Ammoxidation furnace formed by novel platinum net brace that is catalyst basket and support structure thereof

A catalyst basket and support structure technology, applied in the directions of nitrogen oxides/oxyacids, nitric acid, etc., can solve the problems of uncoordinated deformation, damage, cracking of welded structures, etc., to avoid heat loss, ingenious design, and reduce maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

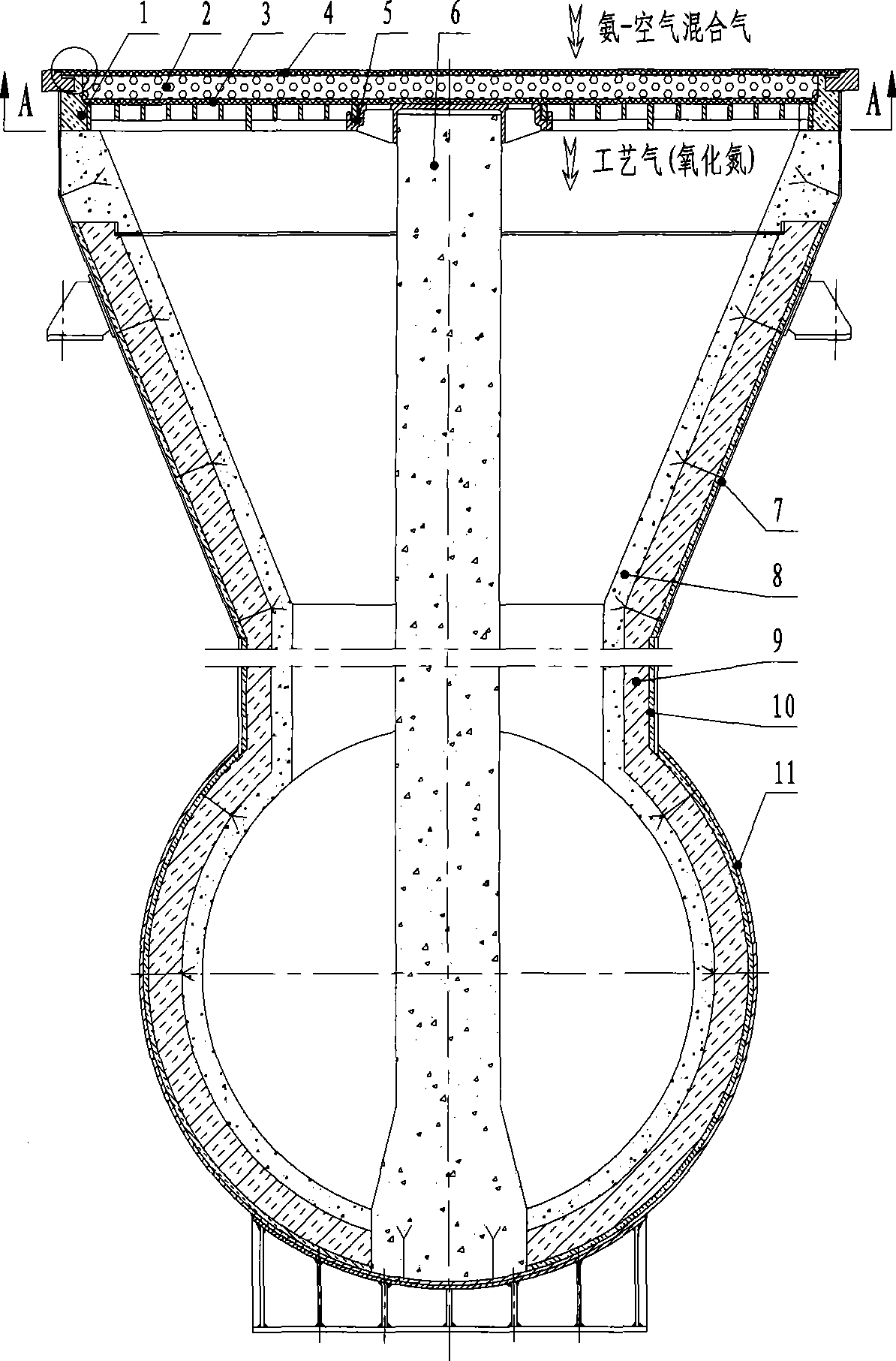

[0018] Embodiment 1: with reference to attached figure 1 , Picture 1-1 , image 3 . The ammonia oxidation furnace consists of a new platinum mesh bracket and its supporting structure. It includes an oxidation furnace. A wire mesh is placed on the bracket to form a catalyst basket. Thermally heavy concrete columns are supported, CDM catalysts are loaded on wire mesh, and platinum meshes are placed on the CDM catalysts.

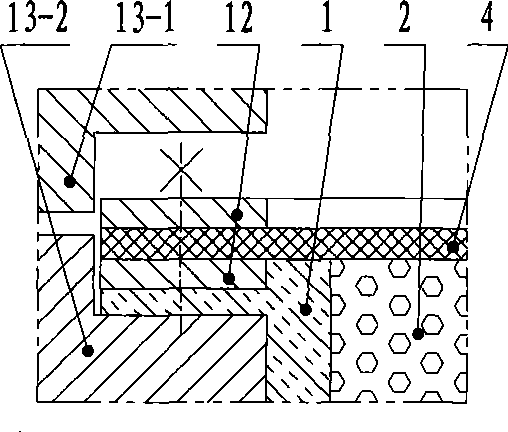

[0019] figure 1 It shows the ammonium oxidation furnace of nitric acid plant composed of type I platinum mesh bracket, catalyst basket and supporting structure. It includes: an oxidation furnace shell 7 and a heavy refractory concrete column 6 erected in the center of the front tube box 11 of the waste pot, and the lower end of the concrete column 6 is poured on the bottom of the front tube box 11 of the waste pot, the center disc of the upper support bracket 5, and The outer ring of the fan-shaped part of the frame 5 is supported on the heavy refractory ...

Embodiment 2

[0020] Embodiment 2: with reference to attached Figure 4 , Pic 4-1 , Figure 6 . Figure 4 It shows the ammonia oxidation furnace composed of type II platinum mesh bracket and catalyst basket, which is suitable for the oxidation furnace whose diameter is smaller than that of embodiment 1; On the heavy refractory concrete 8—the heavy concrete 8 here bears all the loads generated by the self-weight of the bracket 5 and the CDM catalyst 2 and the bed resistance of the CDM catalyst 2; no concrete column 6 is set; the rest are the same as in Example 1 same.

Embodiment 3

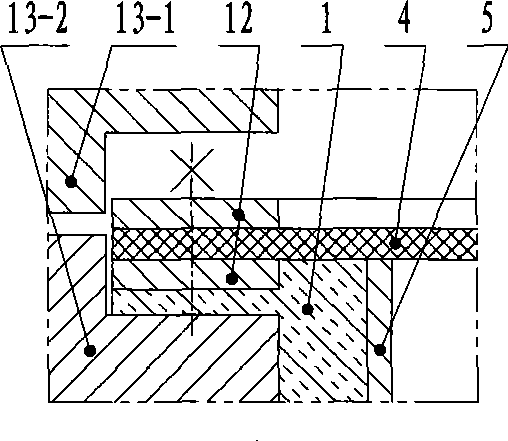

[0021] Embodiment 3: with reference to attached Figure 7 , an ammonia oxidation furnace composed of a type III platinum mesh bracket and a catalyst basket, suitable for an oxidation furnace with a smaller diameter than that of Example 2; the bracket 5 is integrally cast, and its outer ring is supported on the lower flange 13-2 of the oxidation furnace Above, the lower flange 13-2 bears all the loads generated by the self-weight of the bracket 5 and the CDM catalyst 2 and the bed resistance of the CDM catalyst 2; the rest is similar to that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com