Machining method for box cover of gearbox

A processing method and gear box technology, applied in the field of mechanical processing, can solve the problems of large eccentric processing amount of drill bit, uncorrectable drill bit, and increased processing time, so as to achieve the effects of reducing processing cost, easy control of position degree, and reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A method for processing a gearbox case cover, comprising the following steps:

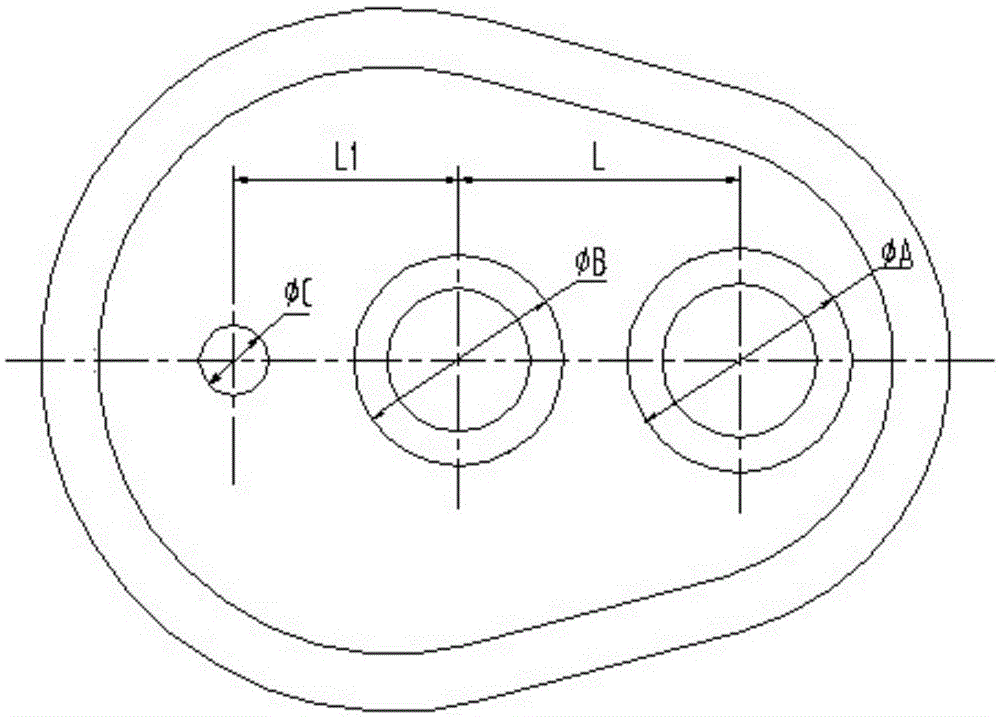

[0031] Step 1) Use GGG40 to cast the box cover, and form the high-speed shaft hole ΦA and the low-speed shaft hole ΦB on the box cover by placing a mud core;

[0032] Step 2) Ensure the center distance L between the high-speed shaft hole ΦA and the low-speed shaft hole ΦB, ensure the coaxiality between the high-speed shaft hole ΦA on the gearbox cover and the high-speed shaft hole on the gearbox body, and ensure that the gear box The coaxiality of the low-speed shaft hole ΦB on the cover and the low-speed shaft hole on the gear box body, the high-speed shaft hole ΦA and the low-speed shaft hole ΦB are finished; in this embodiment, the high-speed shaft hole ΦA and the low-speed shaft hole ΦB The finishing method is boring.

[0033] Step 3) The processing method of the high-speed shaft hole ΦA and the low-speed shaft hole ΦB also adopts a combined processing method for the box body and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com