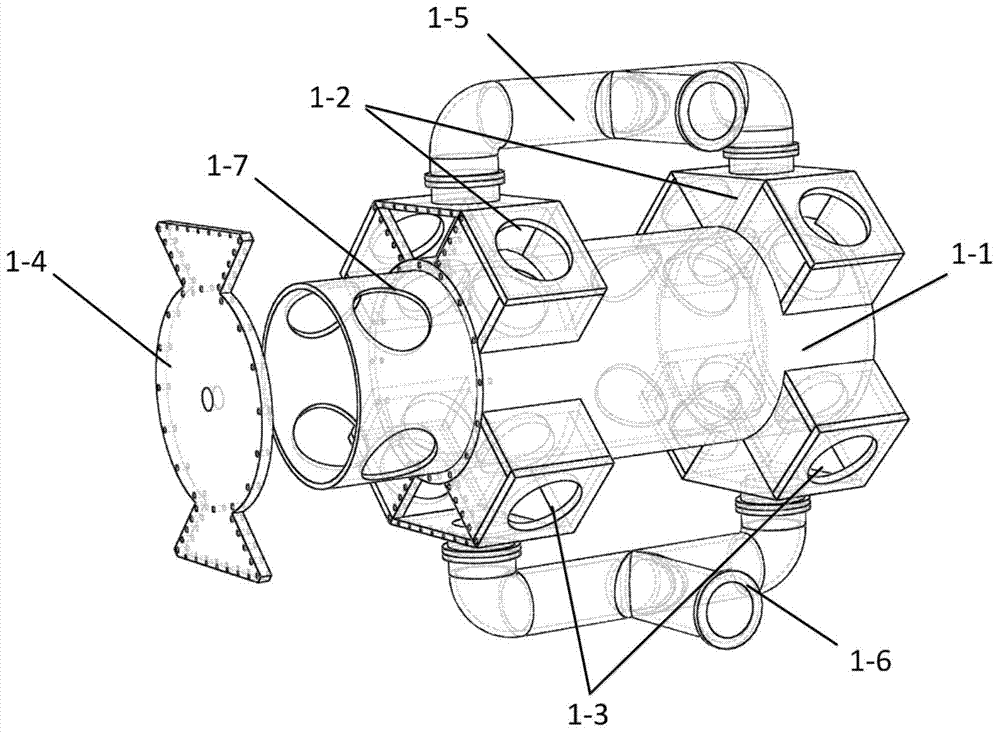

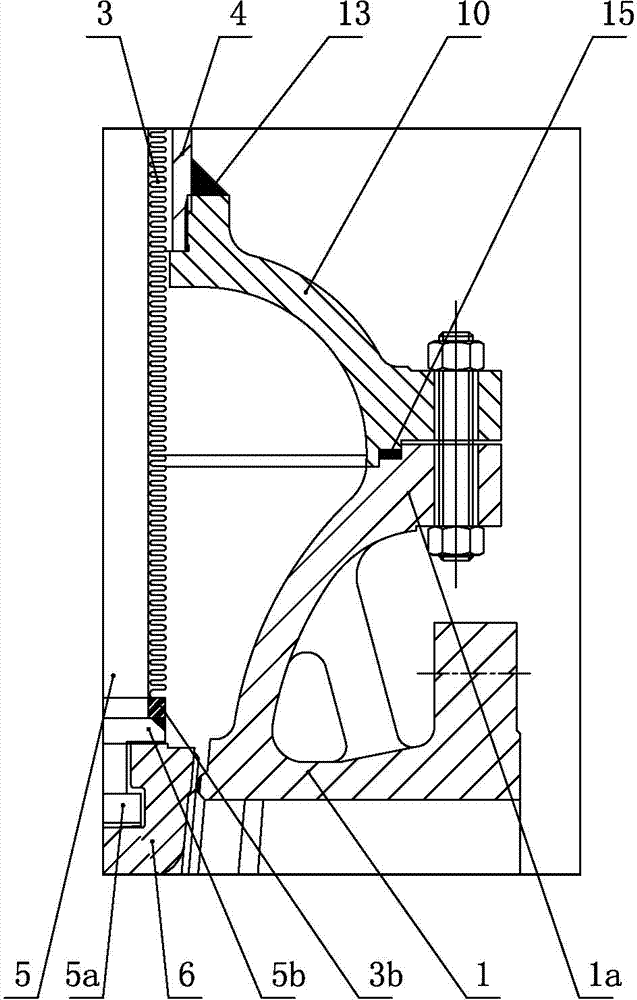

The invention relates to a small-sized five-axis machining center which comprises a base structure (1), an XYZ vertical shaft structure (2) and a BC rotary table (3). The small-size five-axis machining center is characterized in that the base structure (1) is L-shaped and comprises an X-axis substrate (1-2) and an internally hollow machine tool base (1-1); the X-axis substrate (1-2) is arranged on the machine tool base (1-1) and the X-axis substrate and the machine tool base are of integral structures or fixation connection molding structures; an X-axis ball screw (1-3), a Y-axis ball screw (2-6), a Z-axis ball screw (2-4), two X-axis guide tracks (1-4), two Y-axis guide tracks (2-7) and two Z-axis guide tracks (2-5) are arranged on the X-axis substrate (1-2); the BC rotary table (3) is arranged on a table plate of the machine tool base (1-1) and is arranged beside the positive plane of the X-axis substrate (1-2); a funnel-shaped structure chip discharge port (1-5) is arranged on the table plane of the machine tool base (1-1); and a connecting hole (1-6) of the BC rotary table (3) is arranged at the positive plane of the X-axis substrate (1-2). The small-sized five-axis machining center has the characteristics of being convenient to operate, high in production efficiency, low in cost and attractive and harmonious.

Owner:广州市技师学院

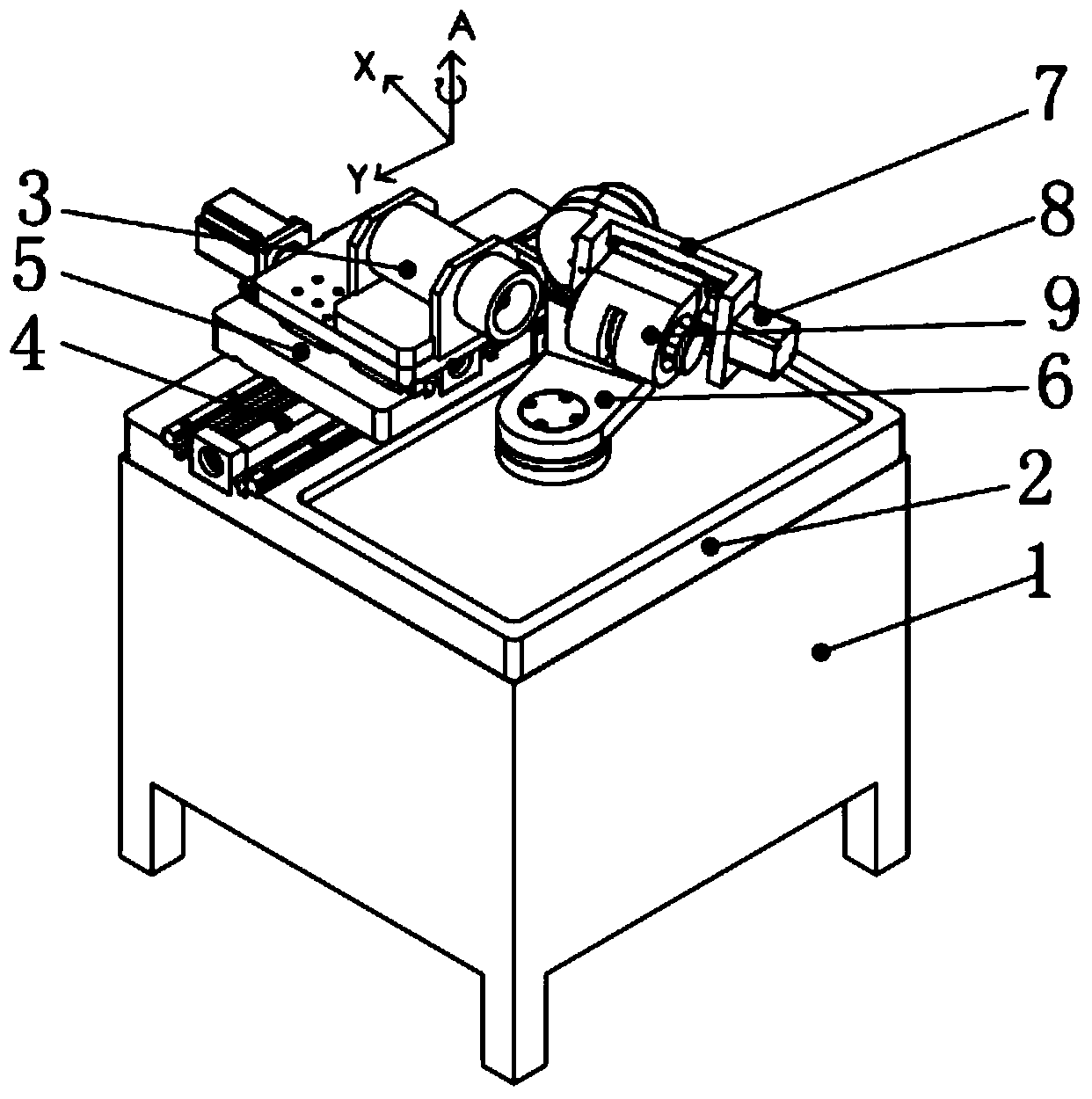

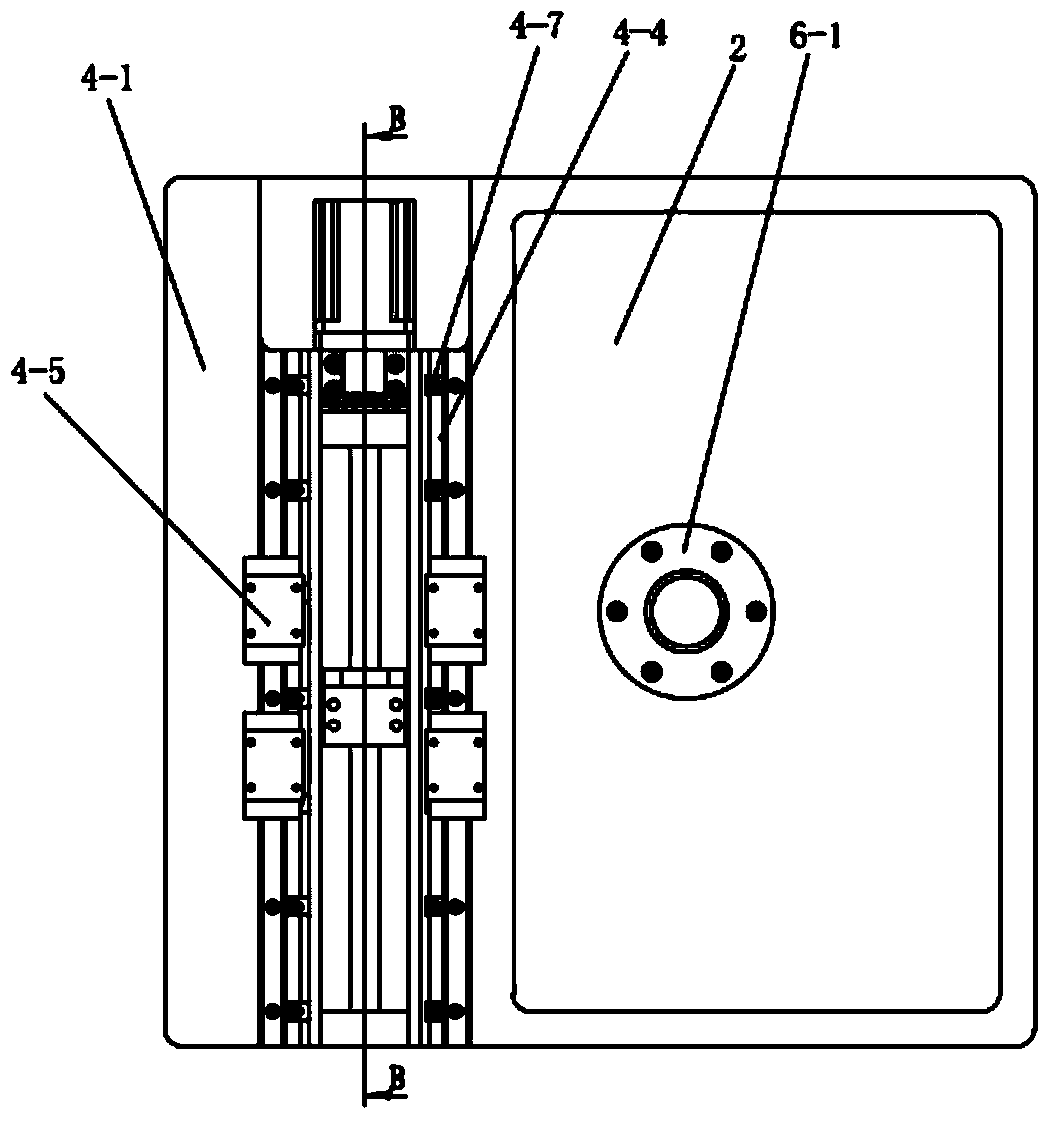

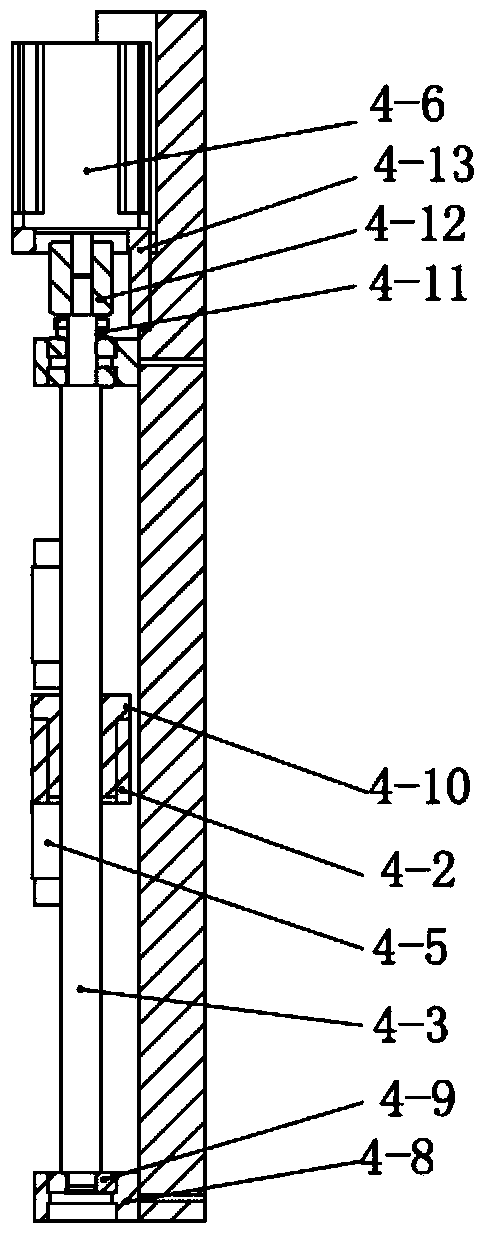

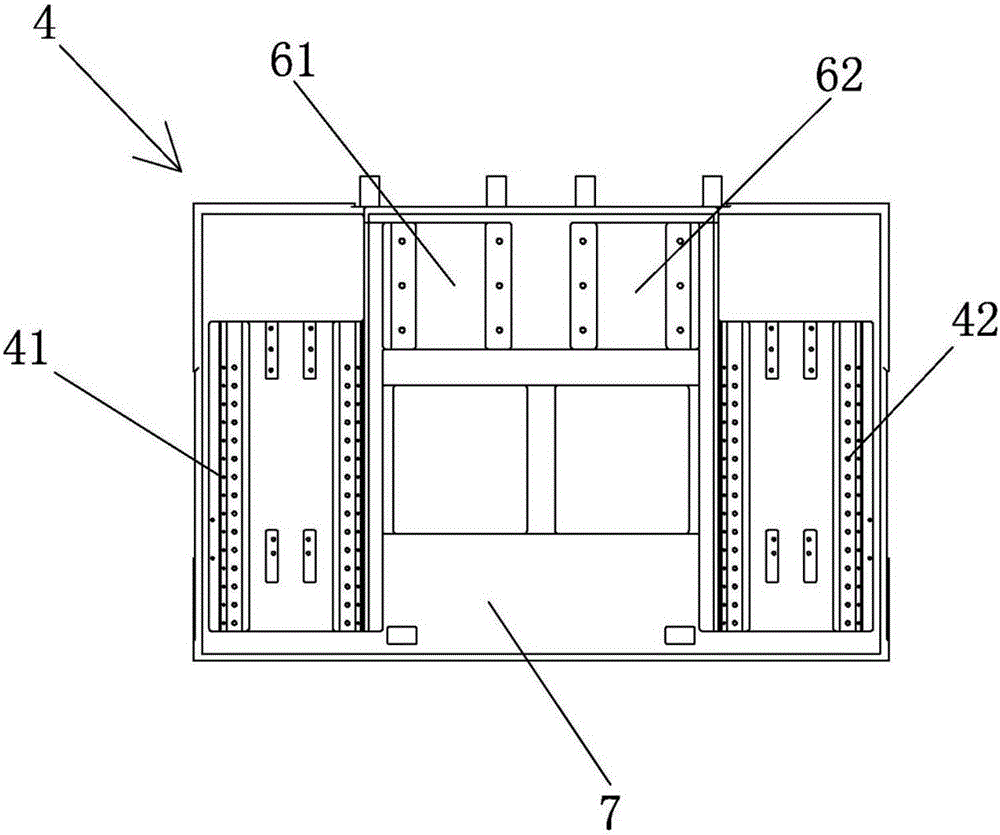

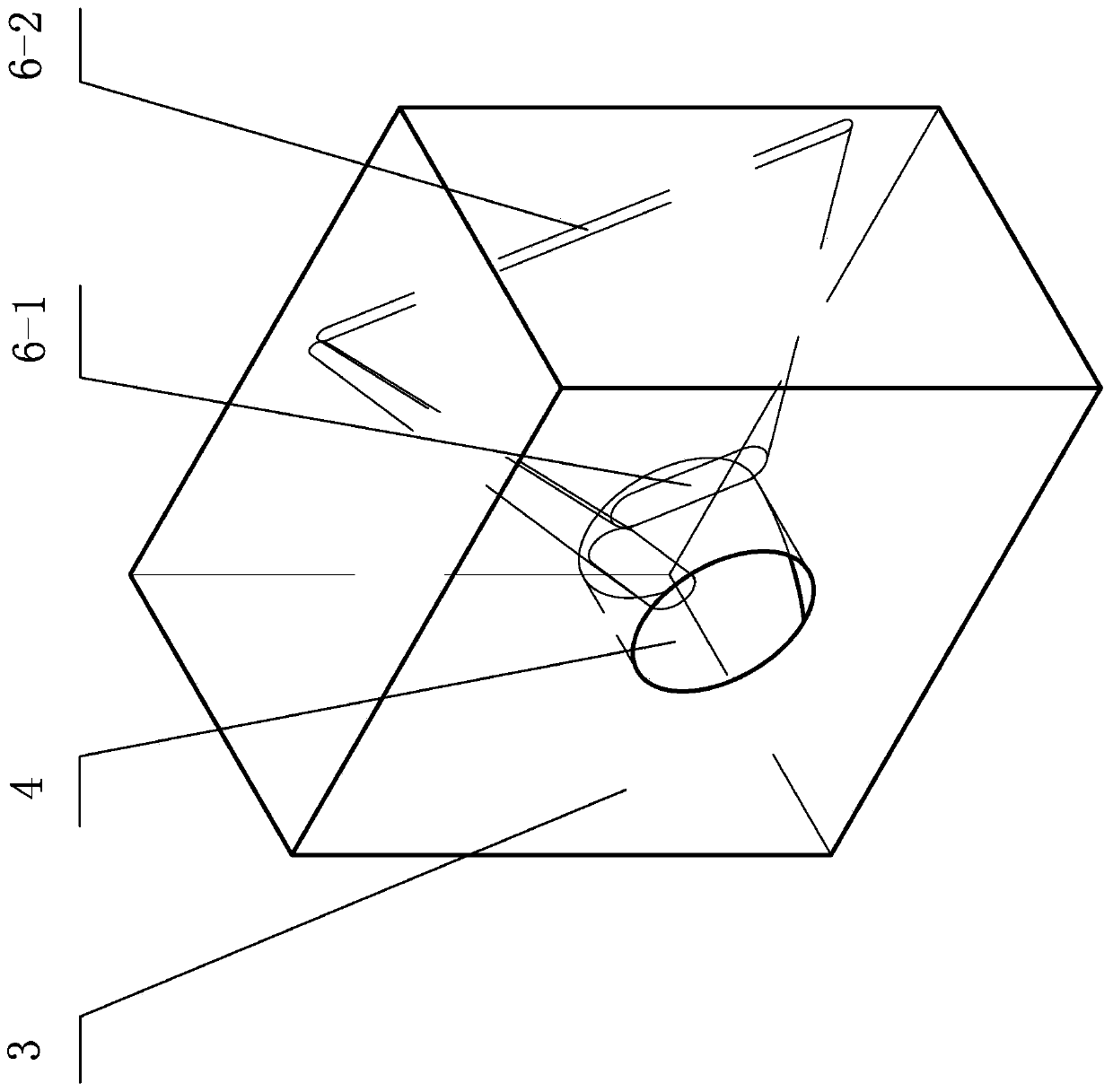

Small-sized six-axis linkage knife grinding device

InactiveCN103586745ARich varietyReduce volumeGrinding drivesOther manufacturing equipments/toolsEngineeringMachining

The invention relates to a small-sized six-axis linkage knife grinding device which is characterized by comprising a small-sized rack, a device body, a knife grinder and a six-axis linkage mechanism. The six-axis linkage mechanism is composed of a Y-axis moving mechanism, an X-axis moving mechanism, a Z-axis moving mechanism, an A-axis rotating mechanism, a B-axis rotating mechanism and a C-axis rotating mechanism. The knife grinder is driven by the X-axis moving mechanism and the Y-axis moving mechanism to perform linear movement, the movement trail of the Y-axis moving mechanism is perpendicular to the movement trail of the X-axis moving mechanism, and a knife installation unit is arranged on the C-axis rotating mechanism. The Z-axis moving mechanism is driven by the B-axis rotating mechanism to rotate around the B axis, the C-axis rotating mechanism is driven by the Z-axis moving mechanism to move front and back along the Z axis, the knife installation unit is driven by the C-axis rotating mechanism to rotate around the C axis, and the small-sized six-axis linkage knife grinding device is accordingly formed. The small-sized six-axis linkage knife grinding device has the advantages of being simple in structure, small in size, light in weight, multiple in grinded knife variety, wide in application range, capable of being used for small-sized machining production and capable of being used for teaching.

Owner:广州市技师学院

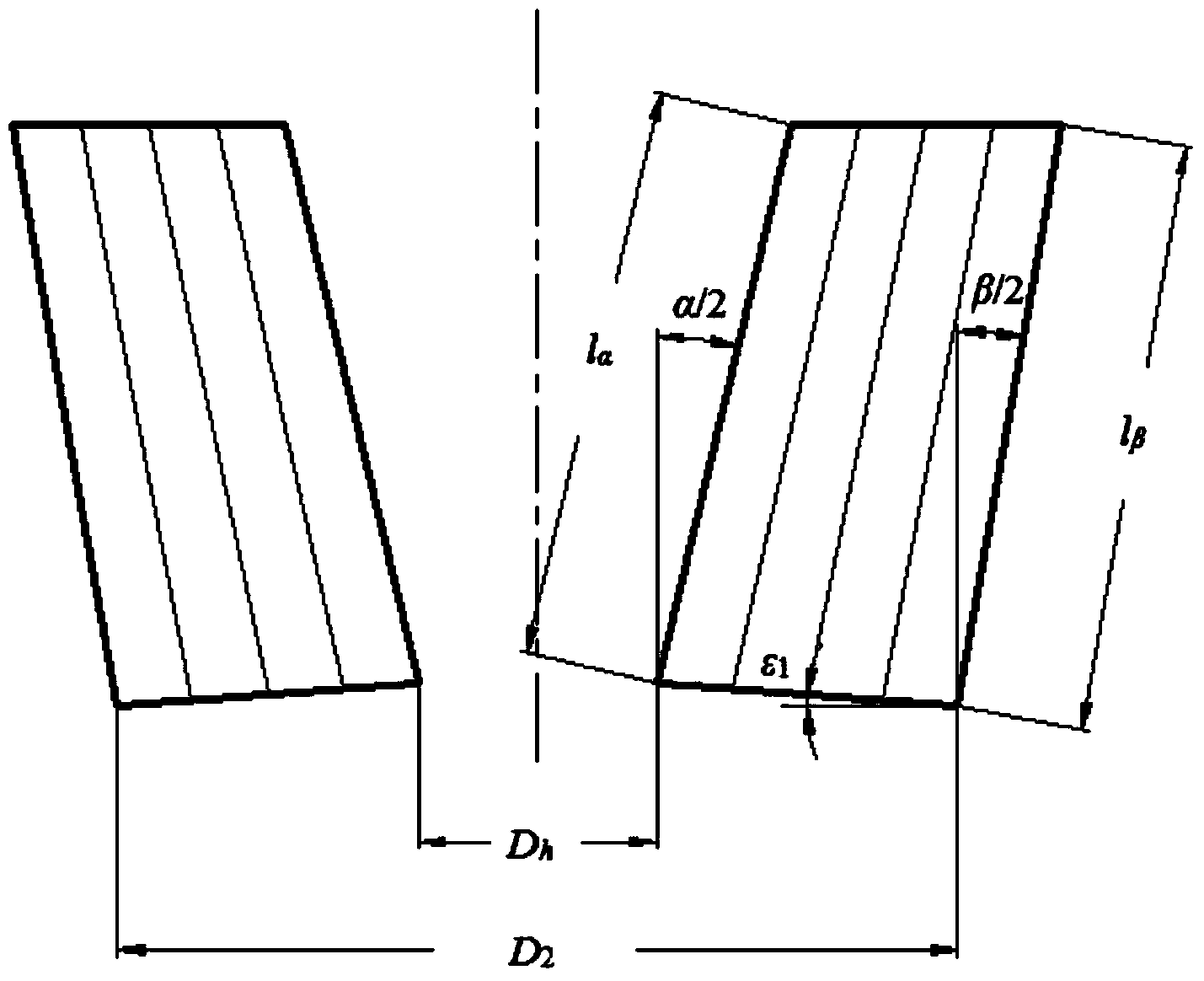

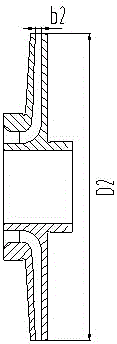

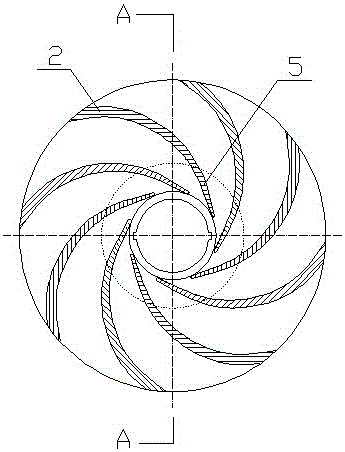

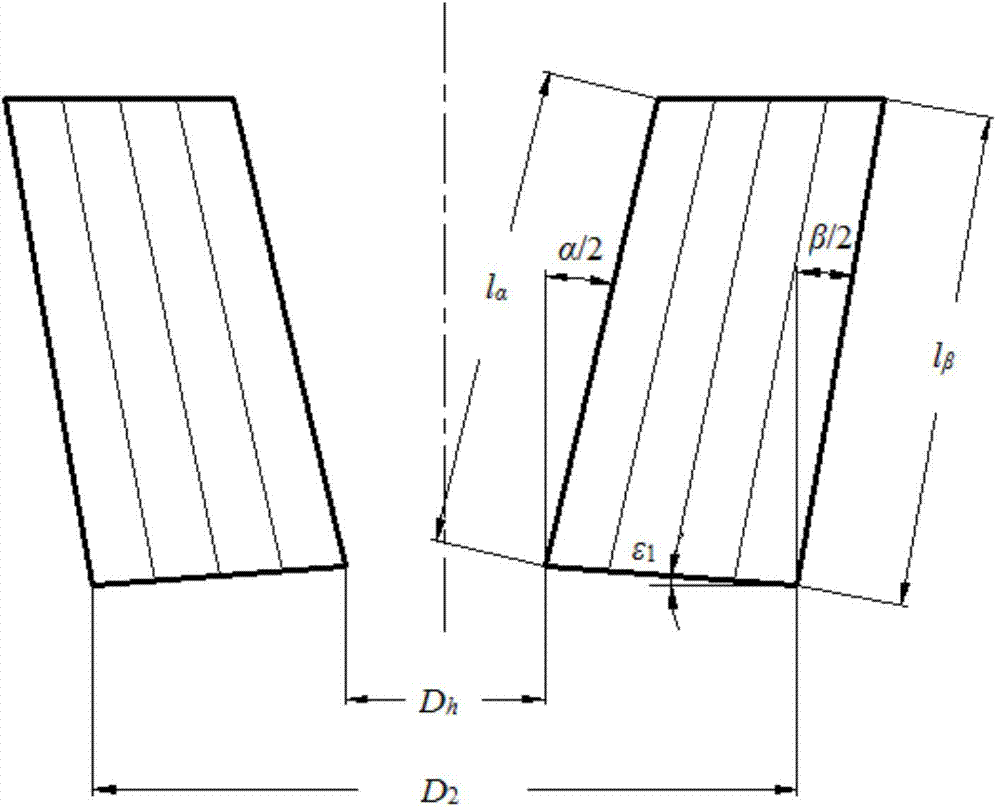

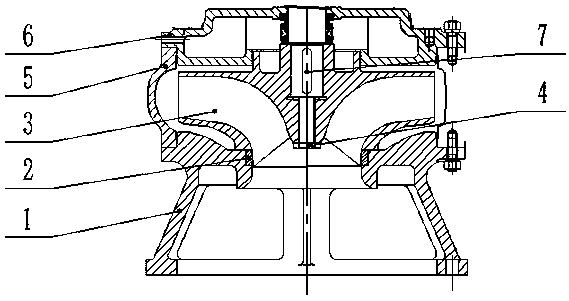

Method for designing submersible axial-flow pump guide vane and submersible axial-flow pump guide vane

ActiveCN103644140AImprove operational reliabilityHigh strengthPump componentsPumpsAxial-flow pumpImpeller

The invention provides a method for designing a submersible axial-flow pump guide vane and a submersible axial-flow pump guide vane. According to the method, the entry guide vane hub diameter Dh, the entry guide vane outer diameter D2, the guide vane entry inclination angle epsilon1, the guide vane inner side divergence angle alpha, the guide vane outer side divergence angle beta, the guide vane inner flow line length alpha1 and the guide vane outer flow line length beta1 of the submersible axial-flow pump guide vane are determined on the basis of the hub diameter and the guide vane outer diameter of a submersible axial-flow pump guide vane wheel. Design can be rapidly achieved, manpower is saved, and the performance curve of the submersible axial-flow pump guide vane coincides with a required performance curve. Compared with a traditional design method for a submersible axial-flow pump guide vane, lift and efficiency are improved, ranges of efficient areas are widened, and operational reliability of the submersible axial-flow pump guide vane is improved.

Owner:JIANGSU KAIQUAN PUMP IND MFG

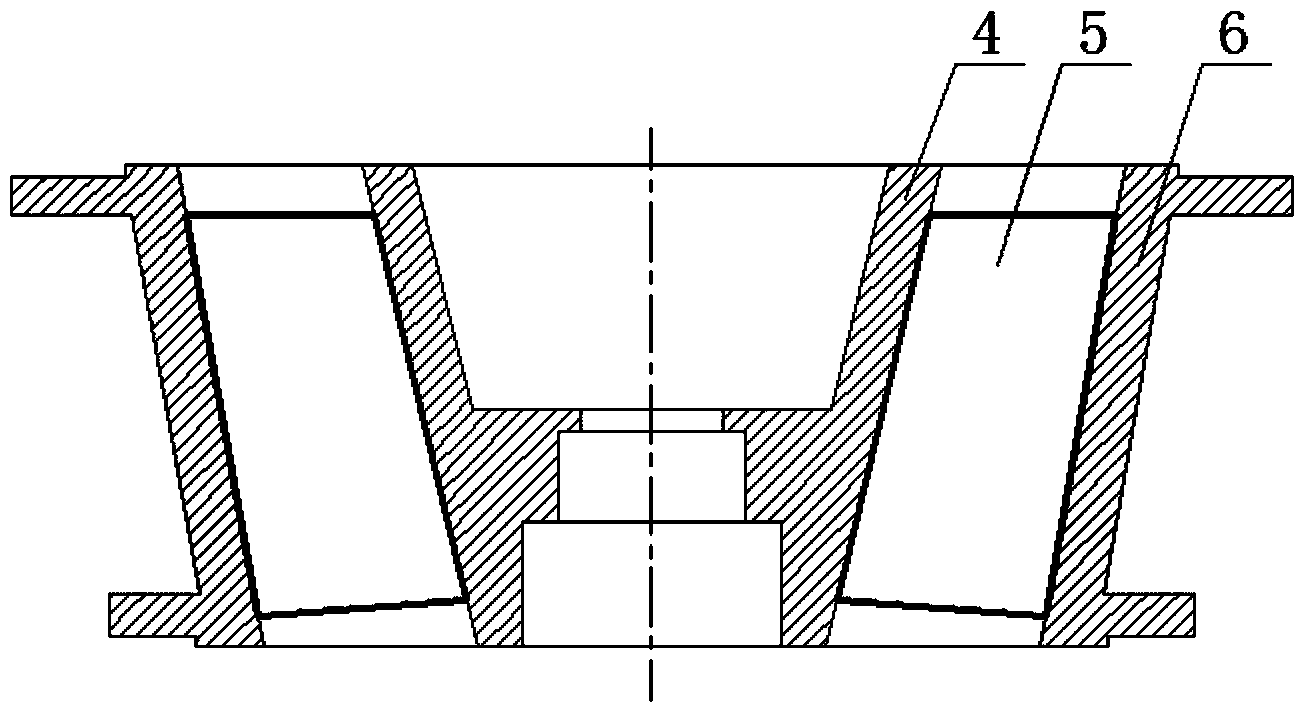

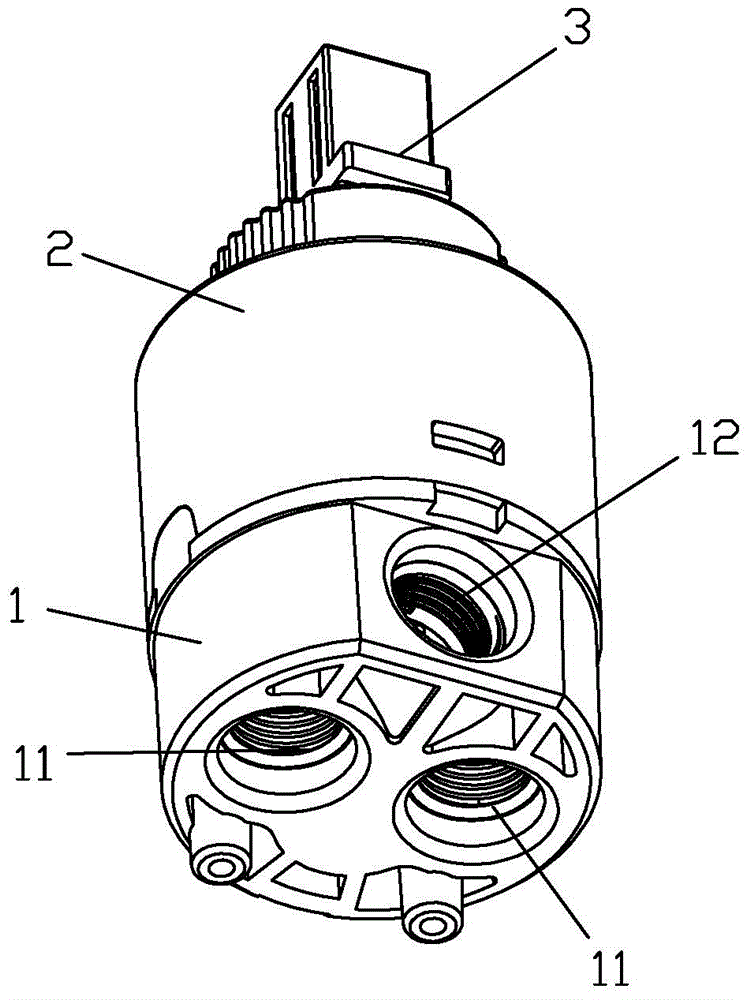

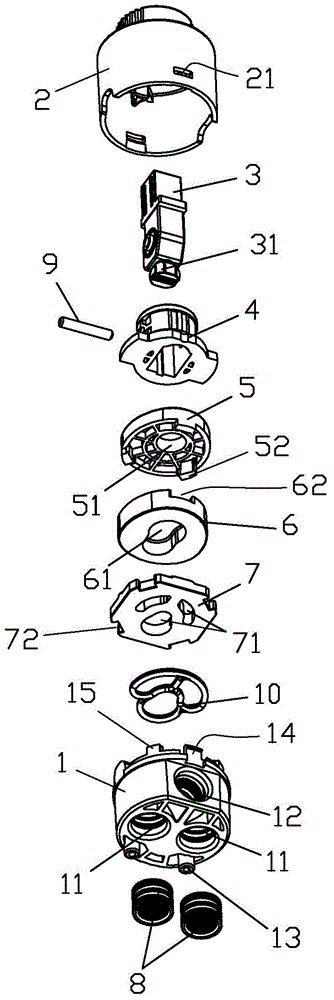

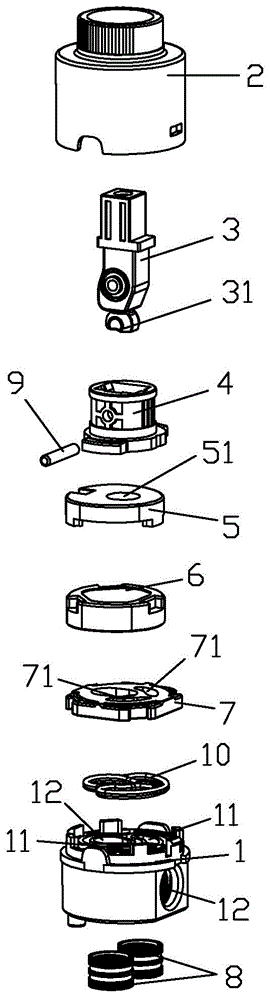

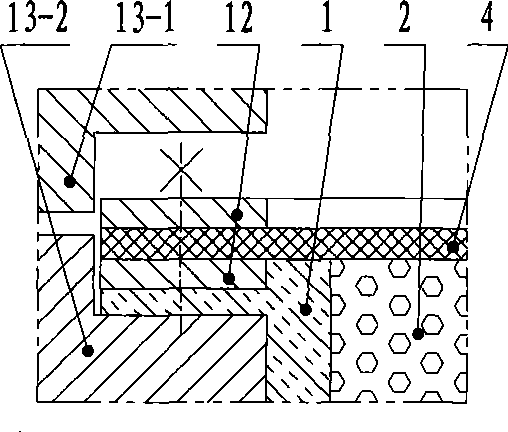

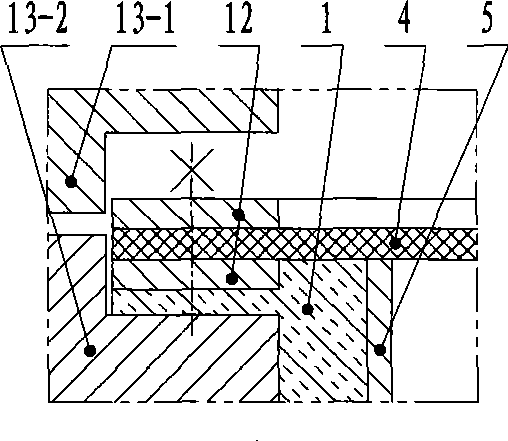

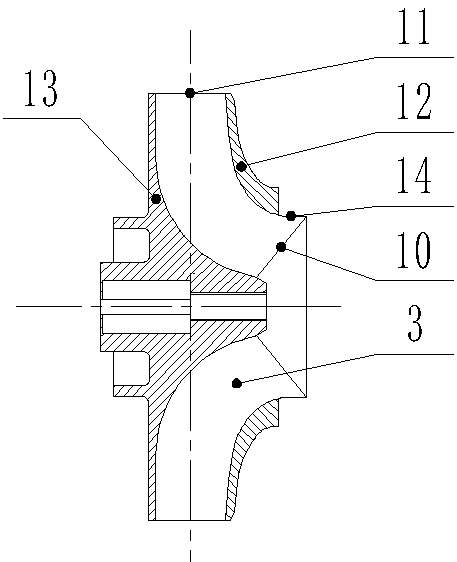

Poking rod control type valve core

InactiveCN104565414AReduce material requirementsThe main structure is simpleSlide valveWater flowScrew thread

The invention discloses a poking rod control type valve core. The poking rod control type valve core comprises a base and a valve body, wherein a poking rod, a support, a poking disc, a ceramic rotor plate and a ceramic stator plate are sequentially arranged in the valve body from top to bottom, a containing hole is formed in the poking disc, the ceramic rotor plate is fixedly connected with the poking disc, the ceramic stator plate is fixed on the base, the bottom end surface of the base is provided with two water inlet passages which axially penetrate through the base, the side wall of the base is provided with a water outlet passage which stretches to the upper end surface of the base, water holes which correspond to the water inlet passages and the water outlet passage are formed in the ceramic stator plate, and a concave cavity which corresponds to the water holes in the ceramic stator plate is formed in the ceramic rotor plate; the poking rod is connected to the support in a pivoting way, the lower end of the poking rod stretches into the containing hole of the poking disc, the ceramic rotor plate is driven to move through the poking disc by the poking rod, and communicating or opening and closing states between the concave cavity in the ceramic rotor plate and the water holes can be realized; water inlet pipe connectors which are provided with threads are embedded into the water inlet passages, and the water outlet passage is a plastic threaded hole which is connected with a standard hose, so that water flow cannot pass through a faucet main body, and the requirement on the faucet main body is low.

Owner:GUANGDONG HENT TECH

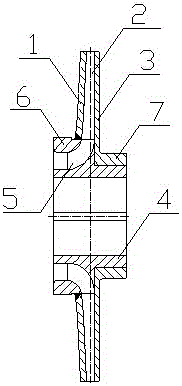

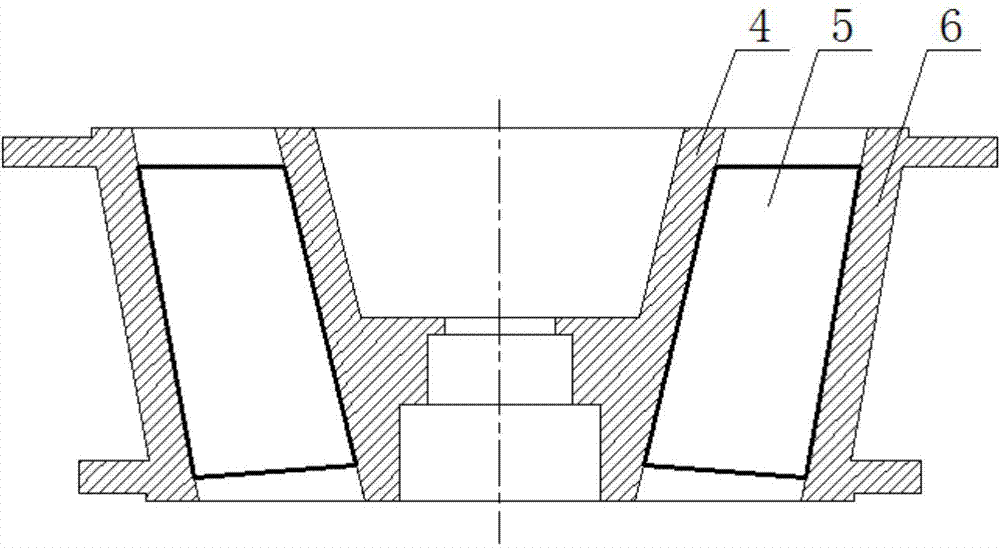

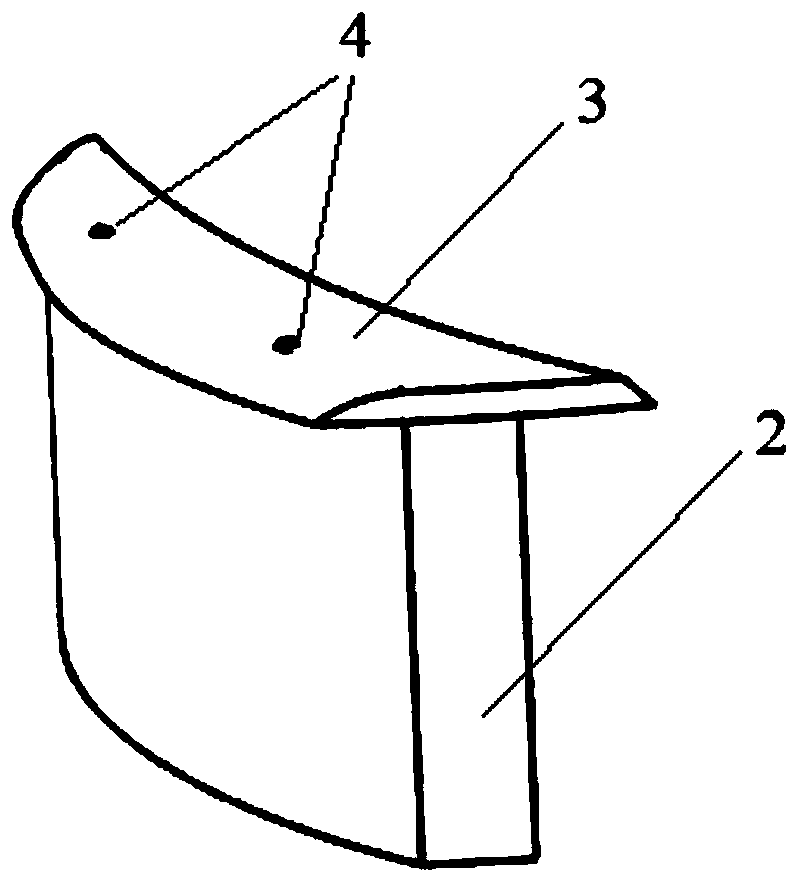

Low-specific-speed impeller structure and machining method thereof

The invention discloses a low-specific-speed impeller structure and a machining method thereof. The structure comprises an impeller body part and an impeller root part; the impeller body part includes a front cover plate, a blade body part and a back cover plate; the impeller root part includes a hub, a blade root part and a sealing ring part; the middle part of the back cover plate is downwards projected to form a sleeve; the back cover plate coats the back part of the hub through the sleeve; the front cover plate coats the sealing ring part; an annular welding line is formed between the front cover plate and the sealing ring part; and the front cover plate and the sealing ring part are tightly welded through the annular welding line. The machining method comprises the following steps: 1) the impeller body part and the impeller root part are respectively cast; 2) the impeller body part coats the impeller root part from the back end of the impeller root part; and the front cover plate coats the sealing ring part; and 3) the annular welding line between the front cover plate and the sealing ring part is tightly welded. The structure is low in machining difficulty, high in machining precision and better in total quality, improves the machining yield, is high in impeller stability, and can effectively improve the guide efficiency.

Owner:重庆水泵厂有限责任公司

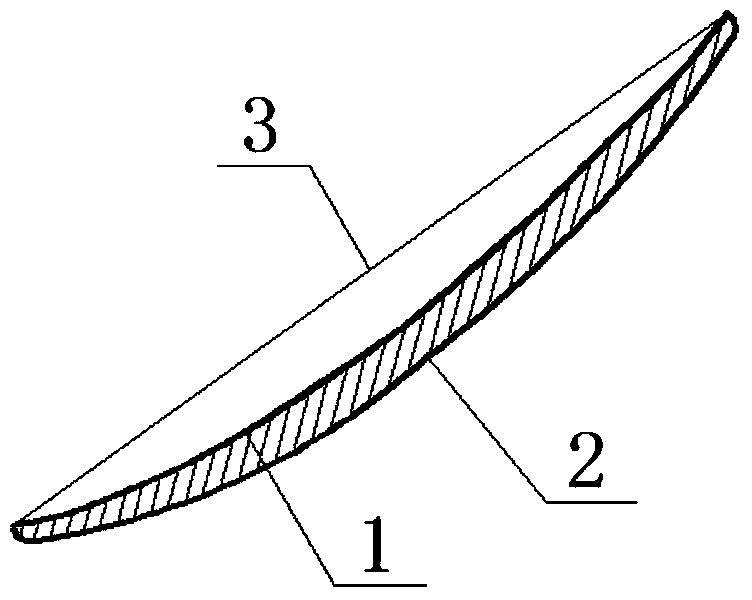

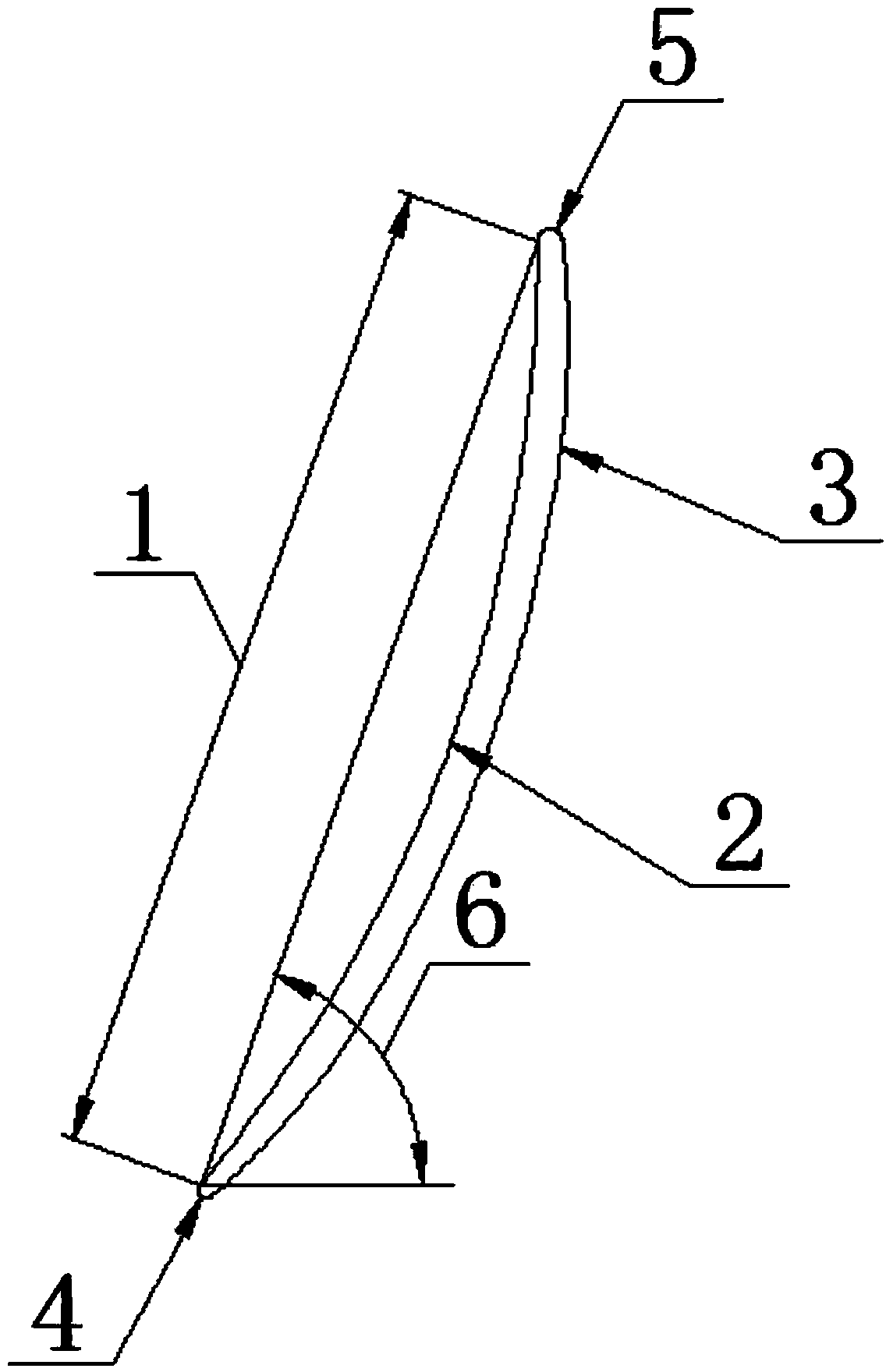

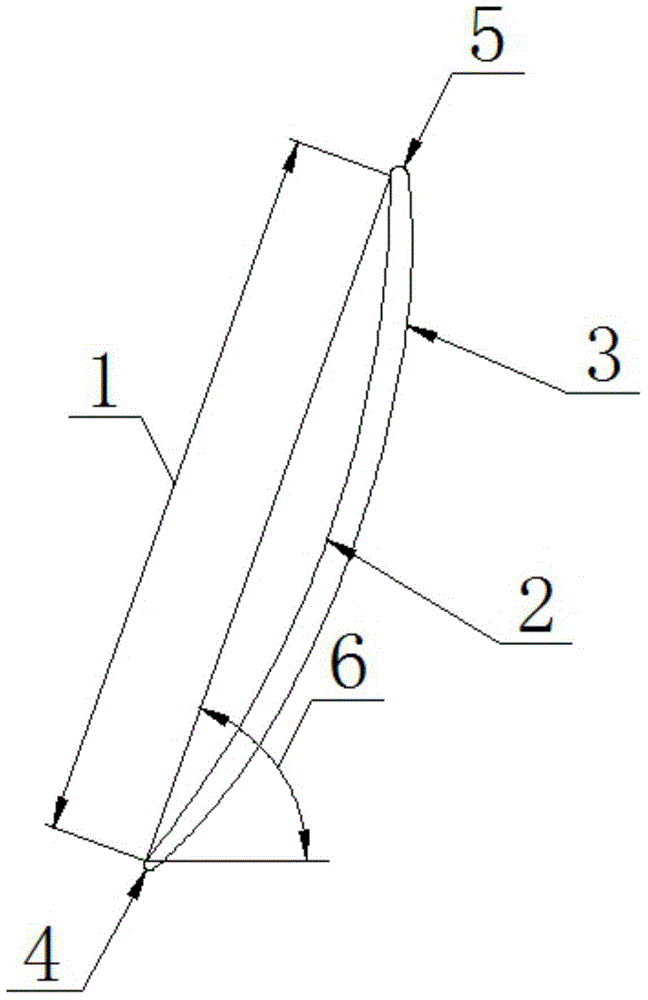

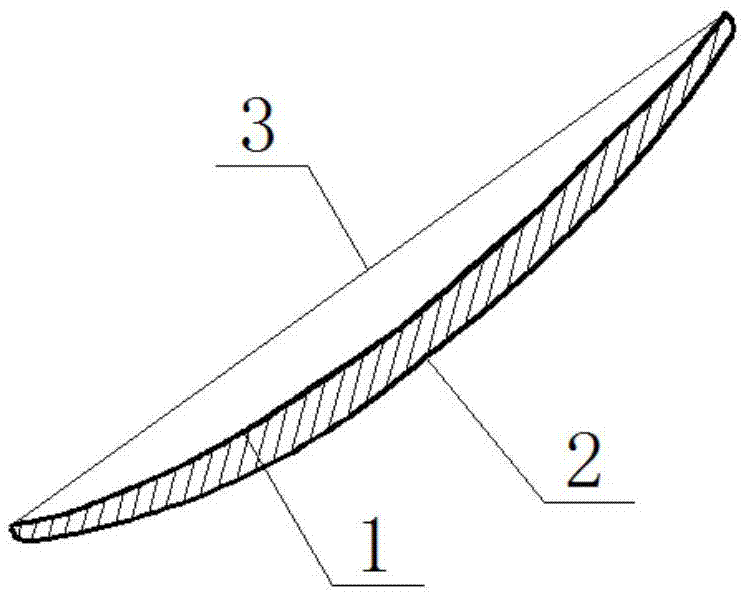

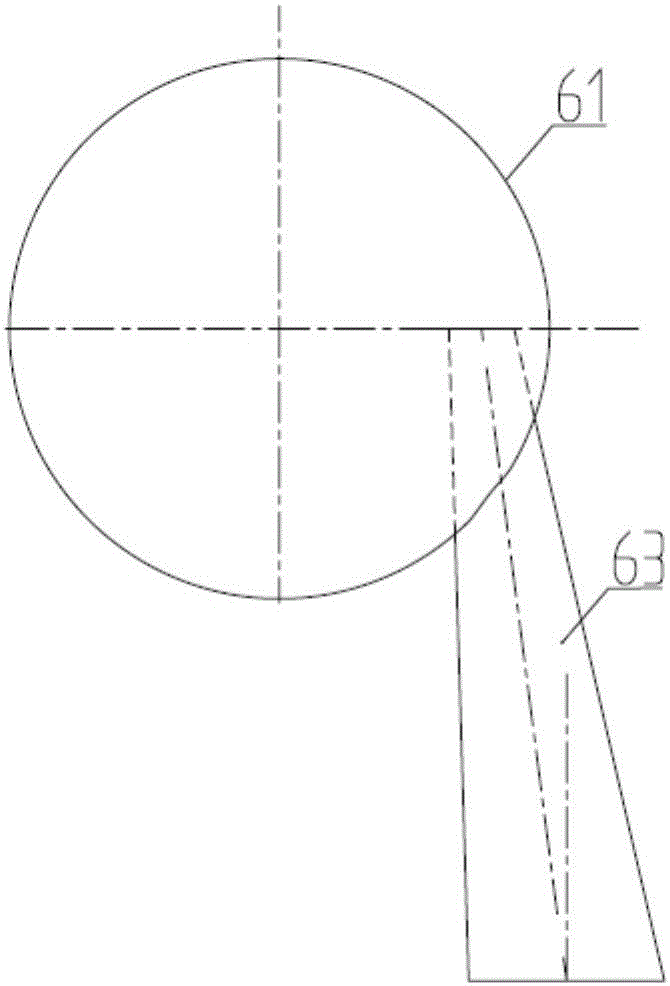

Axial pump vane airfoil optimizing design method

ActiveCN103557185AHigh strengthExtended service lifePump componentsPumpsAxial-flow pumpStructural engineering

The invention relates to an improvement of a traditional axial pump vane airfoil design method, and provides a novel axial pump vane airfoil optimizing design method. The method has the advantages that the strength of a vane is effectively improved, the service life of the vane is prolonged, the casting difficulty of the vane is reduced, the vane drawing time is greatly shortened, the labor is saved, and the hydraulic performance of the vane is ensured. The method is characterized in that the sharp parts at the inlet and outlet ends of the back surface of the vane airfoil are changed into the circular arc transition, and the parts near the inlet and outlet ends are properly thickened; the placing position of the vane is determined by using the profile placing angle to replace the vane inlet and outlet placing angle; the vane airfoil is designed according to the following main parameters, namely chord length l, working surface profile radius R1, back surface profile radius R2, vane inlet circular arc radius r1, vane outlet circular arc radius r2, and profile placing angle alpha L.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

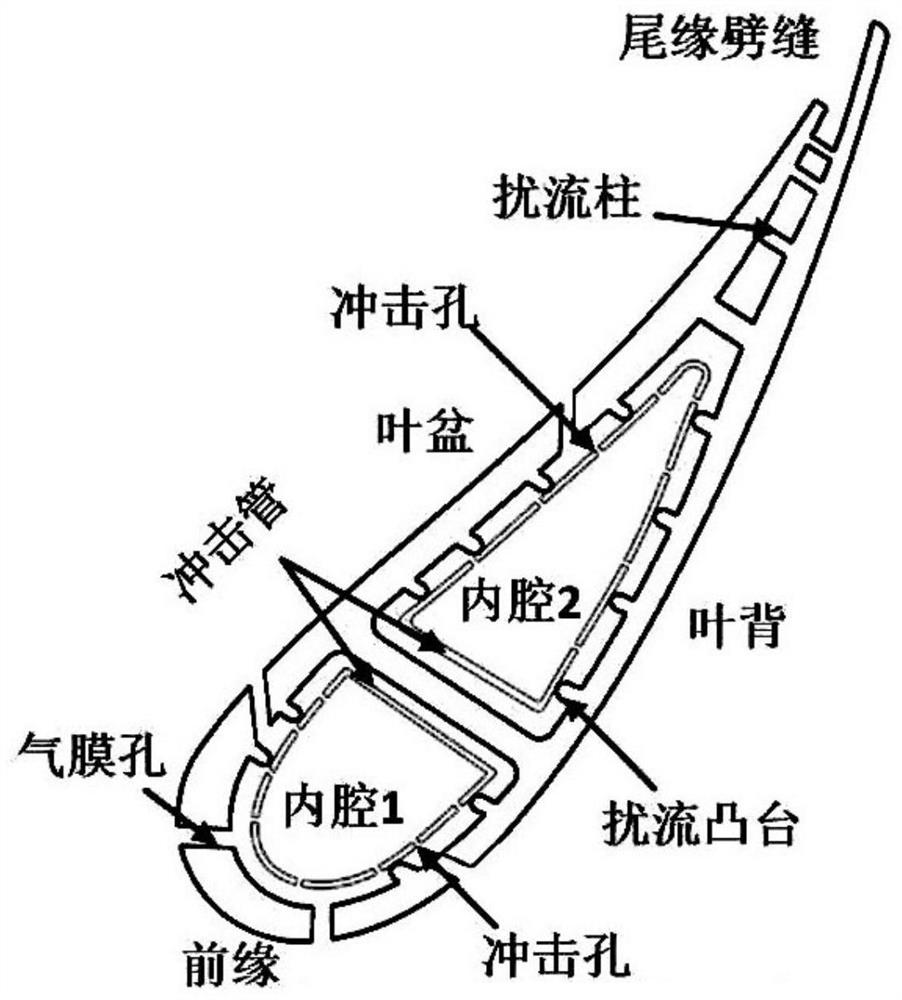

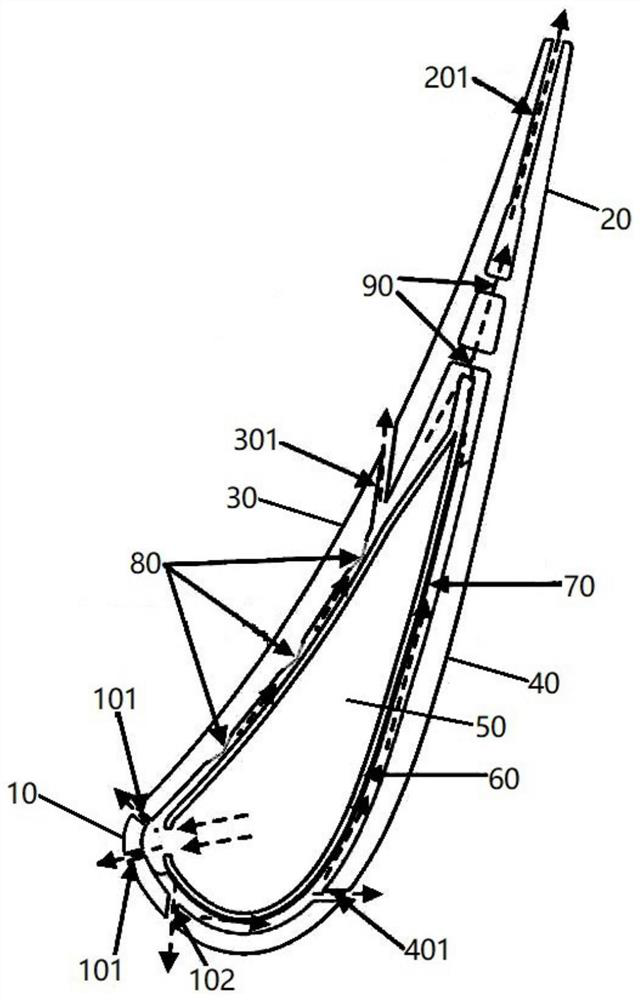

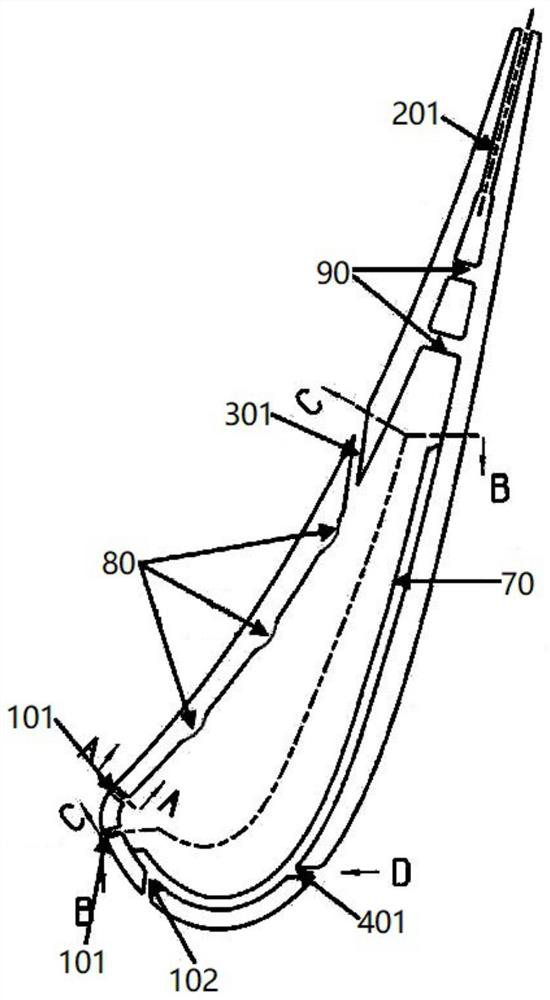

Gas turbine guide vane

ActiveCN113374536AReduce casting difficultyReduce lossesEfficient propulsion technologiesStatorsCold airJet flow

The invention discloses a gas turbine guide vane. The gas turbine guide vane comprises a vane body, a single inner cavity is further formed in the vane body, an impact pipe communicating with a cold air loop is installed in the inner cavity, a jet flow slit penetrating through the front edge of the impact pipe is formed in the front edge of the impact pipe, and the jet flow slit is used for allowing cold airflow in the inner cavity to penetrate through and then conducting jet flow impact cooling on the inner wall face of the blade-shaped front edge. The outer wall face of the blade-shaped front edge is further provided with a plurality of crossed air film hole sets penetrating through the blade-shaped front edge, first air film holes in the crossed air film hole sets are perpendicular to the outer wall face of the blade-shaped front edge in the blade-shaped section, and included angles of 30-60 degrees are formed between the first air film holes and the blade-shaped section. According to the gas turbine guide vane, the casting difficulty of the guide vane can be greatly reduced, the cooling effect is better, the temperature field is more uniform, and the diffusion of cold airflow can be reduced, so that under the condition of the same gas amount and cold air amount, the covering effect of a gas film formed by the cold airflow on the outer wall face of the blade-shaped front edge is better, and the cooling effect is better.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

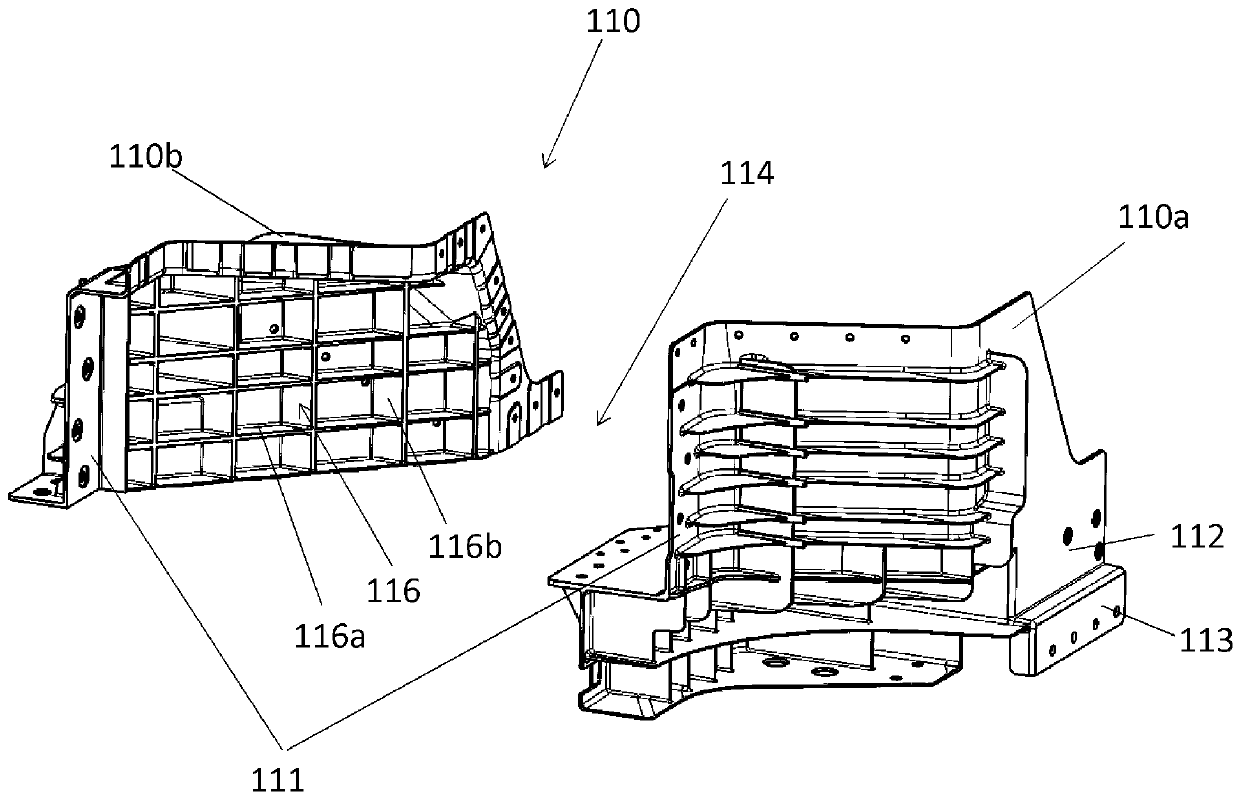

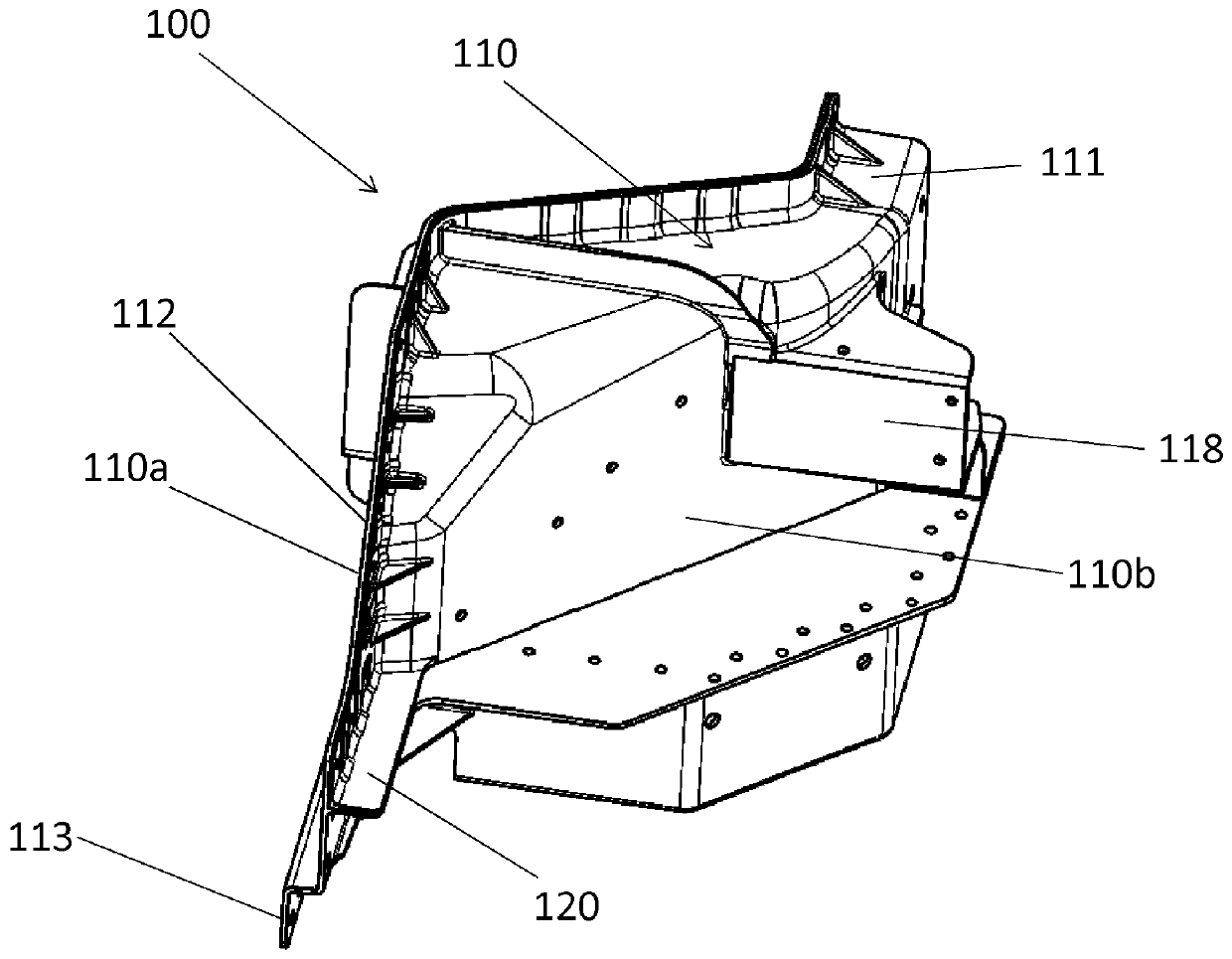

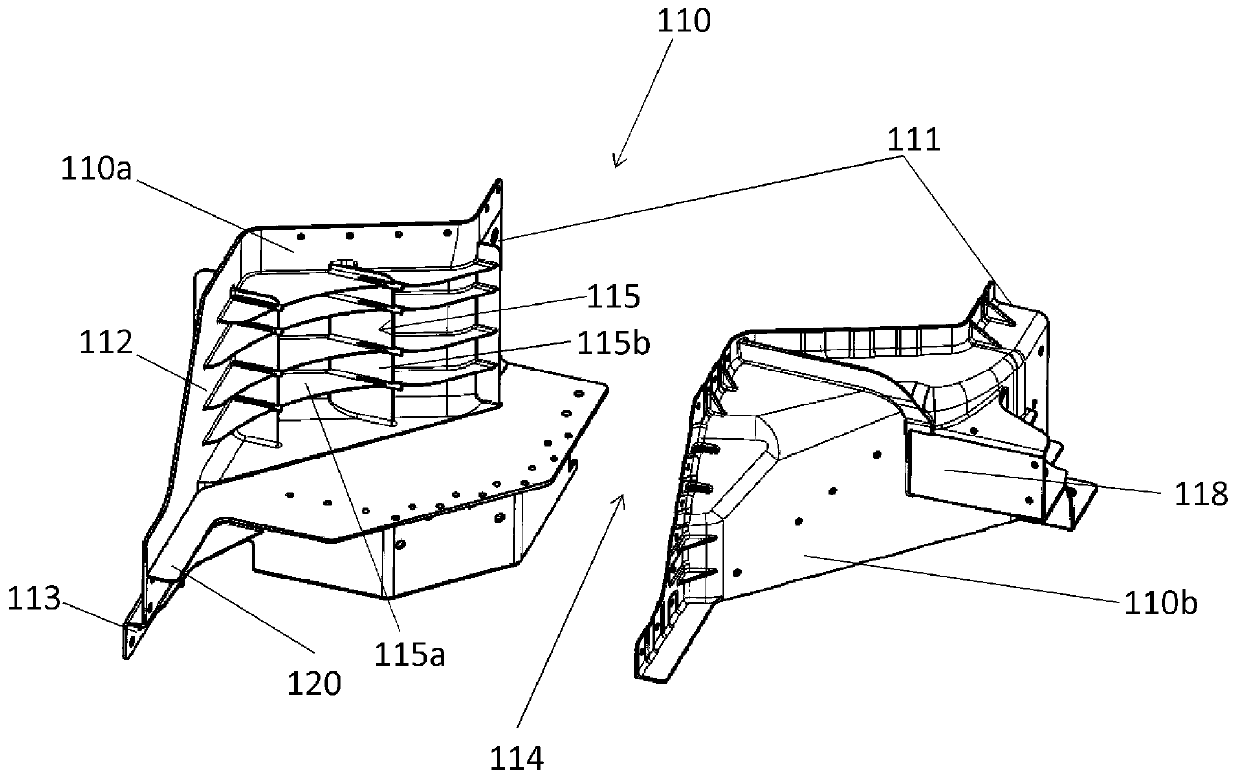

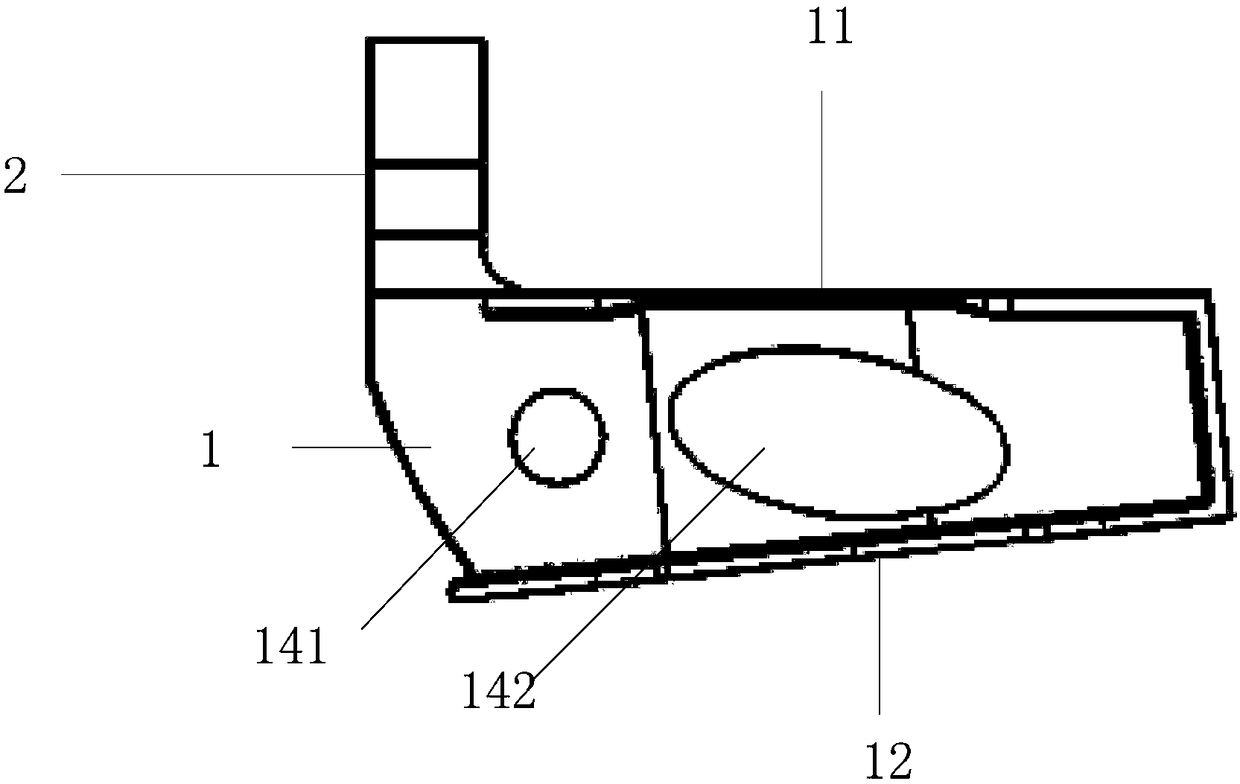

Car frame connecting piece for electric car, car frame assembly and electric car

PendingCN110304146AReduce casting difficultyEasy processing and wide applicationUnderstructuresVehicular energy storageVehicle frameElectric cars

The invention discloses a connecting piece for a car frame, a car frame assembly and an electric car. The car frame connecting piece comprises a connecting piece base. The connecting piece base is atleast provided with a front longitudinal beam connecting part, an A column lower inner plate connecting part and a threshold longitudinal beam connecting part; when orienteering is performed along thecar frame, the front longitudinal beam connecting part is located in the front of the connecting piece base 110, the A column lower inner plate connecting part is located at the outer side of the connecting piece base 110, and the threshold longitudinal beam connecting part is located at the rear part of the connecting piece base 110; the connecting piece base comprises an outer side connecting piece and an inner side connecting piece with transverse orienteering along the car frame. The car frame connecting piece has the low casting difficulty by designing the split structure of the inner side and outer side mode, and the car frame connecting piece is suitable for being widely applied; the connecting strength of a car frame and a key joint is enhanced, and the collision safety performance is improved.

Owner:NIO ANHUI HLDG CO LTD

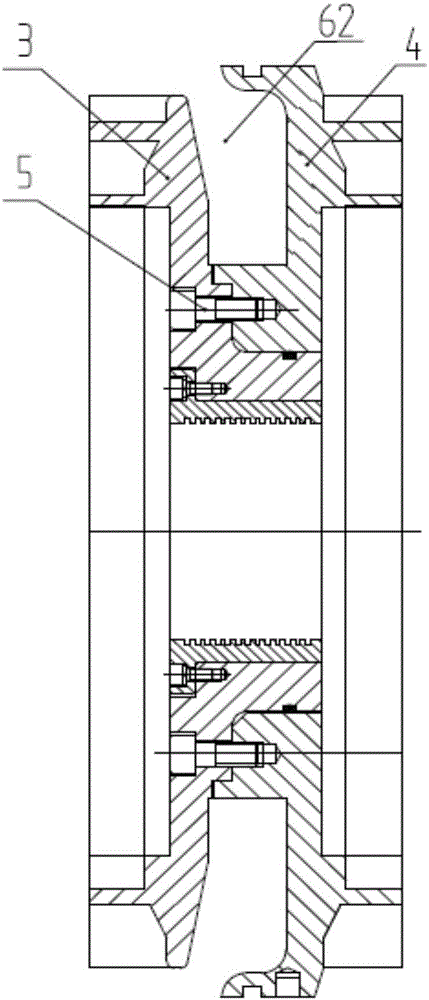

Low-temperature air cylinder working chamber component structure of liquefied natural gas vapor compressor

ActiveCN104747405AAvoid heatingSimple structurePositive displacement pump componentsPumpsExhaust valveEngineering

The invention discloses a low-temperature air cylinder working chamber component structure of a liquefied natural gas vapor compressor. The low-temperature air cylinder working chamber component structure of the liquefied natural gas vapor compressor comprises an air cylinder, a piston and a piston rod. A cylinder body of the air cylinder is of a single-wall cylinder type with two open ends, two air inflow valve cages located at the two ends of the cylinder body are arranged at the upper end of the cylinder body, and two air release valve cages located at the two ends of the cylinder body are arranged at the lower end of the cylinder body. According to the low-temperature air cylinder working chamber component structure of the liquefied natural gas vapor compressor, the air cylinder is of a single wall structure, the structure is simple, and casting is facilitated. The valve cages can be cast and formed together with the air cylinder body, and the valve cages can also be welded to the air cylinder by combining plurality of steel plates in a welding method. Due to the fact that the air cylinder body only has the single wall, heat conducted to an upper air suction part through an exhaust part with high temperature during operating can be reduced, inflowing air is effectively prevented from being heated, and more energy is saved in the compressing process. The outward ends of the air inflow valve cages and the outward ends of the air outflow valve cages are open, a plurality of fastening screw holes are formed, an air cylinder cover also serves as outer walls of the valve cages, bolts are used for fastening, and casting difficulty can be further lowered.

Owner:XI AN JIAOTONG UNIV

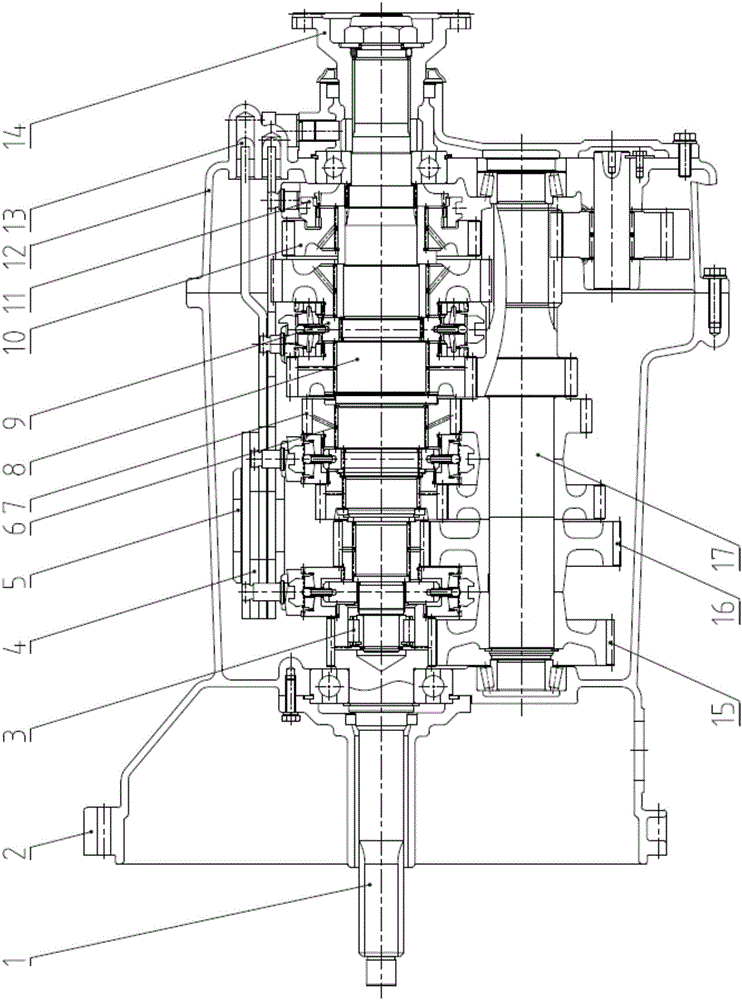

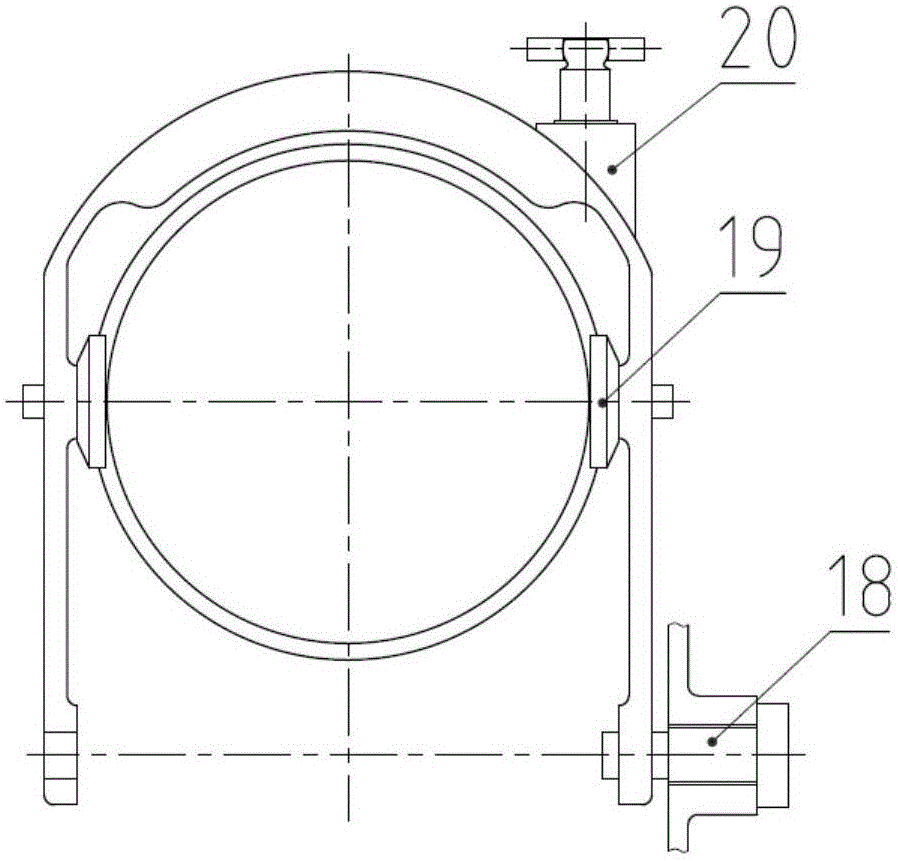

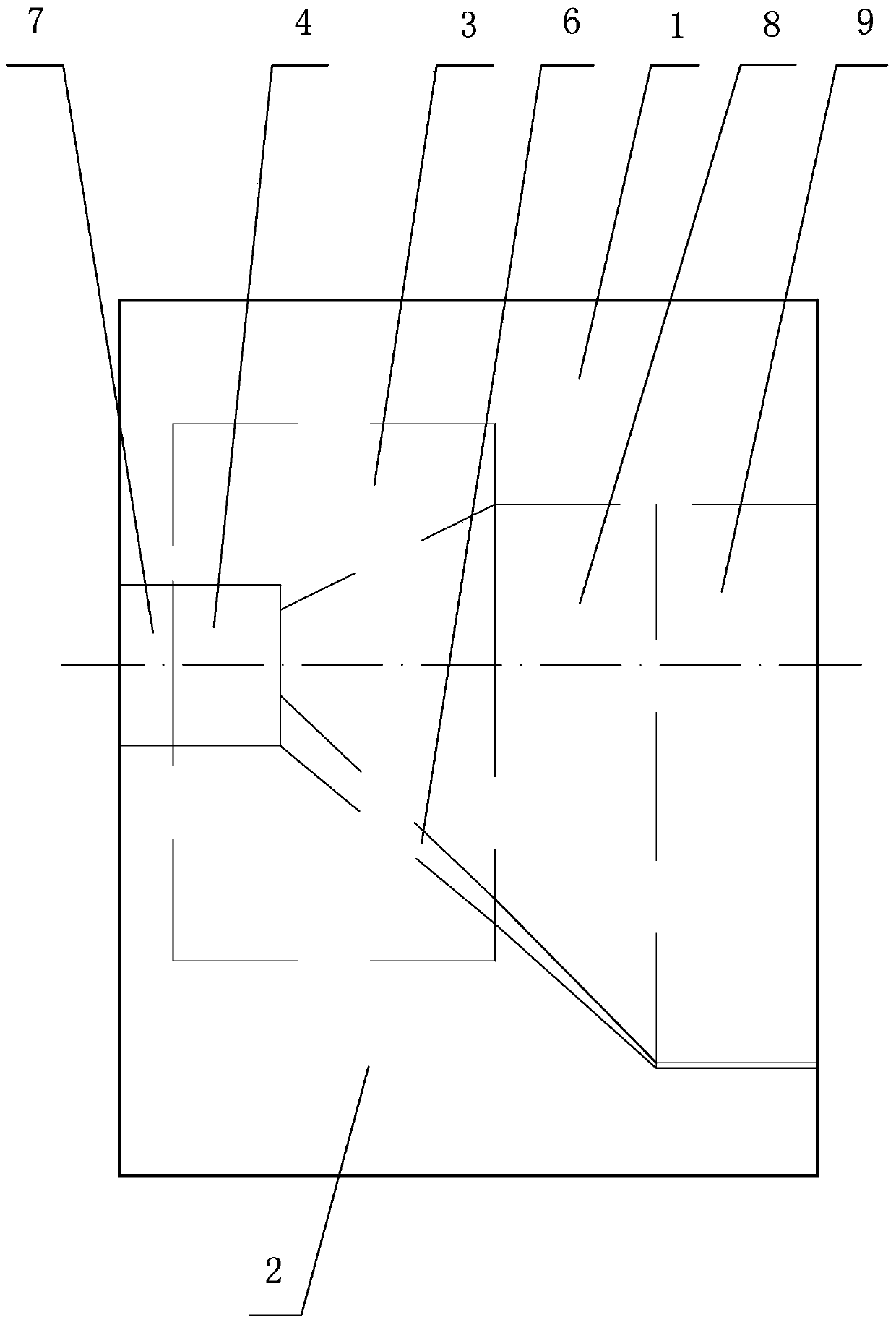

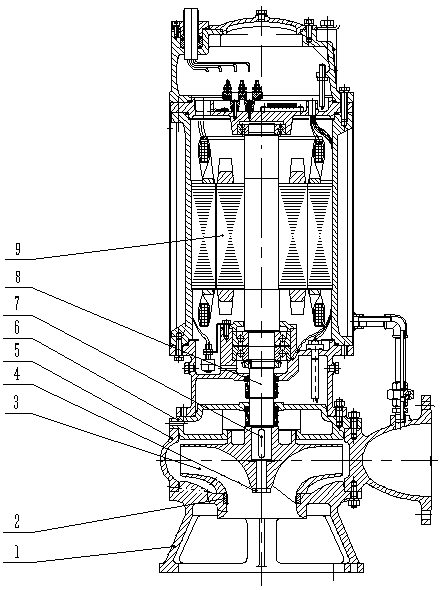

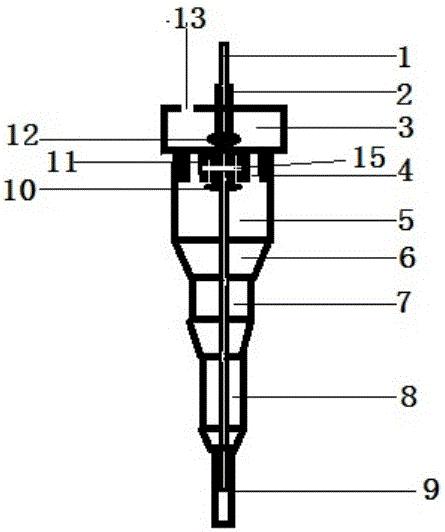

Lubricating device for high-speed bearing in disc separator

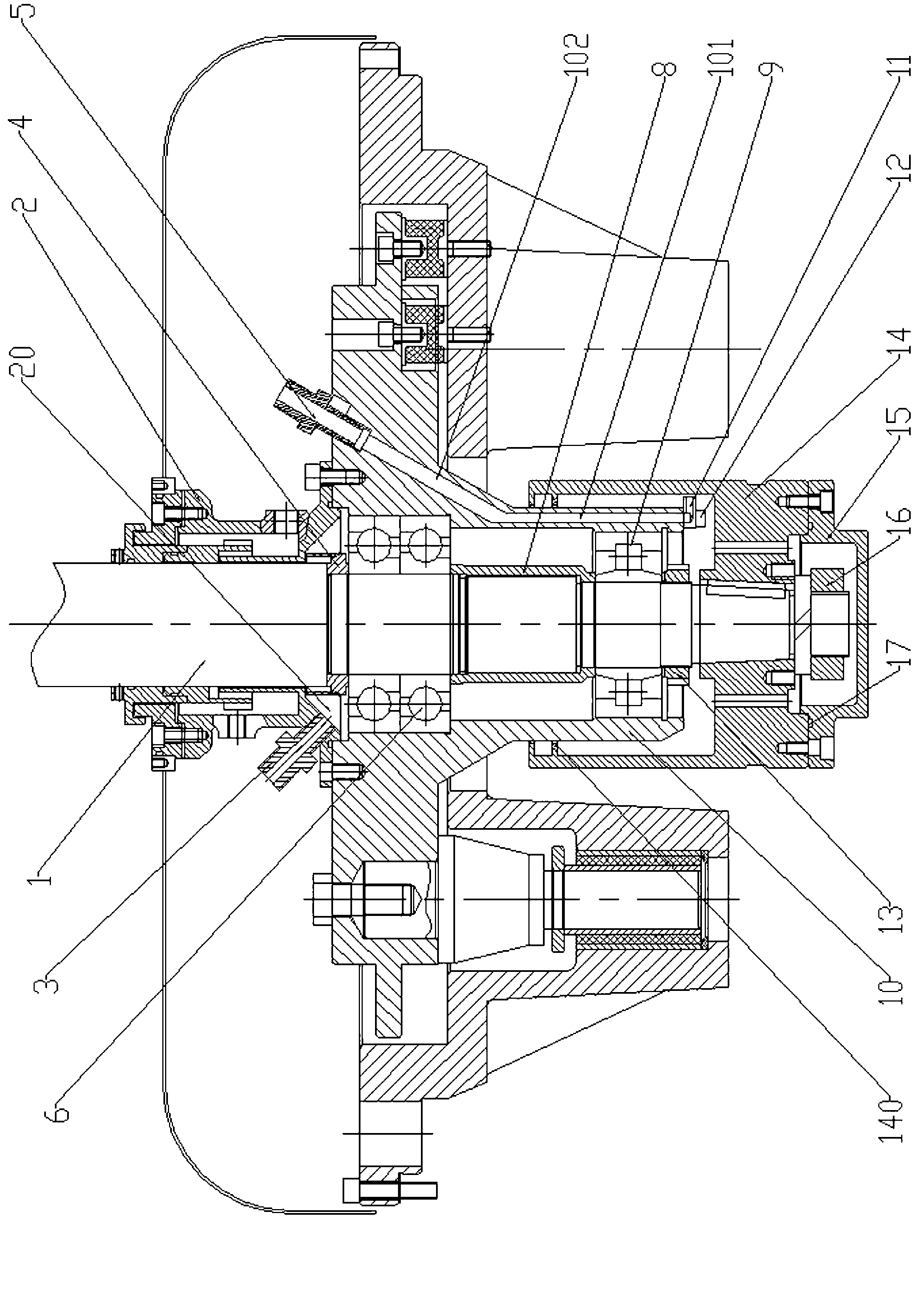

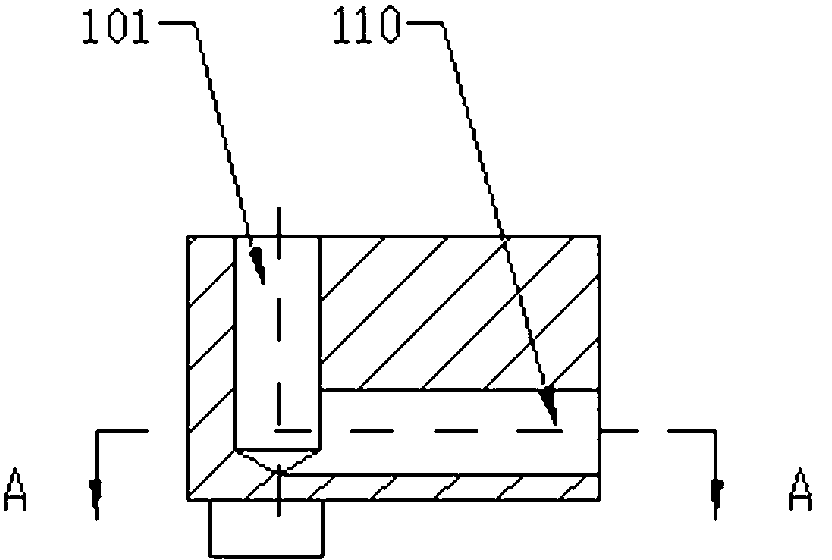

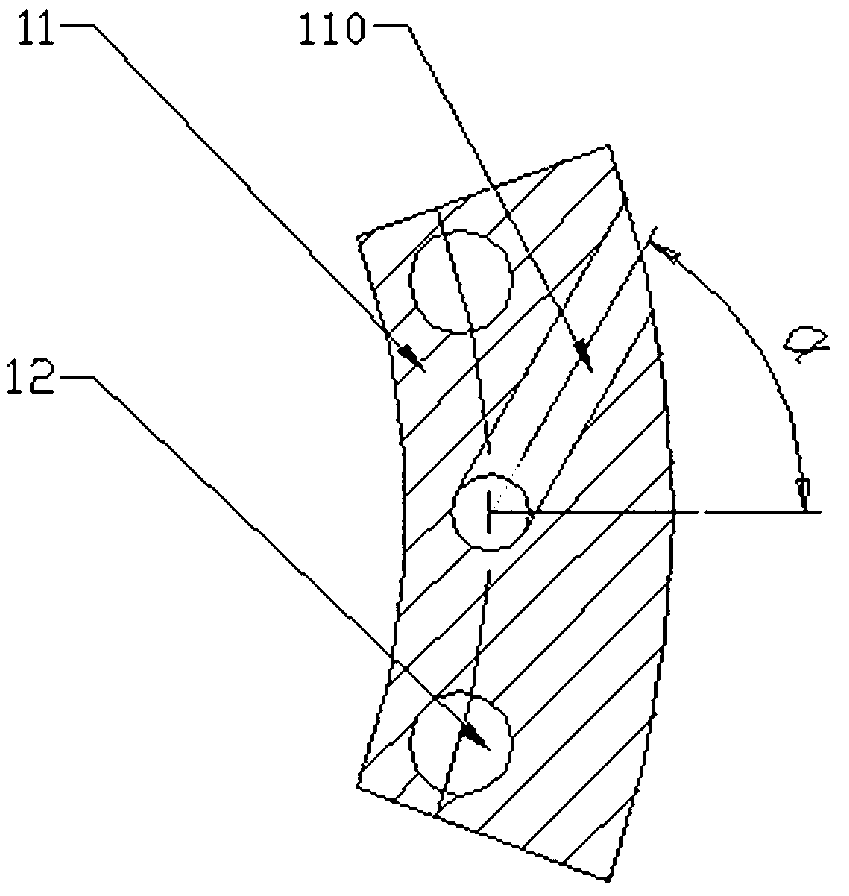

ActiveCN103322396AEnsure lubricating oilExtend your lifeCentrifugesEngine lubricationCouplingEngineering

The invention discloses a lubricating device for a high-speed bearing in a disc separator. The lubricating device comprises a vertical shaft, an oil inlet connector and an oil outlet connector. A coupling and a bearing block are sleeved on the vertical shaft. An oil slinger, at least one upper bearing, a spacer and a lower bearing are sequentially disposed on the vertical shaft inside the bearing block. A lower locking cap is disposed on the vertical shaft at the lower end of the bearing block. A belt pulley matching with the bearing block is connected to the tail end of the vertical shaft through a nut. The coupling is provided with a radial oil inlet. The upper end face of the bearing block is provided with a slant hole which deviates from the axis of the vertical shaft. The upper end of the slant hole is communicated with the oil outlet connector. An oil skimmer is connected to the lower end of the bearing block and is provided with a skimming hole. The skimming hole is communicated with the slant hole through a communicating hole in the bearing block. A gap is formed between the skimming hole and the inner wall of the belt pulley. The skimming hole radially deviates from the vertical shaft. The lubricating device has the advantages of good lubricating effect, long service life, simple structure, convenience in maintenance and low cost.

Owner:ANHUI SAIERTE CENTRIFUGE

Double-main-shaft numerical control lathe

InactiveCN106001626AReduce distortionAvoid deformationLarge fixed membersMetal working apparatusNumerical controlEngineering

The invention discloses a double-main-shaft numerical control lathe. The double-main-shaft numerical control lathe comprises a body, saddles, a two-degree-of-freedom truss manipulator and main shaft boxes; left and right two symmetric saddles are arranged on the body; left and right two symmetric main shaft boxes are arranged on the body; the left saddle is corresponding to the left main shaft box in position; and the right main shaft box is corresponding to the right saddle in position. The two main shaft boxes and the two saddles are symmetrically mounted on the body; the double-main-shaft numerical control lathe is matched with a truss manipulator for independently finishing machining of machined parts without needing matched use of two lathes, so that the floor area is reduced; and in addition, the numerical control lathe adopts symmetric layout, is uniform in stress during machining, reduces the deformation, and improves the machining precision and the stability. In addition, the truss manipulator is shorter in travel during working, so that the working efficiency is higher, and the market prospect is broad.

Owner:新昌县三特自动化科技有限公司

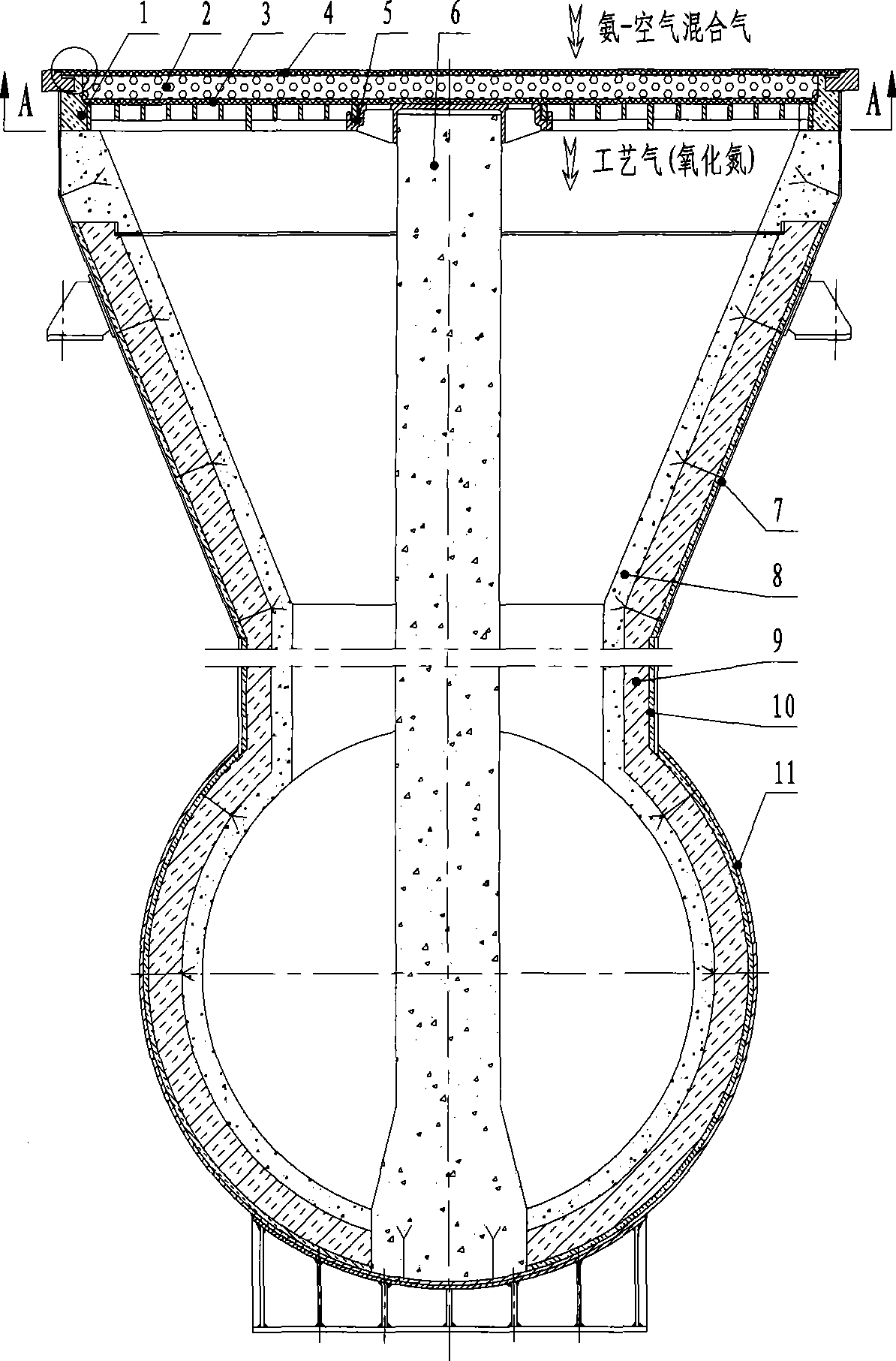

Ammoxidation furnace formed by novel platinum net brace that is catalyst basket and support structure thereof

ActiveCN101423202ASufficient deformation coordinationNormal design service lifeNitric acidWire gauzeFiber

The invention relates to an ammonia oxidation stove consisting of a novel platinum net bracket-based catalyst frame and a supporting structure thereof; a concrete vertical column is erected at the center of a pipe box in front of an oxidation furnace / waste boiler; furthermore, the upper end of the concrete vertical column supports a bracket which is provided with screens so as to form a CDM catalyst frame; the CDM catalyst is provided with a platinum net; the circumference of the bracket-based catalyst frame is heat-insulated by a ceramic fiber blanket; when the CDM catalyst is not loaded, the screen is canceled and the platinum net is directly arranged on the bracket. The ammonia oxidation stove has the advantages that the bracket is made of high-temperature alloy HP-Nb or HK-40 which generates no high-temperature oxidation even under a use state of high temperature; furthermore, the bracket has enough bending section modulus under the use temperature, has simple structure and smaller manufacture difficulty; furthermore, the ammonia oxidation stove completely meets the requirement of installation of the platinum net and the filling of a catalyst which is used for emission reduction of N2O for the newly increased CDM project, leads the platinum net and the catalyst to be the best condition of horizontal surface when in use, ensures the platinum net and the catalyst to achieve the normal design service life; the ammonia oxidation stove belongs to maintenance-free design, and reduces the shutdown maintenance time of the system, the maintenance expense and the heat dissipation loss of the oxidation stove.

Owner:SICHUAN LUTIANHUA

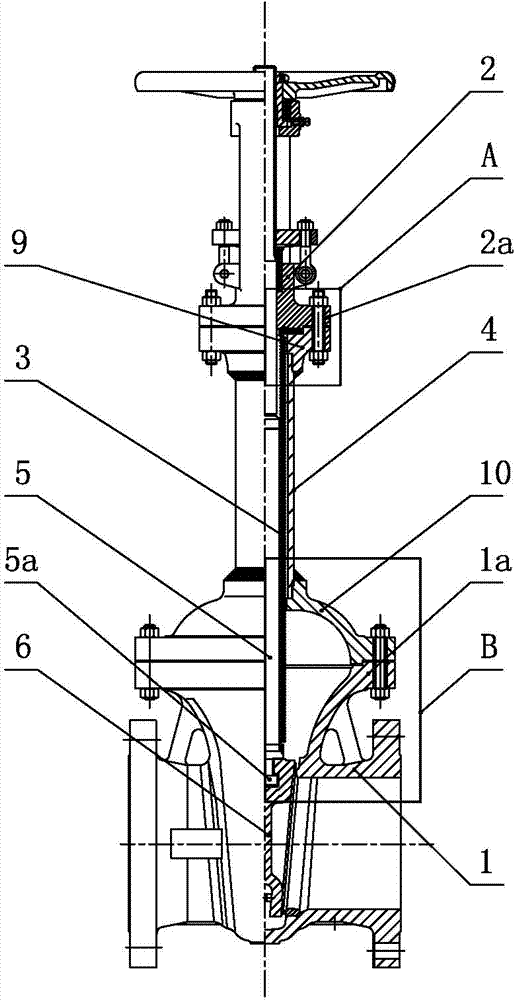

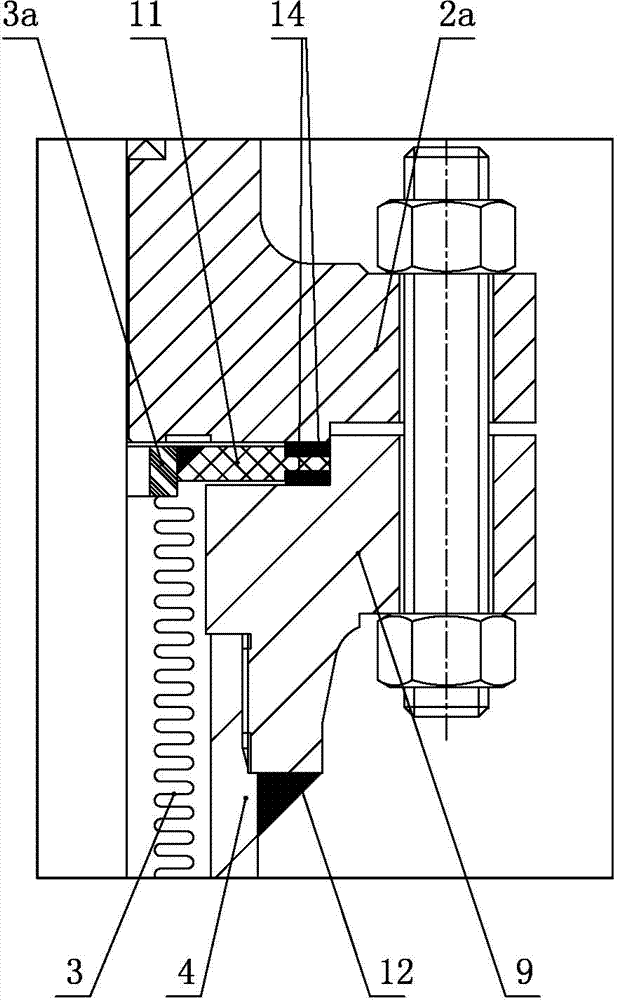

Corrugated pipe brake valve

ActiveCN103968147AImprove sealingSolve technical problems that are difficult to weldSpindle sealingsValve housingsThree stageEngineering

The invention discloses a corrugated pipe brake valve, comprising a valve body, a valve deck, a corrugated pipe sleeve, a corrugated pipe running through the corrugated pipe sleeve and a valve rod running through the corrugated pipe, wherein a stuffing box is arranged on the valve deck around the valve rod; a filler is filled into the stuffing box; a flashboard is connected inside the valve body through a valve seat; the upper end of the valve rod running through the valve deck and is connected with a hand wheel; a T-shaped connector is arranged at the lower end of the valve rod; a T-shaped groove is formed in the flashboard; the T-shaped connector is arranged inside the T-shaped groove and is in clearance fit with the T-shaped groove; a valve deck flange which is arranged integrally with the valve deck is arranged on the valve deck; a valve body flange which is arranged integrally with the valve body is arranged on the valve body; an upper flange which is fixedly and tightly connected with the valve deck flange is arranged at the upper end of the corrugated pipe sleeve; a lower flange which is fixedly and tightly connected with the valve body flange is arranged at the lower end of the corrugated pipe sleeve. The corrugated pipe brake valve adopts a three-stage connection structure of the valve deck, the corrugated pipe sleeve and the valve body, and the processing and casting difficulty is significantly reduced.

Owner:KUSN WEISA VALVE

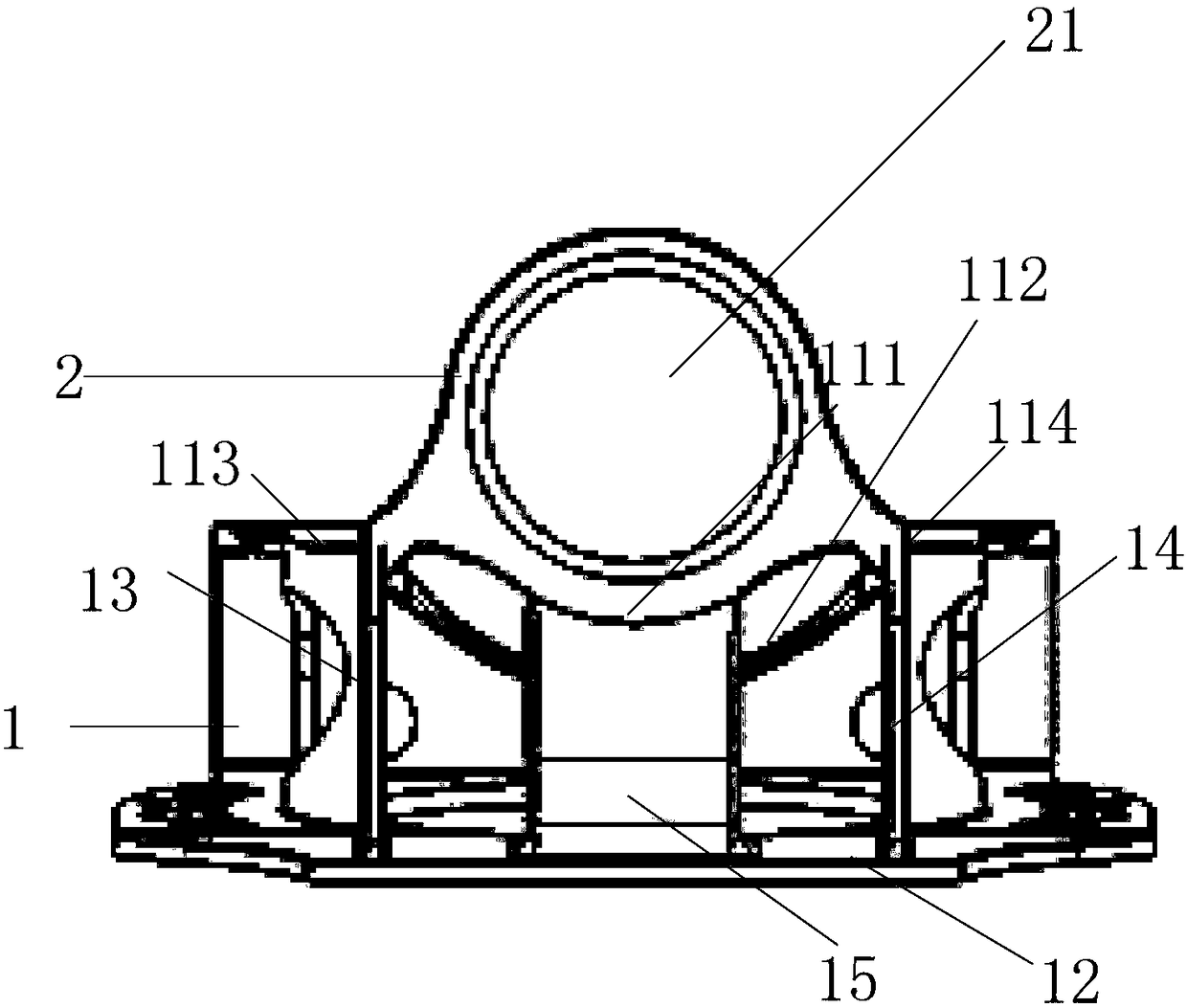

Water pump support where water pump volute is integrated

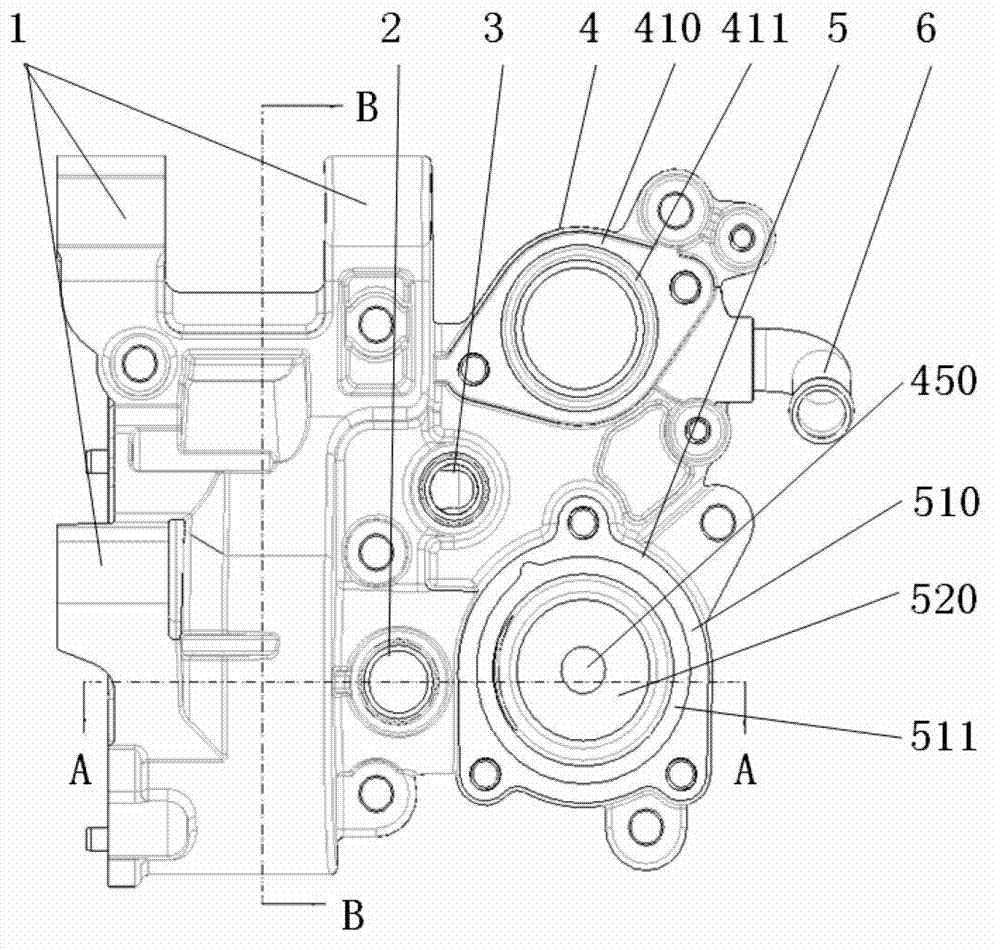

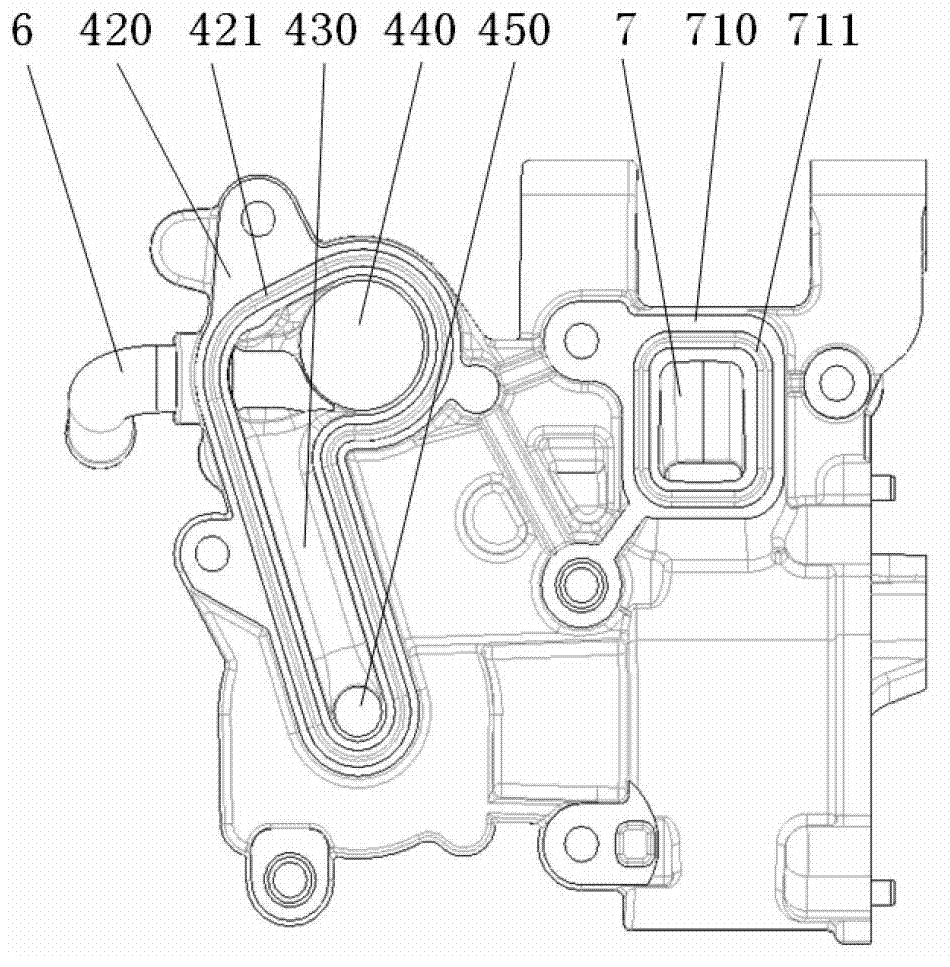

ActiveCN103195734AReduce casting difficultyIncreased failure ratePump componentsPumpsGasolineEngineering

The invention provides a water pump support where a water pump volute is integrated. The water pump support comprises the water pump volute, a cylinder body water jacket water inflow channel, a thermoregulator accommodating chamber and a cylinder body water jacket water outflow channel. The water pump support further comprises an A steel pipe integrated on the water pump support, a B steel pipe, a C steel pipe and lug parts which are located on the outer edge of the water pump volute and are distributed in a radial mode. The water pump volute is integrated on the water pump support, cylinder casting difficulty is reduced, machining does not need to be performed on the side of a cylinder body, and the reject ratio and increase of cost can be controlled. Connecting lines are fewer, the water pump support is convenient to arrange and compact in structure and integrates various functions, the problem of difficulty in arrangement of a small supercharge direct injection gasoline engine at present is solved, assembling working hours can be reduced simultaneously, and takt time is met.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Six-gear single-middle-shaft transmission

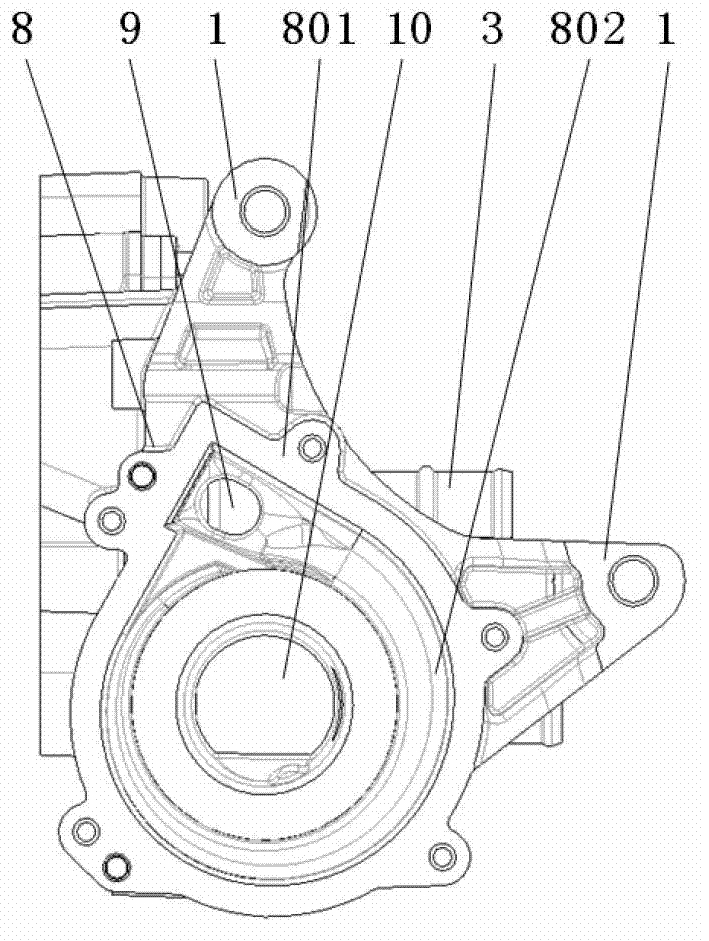

ActiveCN105697739AReduce casting difficultyOptimize layoutControlled membersToothed gearingsEngineeringFlange

The invention relates to a six-gear single-middle-shaft transmission. The six-gear single-middle-shaft transmission comprises a middle shaft and an input shaft integrated with an input gear. The input gear is constantly meshed with a middle shaft transmission gear mounted at the front end of the middle shaft, a main shaft is mounted above the middle shaft, a middle shaft gear on the middle shaft is constantly meshed with a main shaft gear on the main shaft, and the rear end of the main shaft is connected with an output flange disc; the main shaft gear comprises a first-gear gear, a second-gear gear, a third-gear gear, a fourth-gear gear, a fifth-gear gear, a sixth-gear gear and a reverse-gear gear, and synchronizers are mounted between the first-gear gear and the second-gear gear, between the third-gear gear and the fourth-gear gear, and between the fifth-gear gear and the sixth-gear gear; gear shifting forks are arranged on synchronizer sliding sleeves on the synchronizers and a reverse-gear sliding sleeve on the reverse-gear gear in a straddling manner; a pull plate is clamped to the upper ends of the gear shifting forks and is connected with a control mechanism; and the pull plate is mounted on a shell through a supporting structure. The pull plate connected with the control structure is arranged to form a pull plate type control execution mechanism, the gear shifting performance is good, shell casting difficulties and the casting failure ratio are reduced, and meanwhile the boundary dimension is reduced.

Owner:SHAANXI FAST GEAR CO

Hydrodynamic retarder

InactiveCN103185085AImprove braking effectIncrease braking torqueLiquid resistance brakesEngineeringOblique angle

The invention provides a hydrodynamic retarder. The hydrodynamic retarder comprises a turning wheel and a fixed wheel, wherein blades of the turning wheel and the fixed wheel are U-shaped and are arranged along the radial directions of the turning wheel and the fixed wheel; the U-shaped blades of the turning wheel and the fixed wheel are arranged in opposite directions; oil fluids in an inner ring and an outer ring of a hydrodynamic circulating cavity are fully centralized to a place with the largest axial hydrodynamic circulating circle for impacting and stirring; the front end of each blade is thin and the middle part of each blade is thick; a taper oblique angle is formed at the front end of each blade; the upper surface of each blade is an arc-shaped; the semicircular arc-shaped surface on the upper surface of the two U-shaped blades arranged in opposite directions forms another circulating circle between the turning wheel and the fixed wheel; stirring circulating impact can be carried out on the upper part of the blade to further enhance mutual impact of liquid flow; the casting connection area between the U-shaped blades, the fixed wheel and the turning wheel is large; the two sides of eawch blade are similar to two support ribs so as to enhance the rigidity of the blades; the structure is firm and unlikely to be damaged; and by increasing the diameter of the circulating circle, the axial size of the whole transmission is reduced, the occupation space is small, and the casting difficulty is low.

Owner:西安双特智能传动有限公司

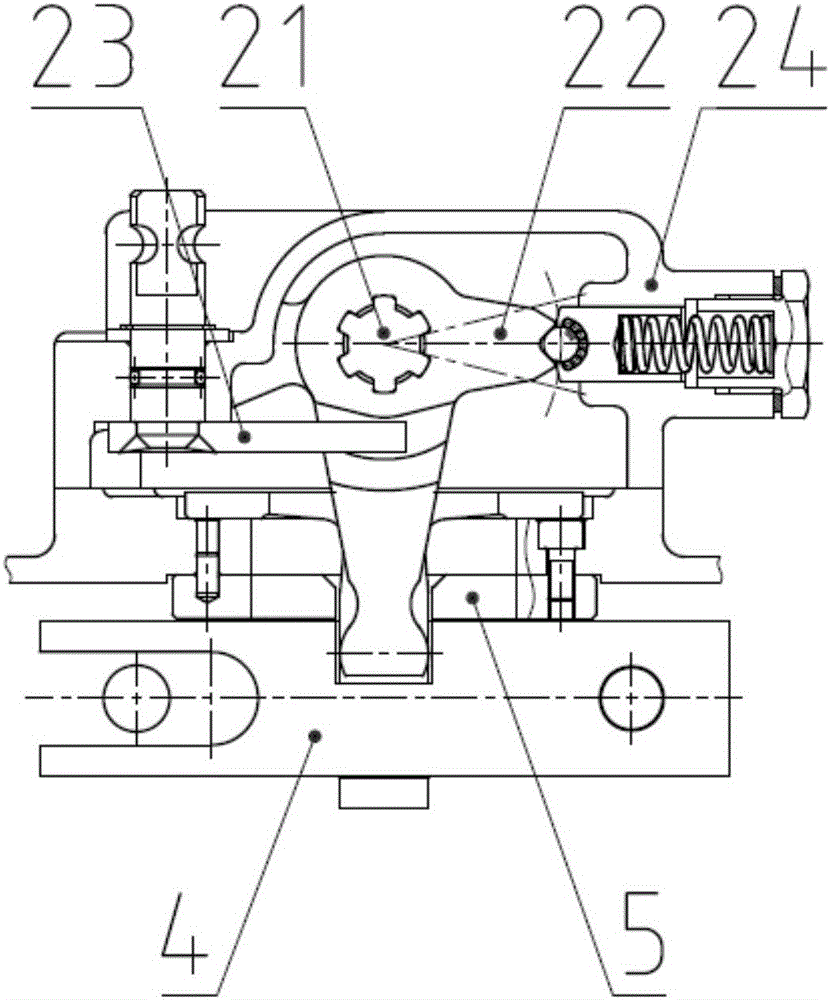

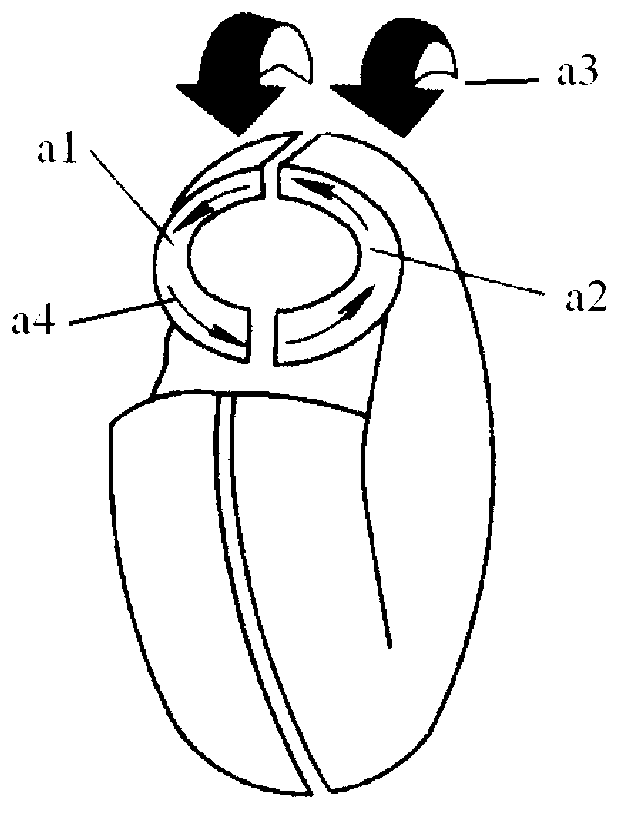

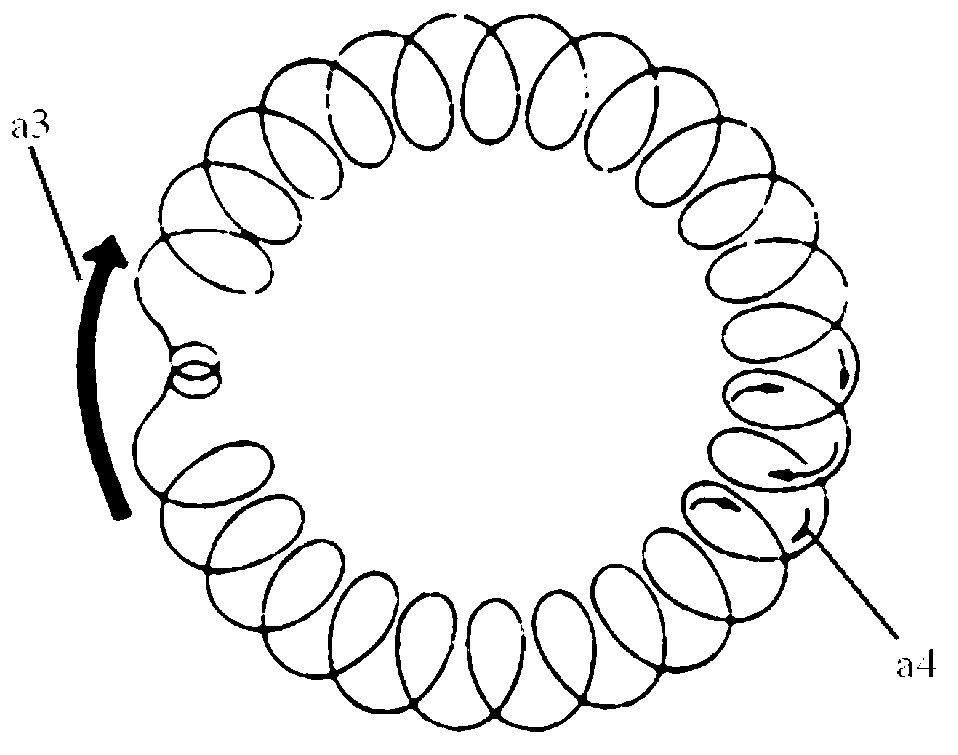

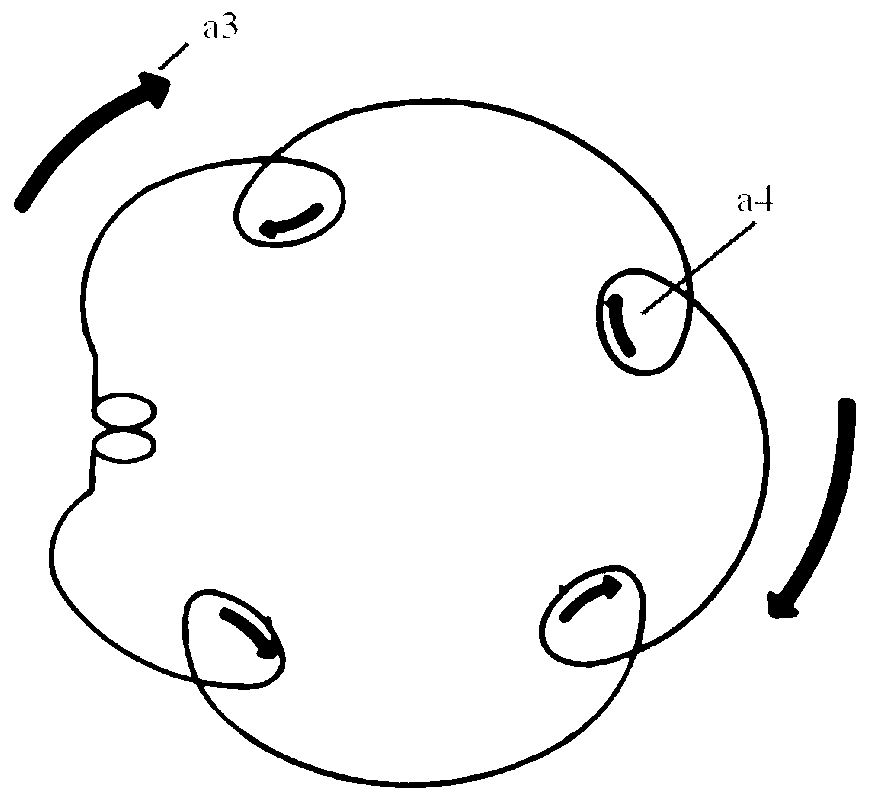

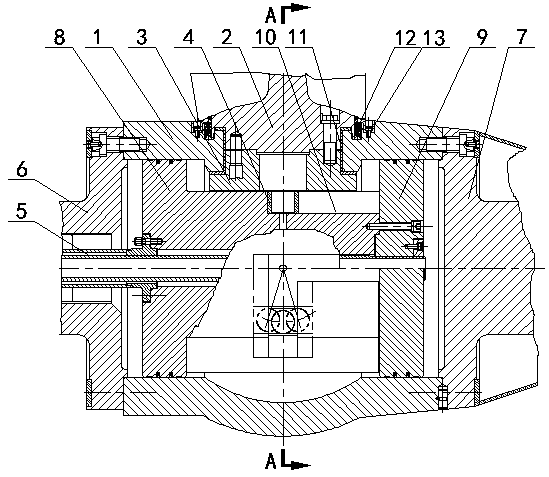

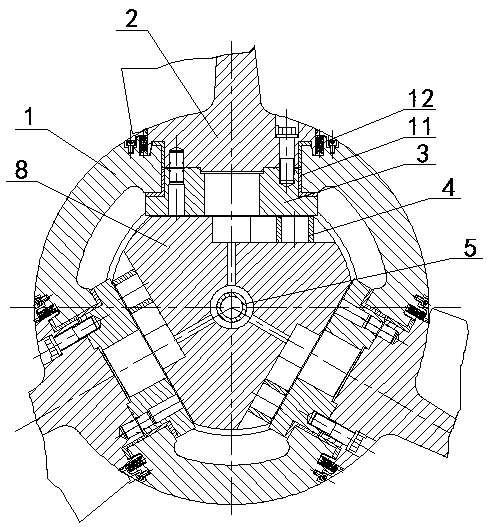

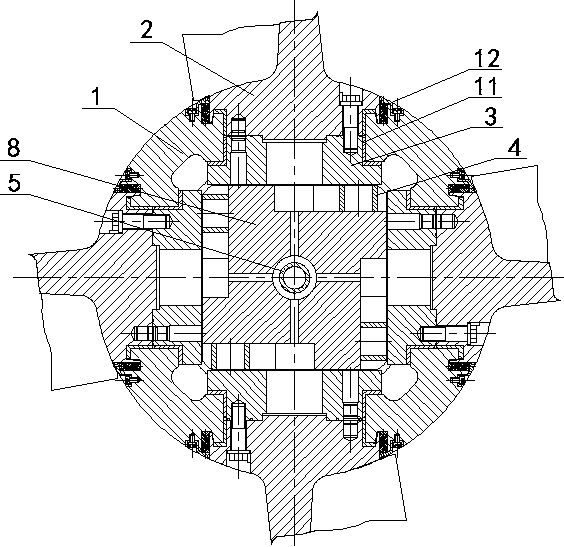

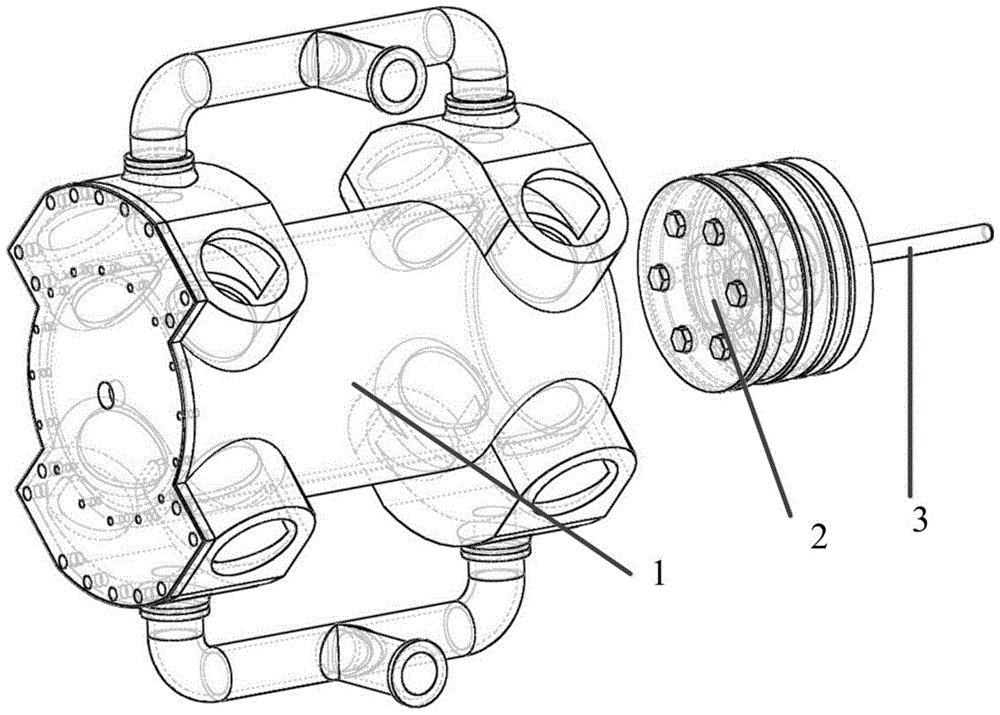

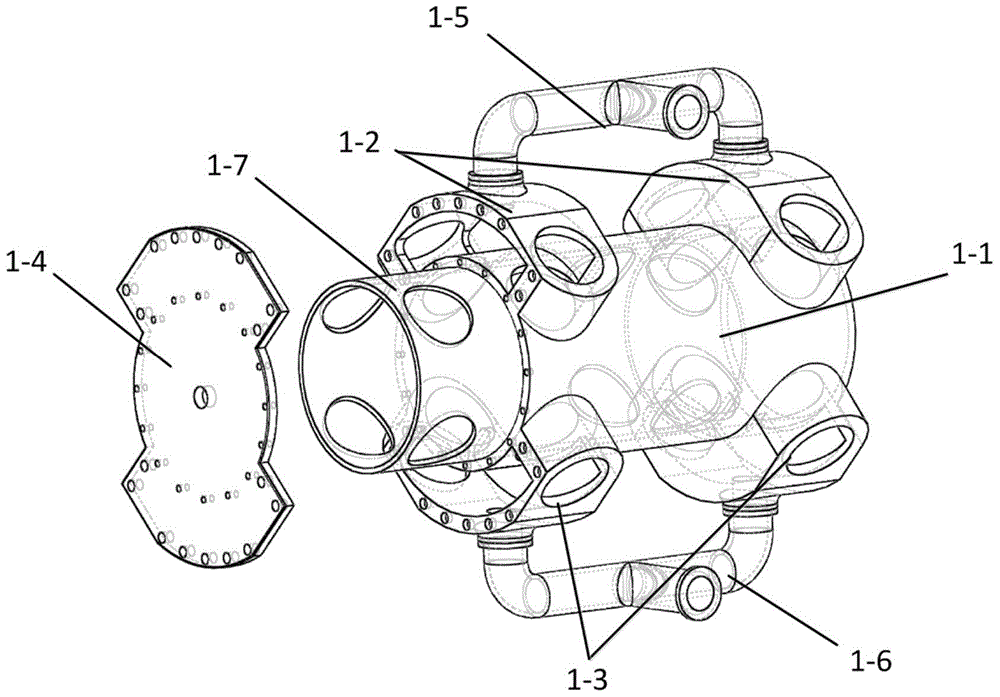

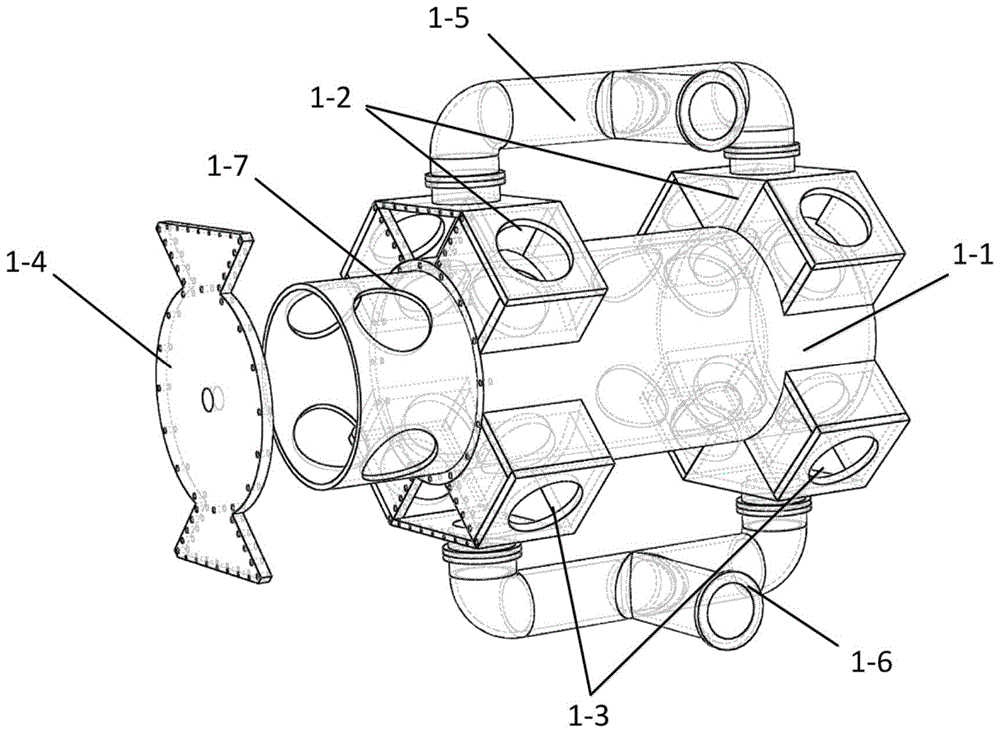

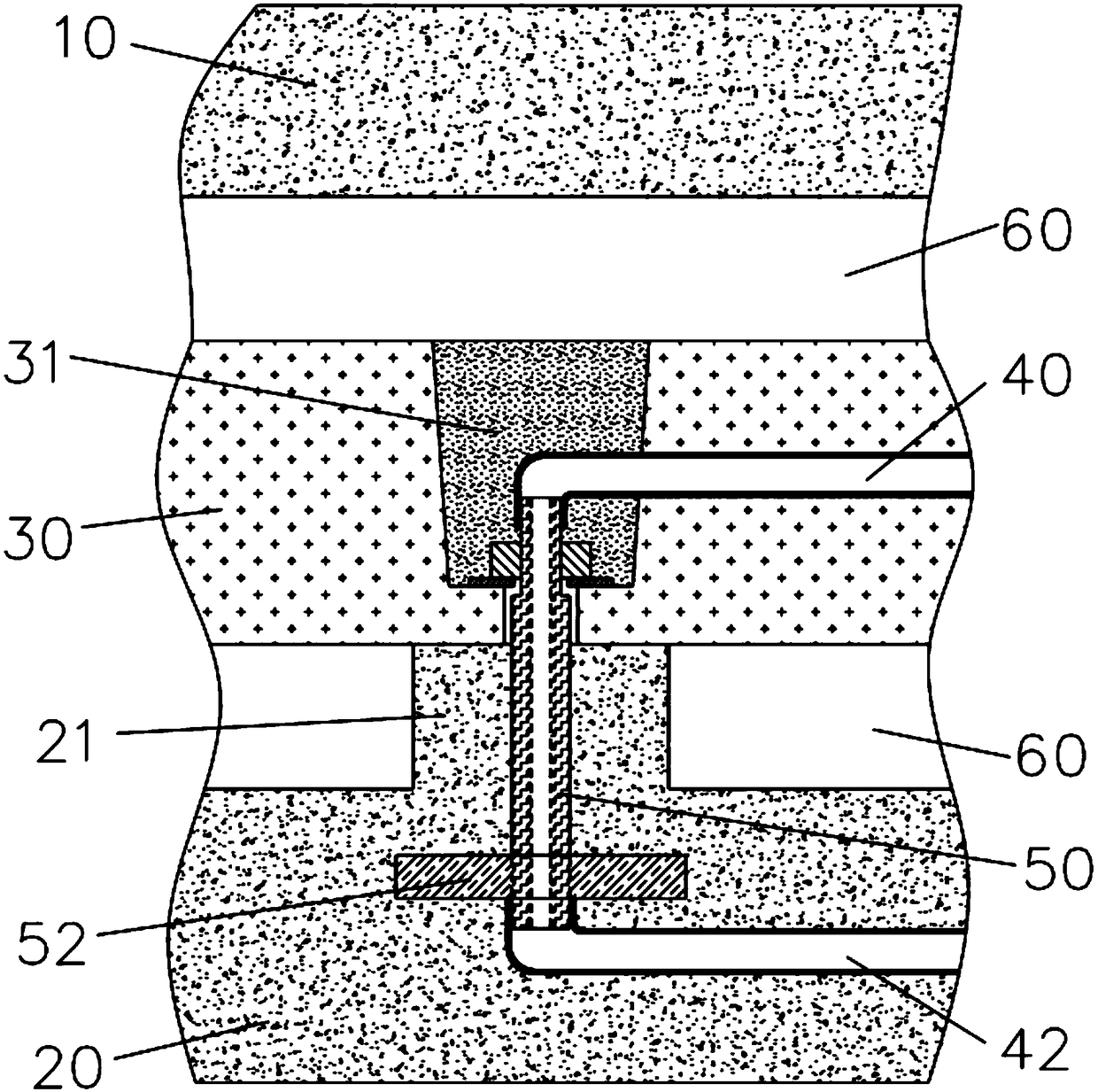

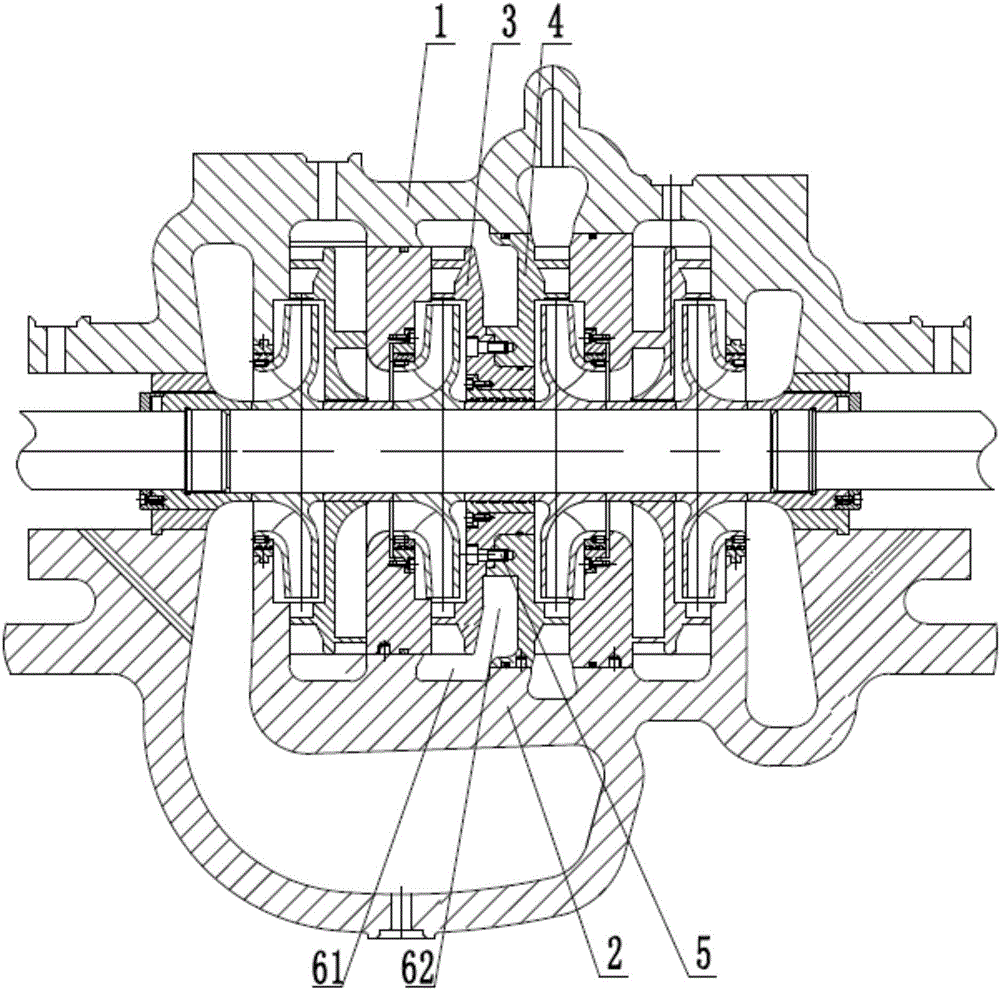

Rotation paddle type water turbine paddle operation mechanism

PendingCN110566393AIngenious structural designEasy to useFinal product manufactureHydro energy generationWater turbineTurbine

The invention discloses a rotation paddle type water turbine paddle operation mechanism. A runner body is included and provided with at least three blades. A rocker connected with the blades is arranged in the runner body. The center of the runner body is provided with a piston mechanism with a sliding block. The sliding block is connected with the rocker. An operation oil pipe is arranged at thecenter of the piston mechanism. The two ends of the piston mechanism are provided with a short shaft and a main shaft which are connected with the runner body correspondingly. The rotation paddle typewater turbine paddle operation mechanism has the advantages that structure design is ingenious, usage is reliable, and cost is low; meanwhile, by means of the rotation paddle type water turbine paddle operation mechanism, the paddle motion track can be opened in a limited manner in the preset range; friction pairs are reduced, and the transmission efficiency is higher; the arrangement of the number of water turbine rotation part components is reduced; the occupied structure space is reduced, and the structure is more compact; the runner body is simplified to be only provided with an outer layer instead of an inner layer and an outer layer, and the casting and machining difficulty is lowered; and the design and manufacturing period is shortened, and cost is reduced.

Owner:CHONGQING WATER TURBINE WORKS

A kind of optimal design method of guide vane airfoil of axial flow pump

The invention relates to an improvement of a traditional axial pump vane airfoil design method, and provides a novel axial pump vane airfoil optimizing design method. The method has the advantages that the strength of a vane is effectively improved, the service life of the vane is prolonged, the casting difficulty of the vane is reduced, the vane drawing time is greatly shortened, the labor is saved, and the hydraulic performance of the vane is ensured. The method is characterized in that the sharp parts at the inlet and outlet ends of the back surface of the vane airfoil are changed into the circular arc transition, and the parts near the inlet and outlet ends are properly thickened; the placing position of the vane is determined by using the profile placing angle to replace the vane inlet and outlet placing angle; the vane airfoil is designed according to the following main parameters, namely chord length l, working surface profile radius R1, back surface profile radius R2, vane inlet circular arc radius r1, vane outlet circular arc radius r2, and profile placing angle alpha L.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

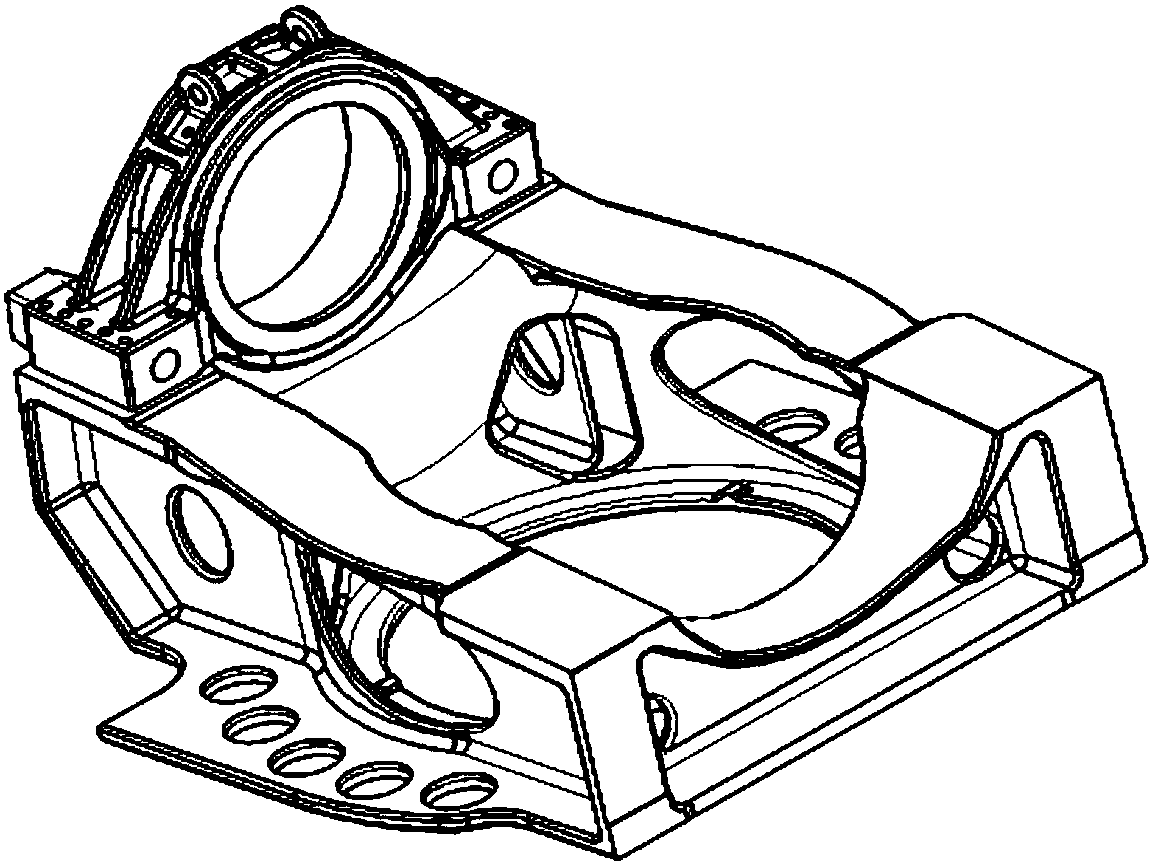

Component for combining bearing pedestal and front frame and wind generating set

ActiveCN108087217AReduce weightReduce dosageWind motor supports/mountsMachines/enginesMechanical engineeringThin walled

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

A design method of guide vane of submersible axial flow pump and guide vane of submersible axial flow pump

ActiveCN103644140BImprove operational reliabilityHigh strengthPump componentsPumpsAxial-flow pumpImpeller

The invention provides a method for designing a submersible axial-flow pump guide vane and a submersible axial-flow pump guide vane. According to the method, the entry guide vane hub diameter Dh, the entry guide vane outer diameter D2, the guide vane entry inclination angle epsilon1, the guide vane inner side divergence angle alpha, the guide vane outer side divergence angle beta, the guide vane inner flow line length alpha1 and the guide vane outer flow line length beta1 of the submersible axial-flow pump guide vane are determined on the basis of the hub diameter and the guide vane outer diameter of a submersible axial-flow pump guide vane wheel. Design can be rapidly achieved, manpower is saved, and the performance curve of the submersible axial-flow pump guide vane coincides with a required performance curve. Compared with a traditional design method for a submersible axial-flow pump guide vane, lift and efficiency are improved, ranges of efficient areas are widened, and operational reliability of the submersible axial-flow pump guide vane is improved.

Owner:JIANGSU KAIQUAN PUMP IND MFG

Structure of Working Chamber Components of Cryogenic Cylinder for Liquefied Natural Gas Evaporated Gas Compressor

ActiveCN104747405BAvoid heatingSimple structurePositive displacement pump componentsPumpsExhaust valveEngineering

The invention discloses a low-temperature air cylinder working chamber component structure of a liquefied natural gas vapor compressor. The low-temperature air cylinder working chamber component structure of the liquefied natural gas vapor compressor comprises an air cylinder, a piston and a piston rod. A cylinder body of the air cylinder is of a single-wall cylinder type with two open ends, two air inflow valve cages located at the two ends of the cylinder body are arranged at the upper end of the cylinder body, and two air release valve cages located at the two ends of the cylinder body are arranged at the lower end of the cylinder body. According to the low-temperature air cylinder working chamber component structure of the liquefied natural gas vapor compressor, the air cylinder is of a single wall structure, the structure is simple, and casting is facilitated. The valve cages can be cast and formed together with the air cylinder body, and the valve cages can also be welded to the air cylinder by combining plurality of steel plates in a welding method. Due to the fact that the air cylinder body only has the single wall, heat conducted to an upper air suction part through an exhaust part with high temperature during operating can be reduced, inflowing air is effectively prevented from being heated, and more energy is saved in the compressing process. The outward ends of the air inflow valve cages and the outward ends of the air outflow valve cages are open, a plurality of fastening screw holes are formed, an air cylinder cover also serves as outer walls of the valve cages, bolts are used for fastening, and casting difficulty can be further lowered.

Owner:XI AN JIAOTONG UNIV

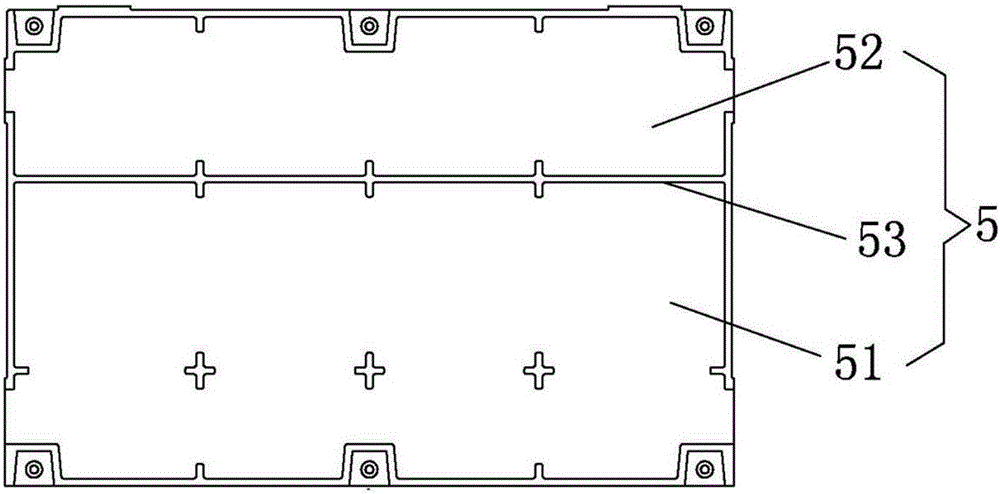

Folding type wide film extrusion die design method

The invention discloses a folding type wide film extrusion die design method which comprises an upper die and a lower die. At a die closing state, a flow distributor holding chamber on the front part and a V-shaped runner chamber on the back part are formed between the upper die and the lower die; a flow distributor is clamped and fixed into the flow distributor holding chamber; a circular blind hole chamber is arranged in the front part of the flow distributor; the V-shaped fishtail-type runner chamber is arranged on the back part of the flow distributor; the front end of the V-shaped fishtail-type runner chamber communicates with the circular blind hole chamber; the back end of the V-shaped fishtail-type runner chamber communicates with the front end of the V-shaped runner chamber; a die extrusion port is formed in the back end surface, passing through the upper die and the lower die, of the back end of the V-shaped runner chamber; and an extrusion port is formed in the front end surface, communicating with the upper die and the lower end, of the front end of the circular blind hole chamber. According to the folding type wide film extrusion die design method provided by the invention, an extrusion melt body is innovatively designed to be of a V-shaped folding type structure at a pre-forming section and a forming section, and the dimension of a die along a width direction is reduced, so that the difficulty in casting and designing the die is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

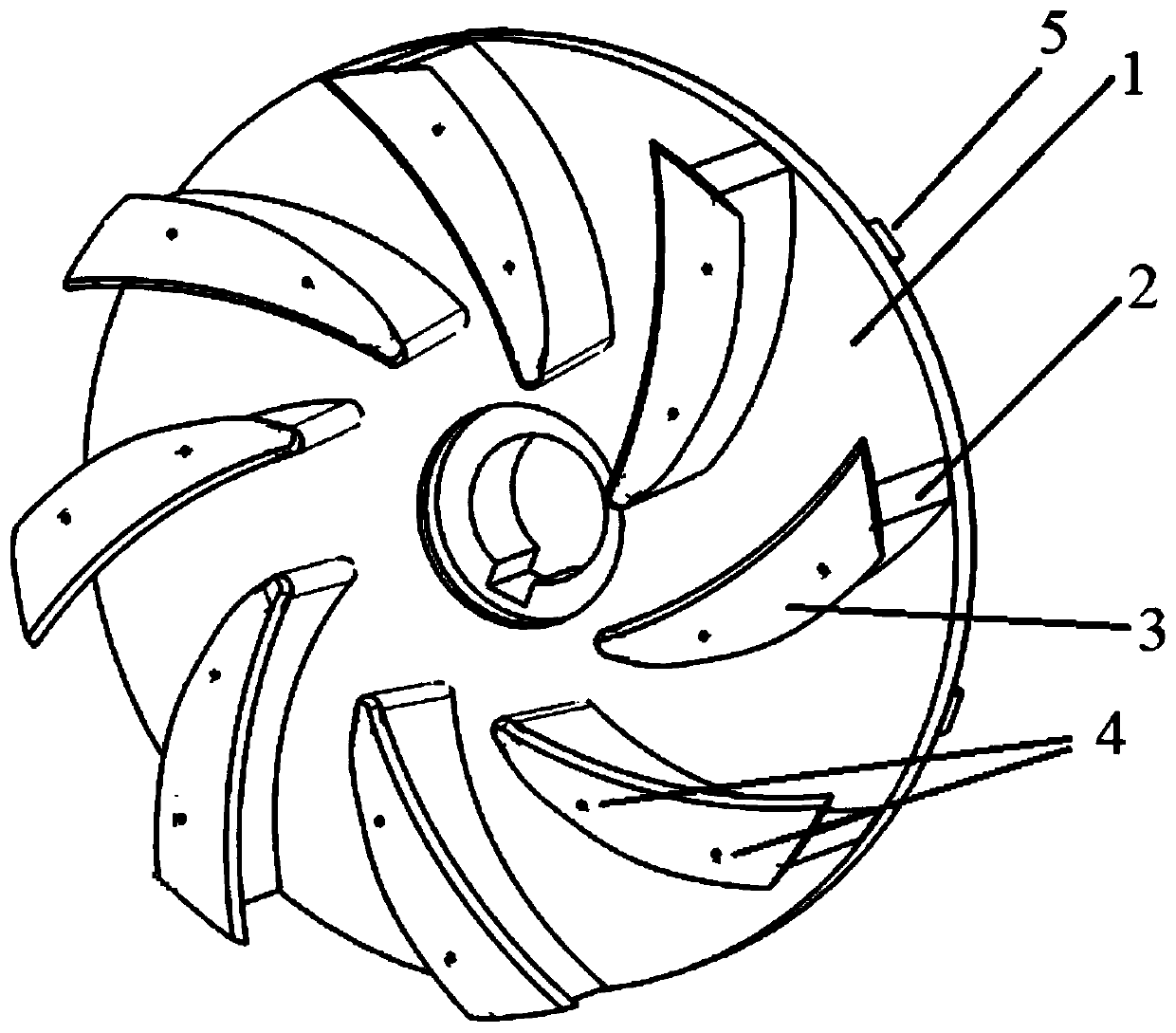

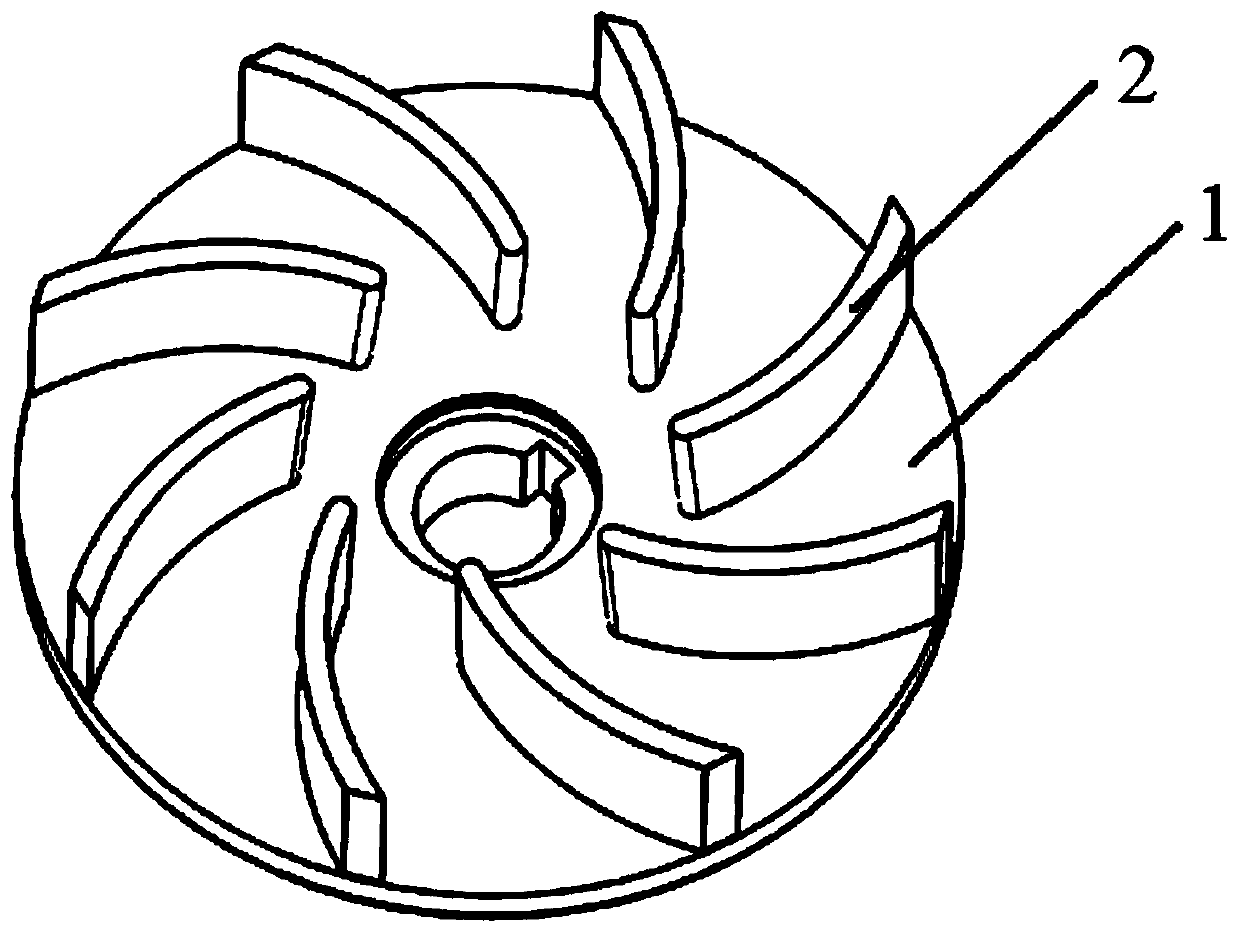

Environmental-friendly pump for conveying media with particles and fiber

The invention relates to an environmental-friendly pump for conveying media with particles and fiber. The environmental-friendly pump comprises a motor and a pump shaft, wherein the pump shaft passesthrough a pump cover; then, the tail end is positioned in a pump case; the pump case is connected with the base; an impeller is arranged on the pump shaft; a front cover plate and a back cover plate are arranged on the impeller; the front cover plate is right aligned with the base; an opening ring is arranged on the base; a blade on the impeller is projected out the front cover plate and is aligned with the end surface of the base side for a certain distance; the part, projected out of the front cover plate, of the blade is positioned in the opening ring. The manufacturing and processing difficulty of the pump and the impeller weight are reduced by improvement on the basic structure of a submersible sewage pump, so that the non-blockage performance and non-overload performance of the pumpare improved.

Owner:JIANGSU UNIV +1

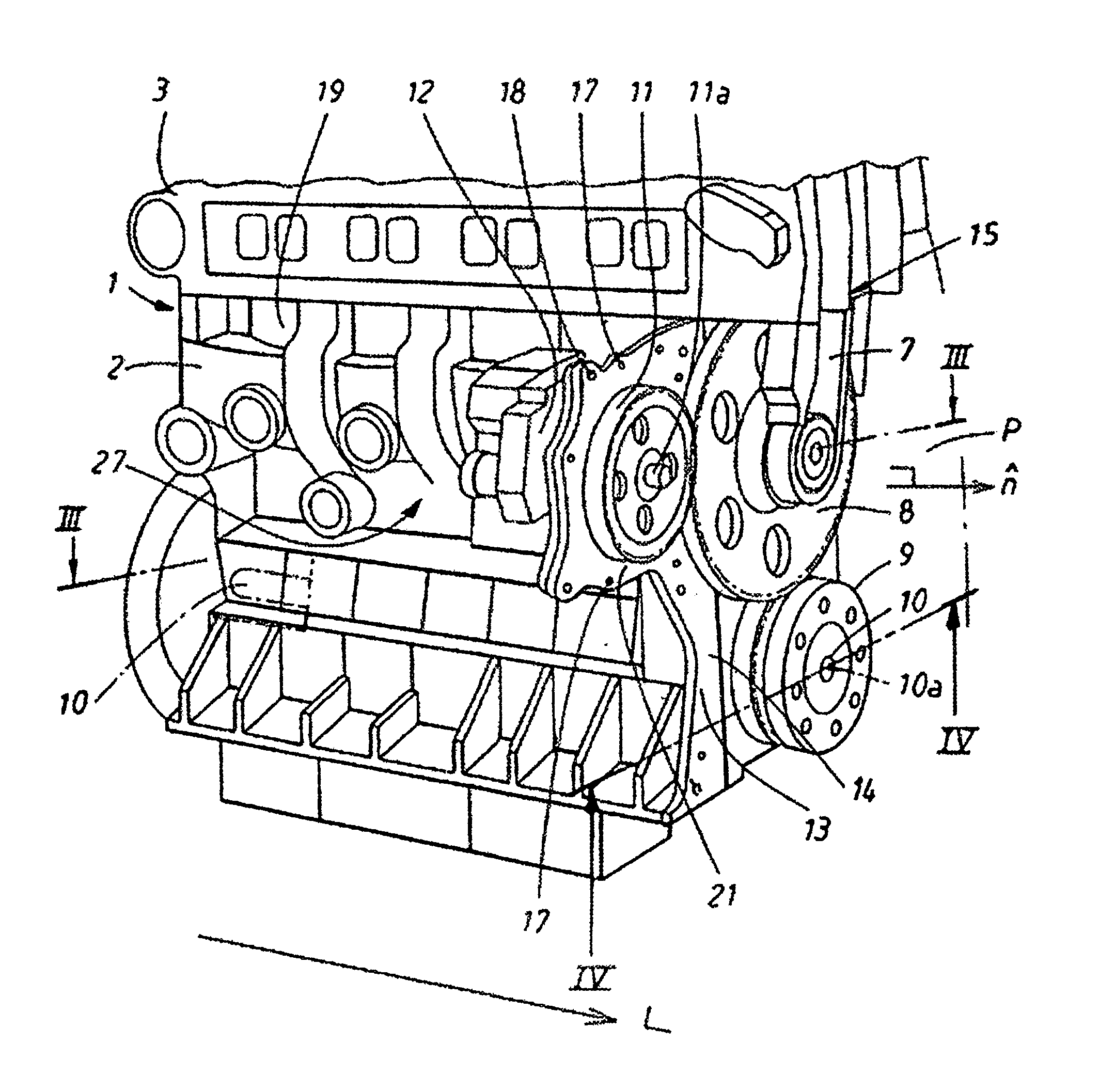

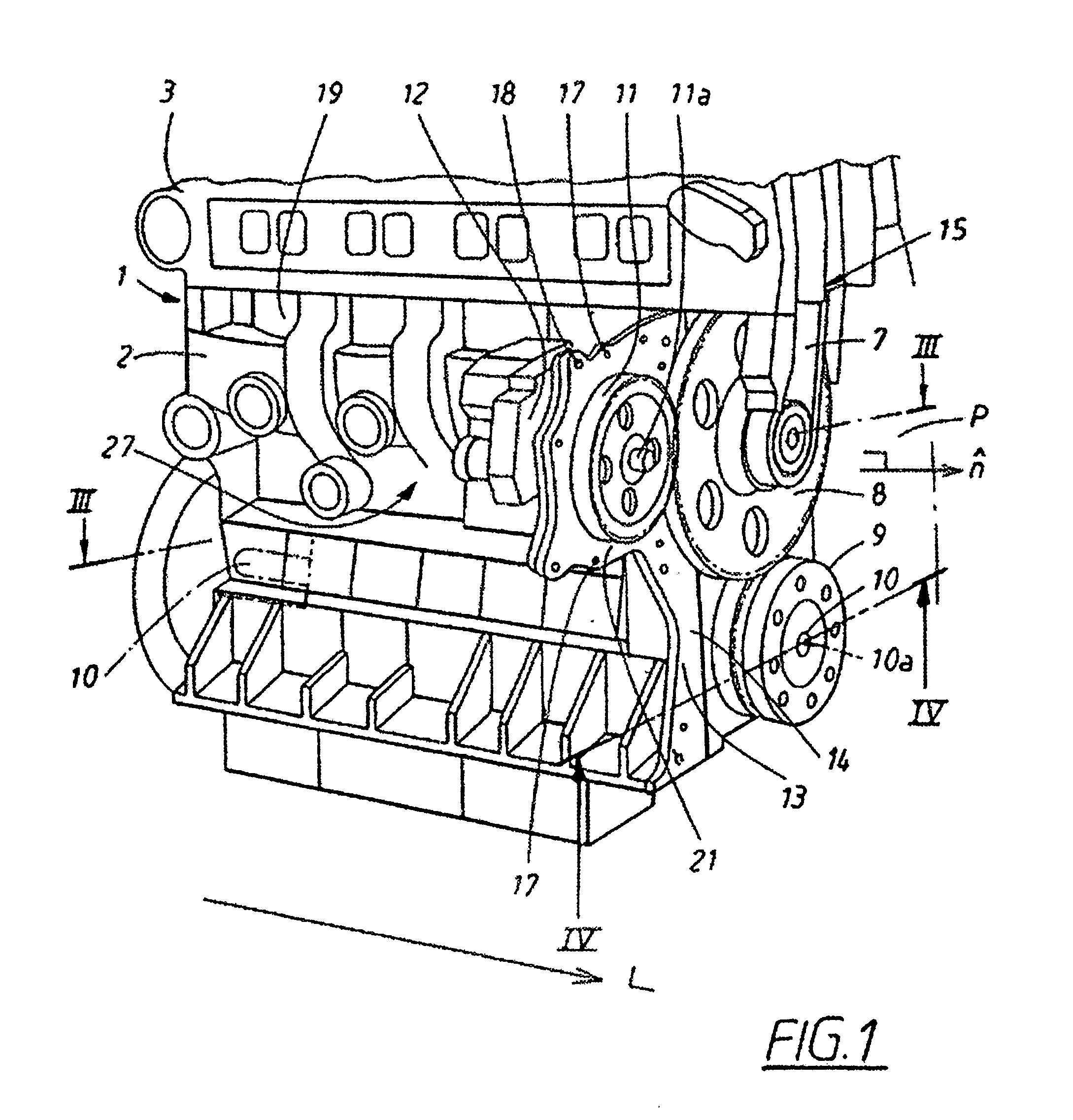

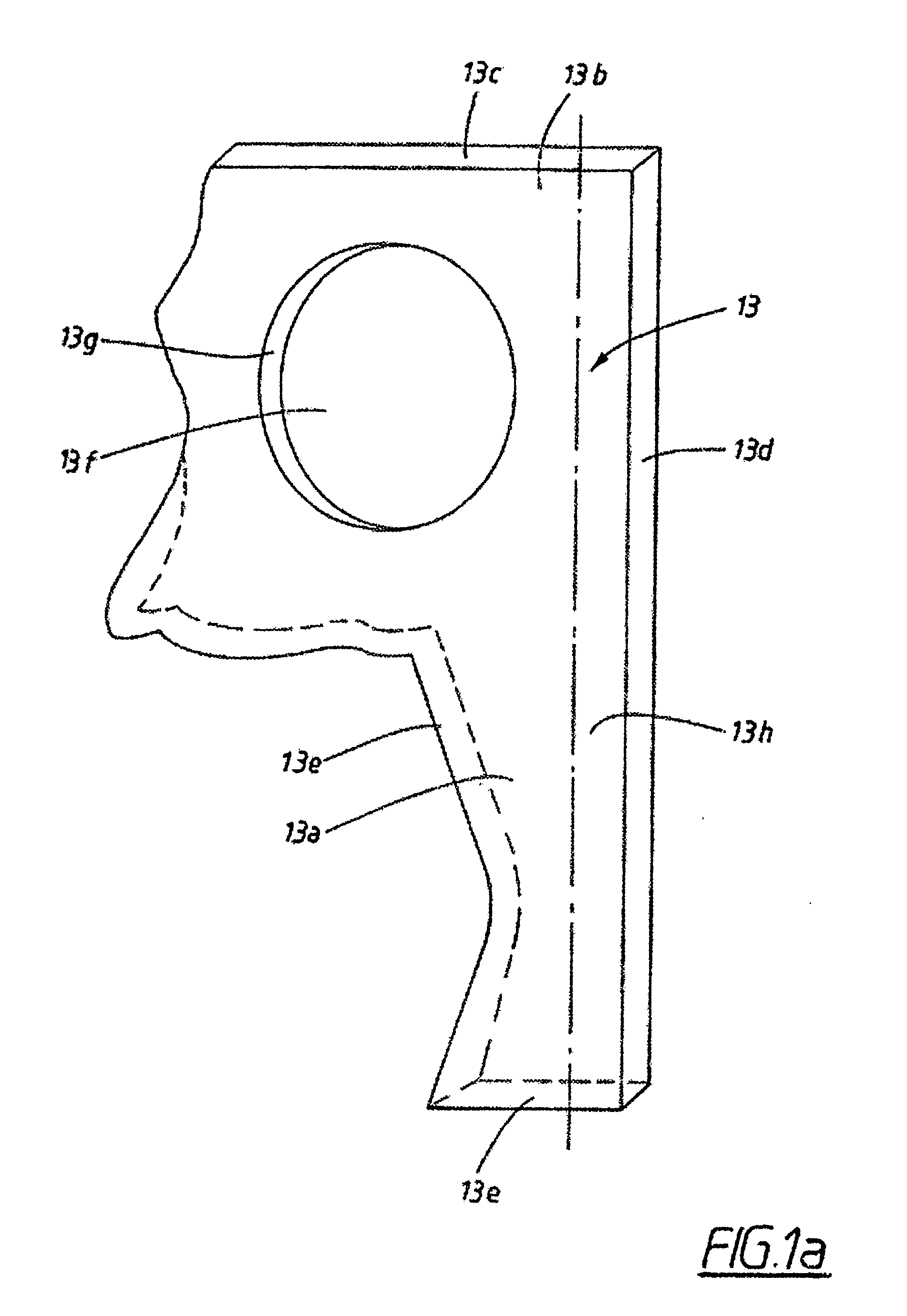

Mounting board

InactiveUS20080017163A1Avoid difficultyReduce casting difficultyCasingsMachine framesEngineeringInternal combustion engine

An internal combustion engine including an engine block provided with an ear portion arranged to carry an auxiliary device driven by a power take off arranged on a crank shaft mounted in said engine block.

Owner:VOLVO PENTA AB

Casting mold and casting method for casting slender oil pipe castings

ActiveCN106734964BAchieve positioningEasy to fixFoundry mouldsFoundry coresCasting moldMaterials science

A casting mold for fabricating slender oil pipe type castings comprises an upper sand mold, a lower sand mold, a sand core, an air-out structure, and a fixation structure. The air-out structure comprises a sand core interior air passage arranged in the sand core and a sand mold interior air passage arranged in the lower sand mold. The sand core interior air passage is arranged in a length direction of the sand core, and the sand mold interior air passage is arranged in a length direction of the lower sand mold. The fixation structure comprises a ventilating connecting rod. An upper end of the ventilating connecting rod passes through a via hole in the lower sand mold and a standard core hole of the sand core and into a sand filling area to be hermetically connected with the other end of the sand core interior air passage, and a lower end of the ventilating connecting rod is hermetically connected with one end of the sand mold interior air passage. In the invention, the fixation structure is arranged as a hollow air-out chamber, thereby achieving smooth air discharge from the oil pipe sand core under the premise of satisfying molding sand thicknesses of a side surface of an oil pipe and a lower core head of the lower sand mold, fundamentally solving the problems of fixation and air discharge of the slender sand core, and greatly lowering the casting difficulty of castings of such a structure.

Owner:KOCEL EQUIP

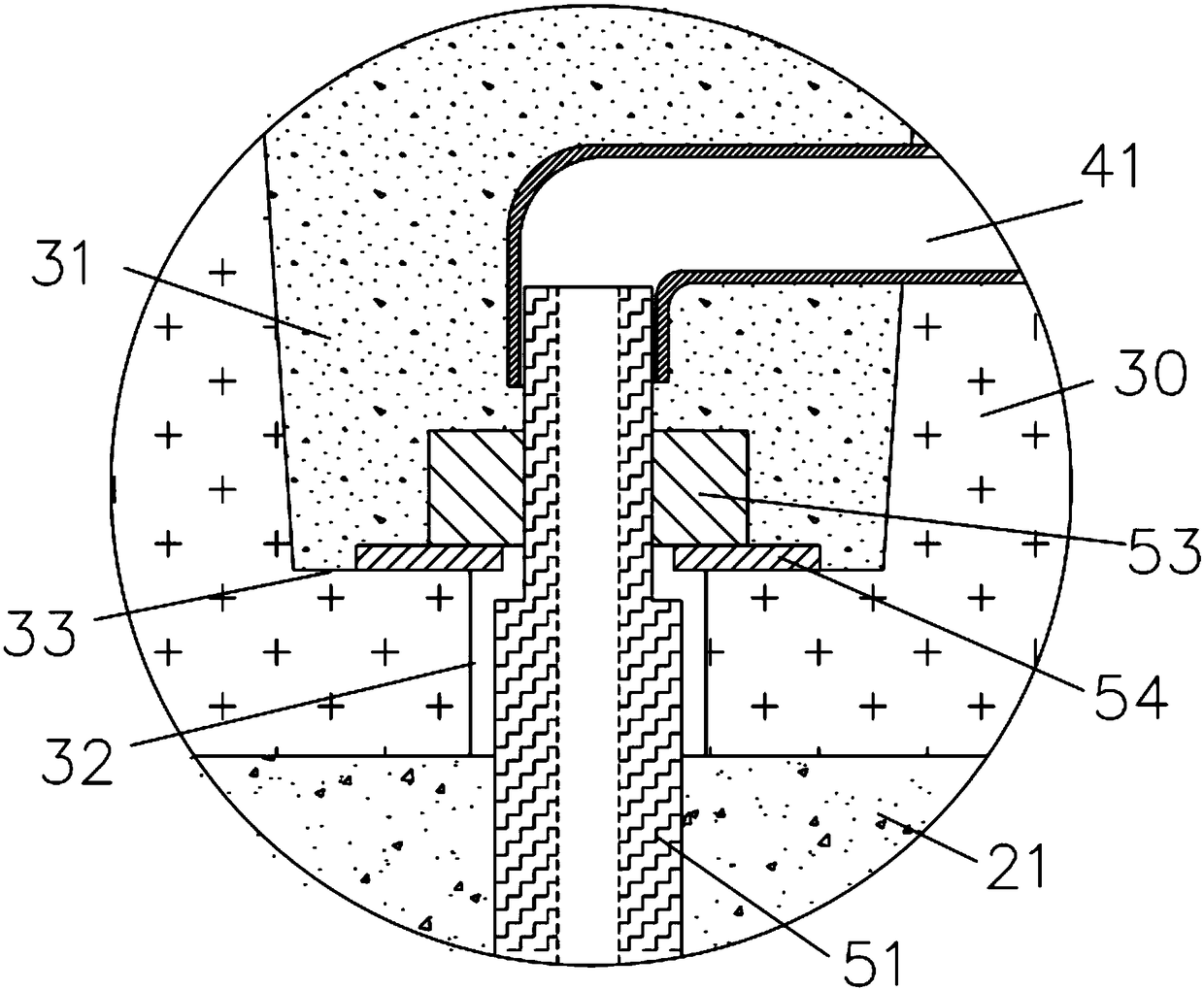

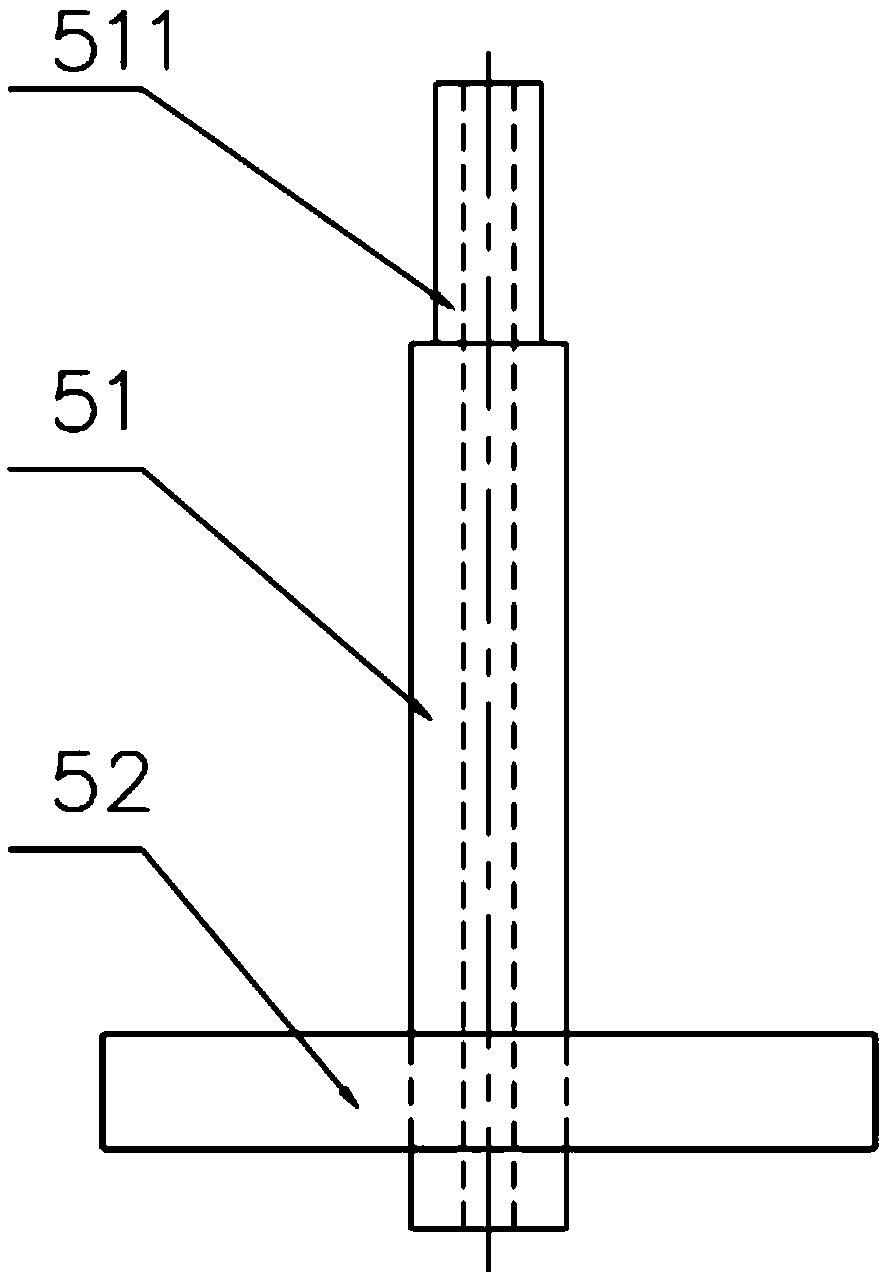

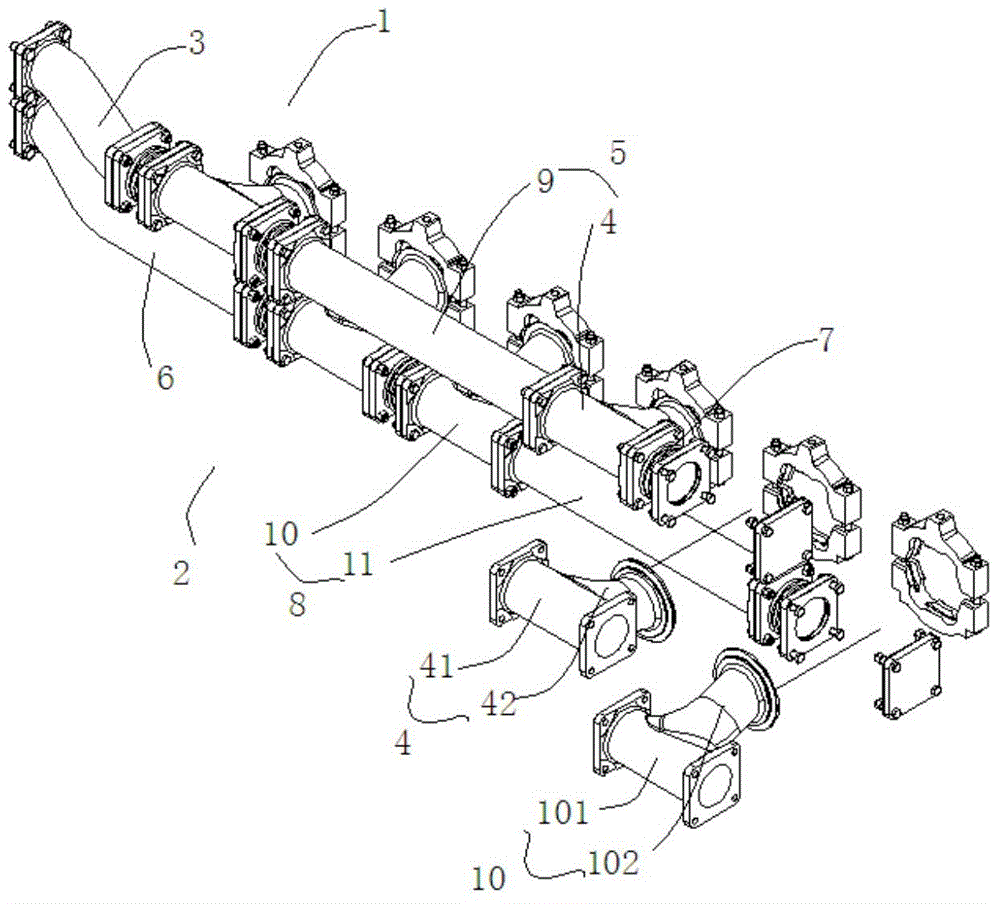

Multistage centrifugal pump delivery chamber

ActiveCN106762676AReduce axial sizeReduce casting difficultyPump componentsRadial flow pumpsEngineeringMechanical engineering

The invention relates to the field of fluid machines, and provides a multistage centrifugal pump delivery chamber which is small in axial size and easy to cast and assemble. The multistage centrifugal pump delivery chamber comprises a first annular runner, a diffusing section and a second annular runner located on the outer side of the first annular runner. The second annular runner is formed in the inner side of a shell and located at an outlet of a first final-stage guide vane. The areas of all sections of the second annular runner are equal. The first annular runner is formed by matching a rear cover plate of the first final-stage guide vane and a rear cover plate of a second final-stage guide vane. The diffusing section is in a horn shape, is located on one side of the second annular runner, and communicates with the second annular runner.

Owner:西安航天泵业有限公司

Engine exhaust pipeline structure

InactiveCN104533585AReduce casting difficultyImprove connection strengthExhaust apparatusSilencing apparatusModular designEngineering

The invention discloses an engine exhaust pipeline structure. The engine exhaust pipeline structure comprises a first exhaust pipe and a second exhaust pipe which are arranged side by side. The first exhaust pipe is formed by connecting a first inlet pipe, first module pipes and at least one first pipe set in sequence. The second exhaust pipe is formed by connecting a second inlet pipe and at least one second pipe set in sequence. The first inlet pipe, the first module pipe and the second inlet pipe are correspondingly arranged. The first pipe set and the second pipe set are correspondingly arranged. By means of the structure, the modular design is carried out on the first exhaust pipe and the second exhaust pipe, a segmented arrangement form of various cylinder exhaust pipes is presented, and the engine exhaust pipeline structure is simpler, more reasonable and more attractive in appearance. Meanwhile, the casting difficulty can be obviously lowered through the modular design of the cylinder exhaust pipes, the exhaust pipeline transition is smoother, the yield of castings is increased, and the assembling technology is improved.

Owner:CHONGQING PUSH MECHANISM

Sewage pump impeller with cutting function and sewage pump

ActiveCN110645200AEasy to replaceImproves tangle resistanceSpecific fluid pumpsPump componentsFiberImpeller

The invention relates to a sewage pump impeller with a cutting function and a sewage pump. The sewage pump impeller is designed as a semi-open type impeller with cylindrical blades. The casting and machining difficulty is reduced. The production cost is reduced. The risk of a long-fiber material wound around the impeller is reduced by reducing the wrap angle of the blades of the sewage pump impeller. Meanwhile, a cutting device is arranged at the front end of the impeller and can be used for cutting the long-fiber material and large-particle solid. Accordingly, the non-clogging performance ofthe sewage pump impeller is further improved. The designed cutting device is connected with the blades through screws, is convenient to replace and can achieve the protection effect on the impeller. The light and thin design of the cutting device has no influence on compactness and miniaturization of an original pump and has less influence on the open area. Cutting tools are provided with cuttingfaces in streamline transition and cannot cause rising of shaft power during working and have less disturbance on a flow field.

Owner:JIANGSU UNIV

Magnetic stirring type flow cytometry flowing chamber

ActiveCN105717036AWith initial velocityWill not blockIndividual particle analysisMagnetic tension forceMagnetic bead

The invention relates to a flowing chamber of a flow cytometry and particularly relates to a magnetic stirring type flow cytometry flowing chamber. The magnetic stirring type flow cytometry flowing chamber comprises a flowing chamber body, a sample feeding needle and a sheath liquid chamber, wherein the sample feeding needle penetrates through the flowing chamber body and the sheath liquid chamber; the sheath liquid chamber is located above the flowing chamber body and is connected with the flowing chamber body through a sheath liquid hole; the flowing chamber body is internally provided with a magnetic bead; an electromagnet is arranged between the flowing chamber body and the sheath liquid chamber; and a sheath liquid inlet is formed at the upper end of the sheath liquid chamber. The magnetic stirring type flow cytometry flowing chamber can be used for rapidly stabilizing a laminar flow and saving energy sources. The sheath liquid still has a centripetal force when the sheath liquid is sprayed out from a nozzle; and the sample feeding needle is located at the circle center and is located at the position of a typhoon eye, so that the sample feeding needle can fall off in a straight line, is not mixed with the sheath liquid and does not block the nozzle.

Owner:ANHUI NORMAL UNIV

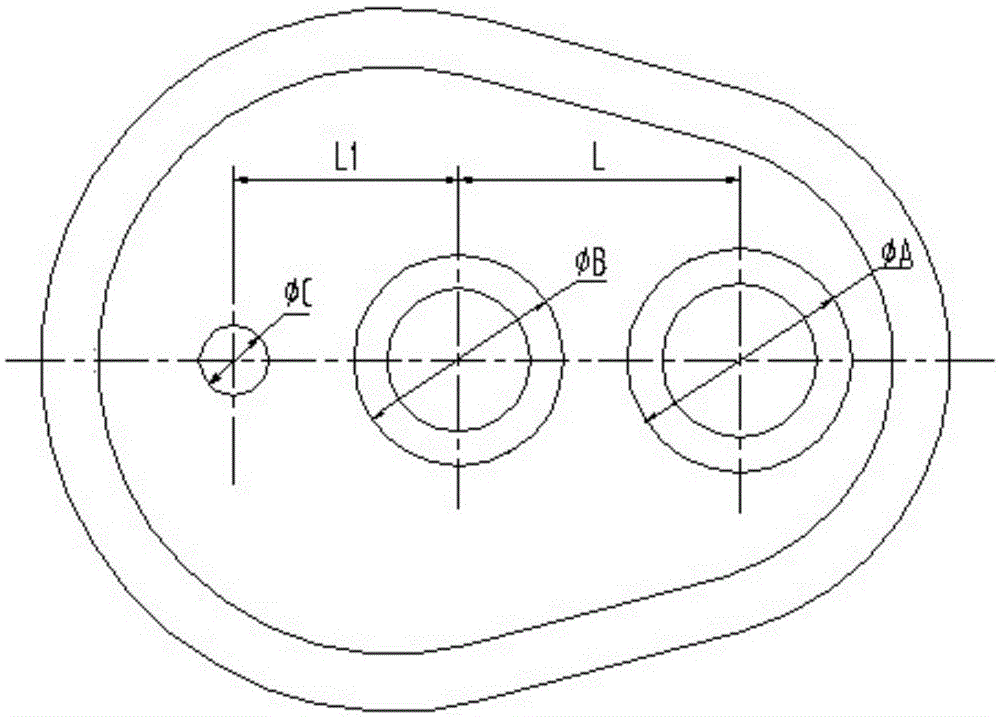

Machining method for box cover of gearbox

The invention discloses a machining method for a box cover of a gearbox which can reduce the machining time, lower the machining cost, and improve the product quality. The machining method comprises the following steps: step (1) casting the box cover and forming a high-speed shaft hole phi A and a low-speed shaft hole phi B in the box cover; step (2) ensuring a center distance L between the high-speed shaft hole phi A and the low-speed shaft hole phi B, and finish machining the high-speed shaft hole phi A and the low-speed shaft hole phi B; and step (3) ensuring a center distance L1 between the low-speed shaft hole phi B and a gear pump hole phi C, drilling the gear pump hole phi C, and then boring the gear pump hole phi C.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com