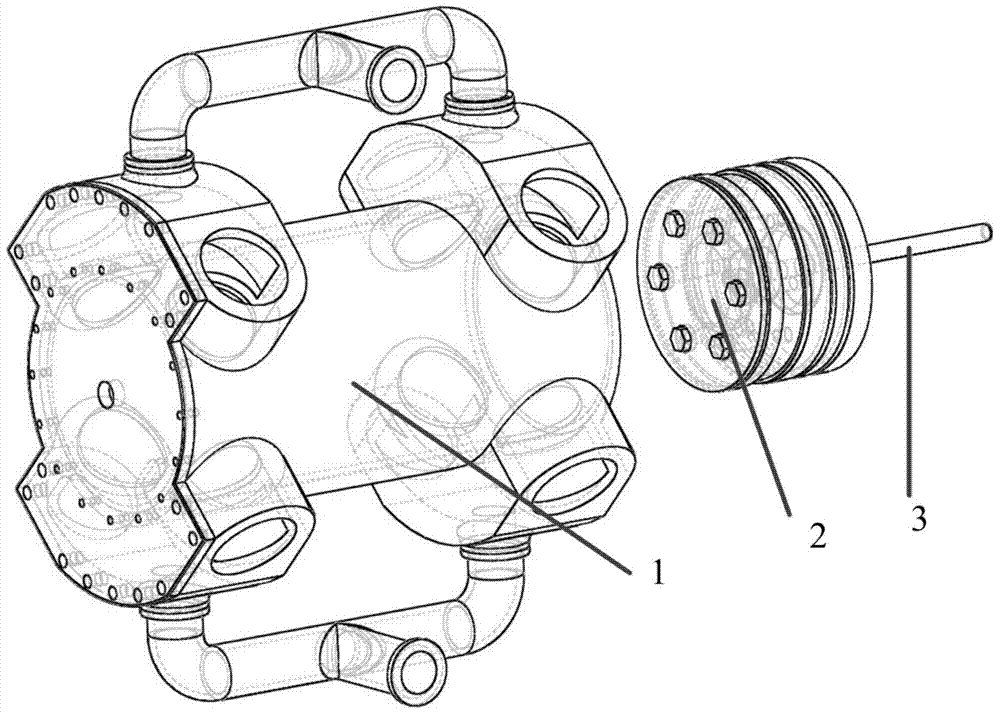

Low-temperature air cylinder working chamber component structure of liquefied natural gas vapor compressor

A technology of liquefied natural gas and component structure, which is applied in the field of compressors, can solve problems such as poor casting performance, and achieve the effects of simple casting, good sealing and movement performance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

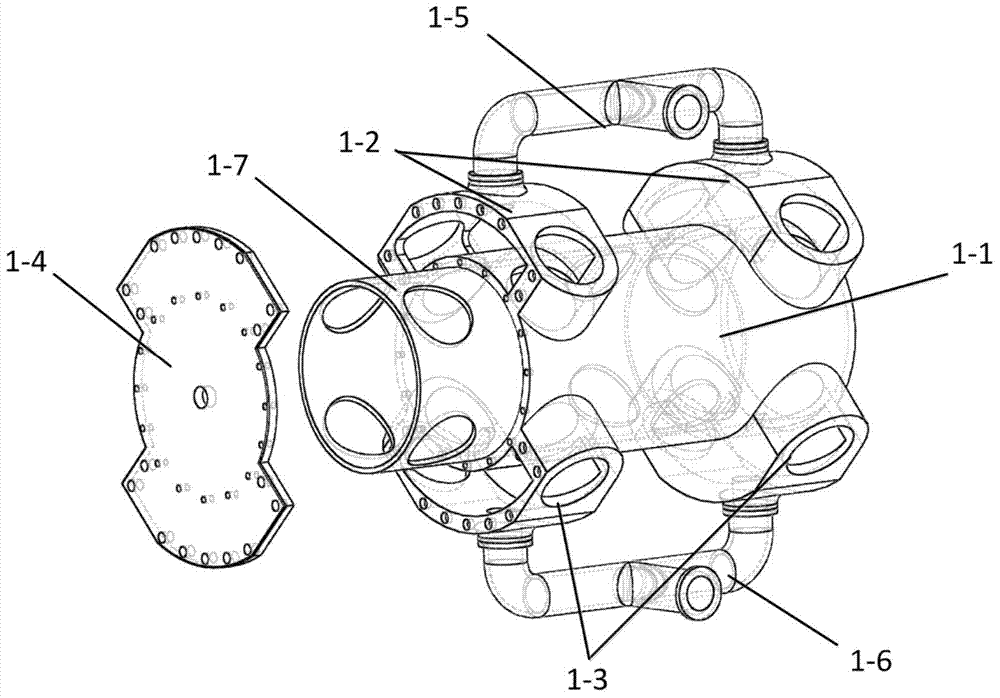

[0028] figure 2 Shown is an integrated cast cylinder structure. The cylinder block 1-1, intake valve chamber 1-2 and exhaust valve chamber 1-3 are cast in one piece. The upper part of the cylinder is the intake valve chamber and the lower part is the exhaust valve chamber. There are 8 in total. The two valve chambers share one inlet and exhaust passage, one side of the crankshaft is closed, the other end is half open for casting, and the opening is sealed by end caps 1-4. The front-end valve chamber is milled out of a plane after the casting is completed, and a screw hole is opened on the plane, and the end cover 1-4 is fastened with bolts. The intake valve chamber 1-2 and the exhaust valve chamber 1-3 are provided with flanges that can be connected with flanges, and the flanges are respectively connected to the flanges of the intake air collecting pipe 1-5 and the exhaust collecting air pipe 1-6 through bolts. Connected. The intake collecting air pipes 1-5 and the exhaust c...

Embodiment 2

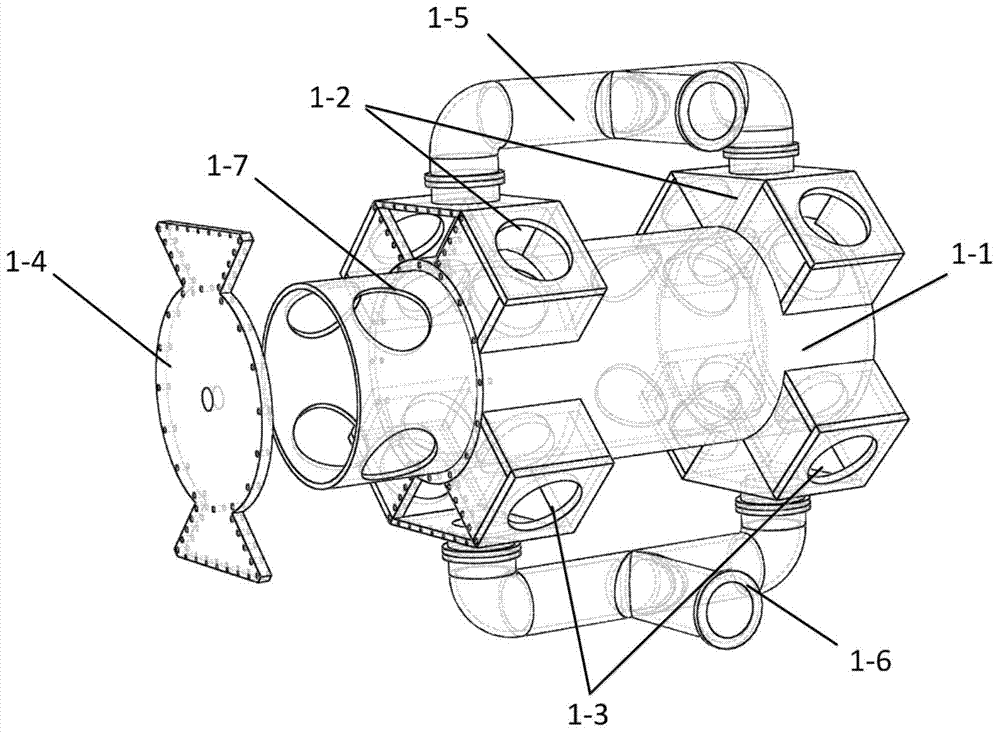

[0030] Such as image 3 As shown, the difference from Embodiment 1 is that the cylinder block 1-1, the intake valve chamber 1-2 and the exhaust valve chamber 1-3 of this embodiment are manufactured separately and connected by welding. The cylinder block 1-1 is only a cylindrical cavity, and the intake valve chamber 1-2 and the exhaust valve chamber 1-3 are respectively formed by welding several steel plates. The shape of the assembled valve housing is a rectangular parallelepiped with cylindrical valve holes. The rest of the arrangement is similar to the first embodiment, one side of the crankshaft is closed, the other end is half open for casting, and the opening is sealed by the end caps 1-4. Since the outer walls of the intake valve chamber 1-2 and the exhaust valve chamber 1-3 are flat, several threads can be directly opened on the outer walls of the cylinder block 1-1, intake valve chamber 1-2 and exhaust valve chamber 1-3 Holes are connected with end caps 1-4 by bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com