Manufacturing method of curved-surface touch screen glass cover plate

A curved touch screen and glass cover technology, which is applied in glass manufacturing equipment, glass production, glass cutting devices, etc., can solve the problems of high technical requirements, high cost, and low yield rate, so as to reduce the difficulty of the process, improve work efficiency, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a method for manufacturing a curved touch screen glass cover, comprising the following steps:

[0023] a) To clean the glass substrate, select several pieces of soda-lime glass with a size of 650mm*550mm and a glass thickness of 0.6mm, and wash them in a cleaning agent solution with a mass concentration of 15% to 25% for 30 minutes to remove impurities on the surface of the glass substrate. stains;

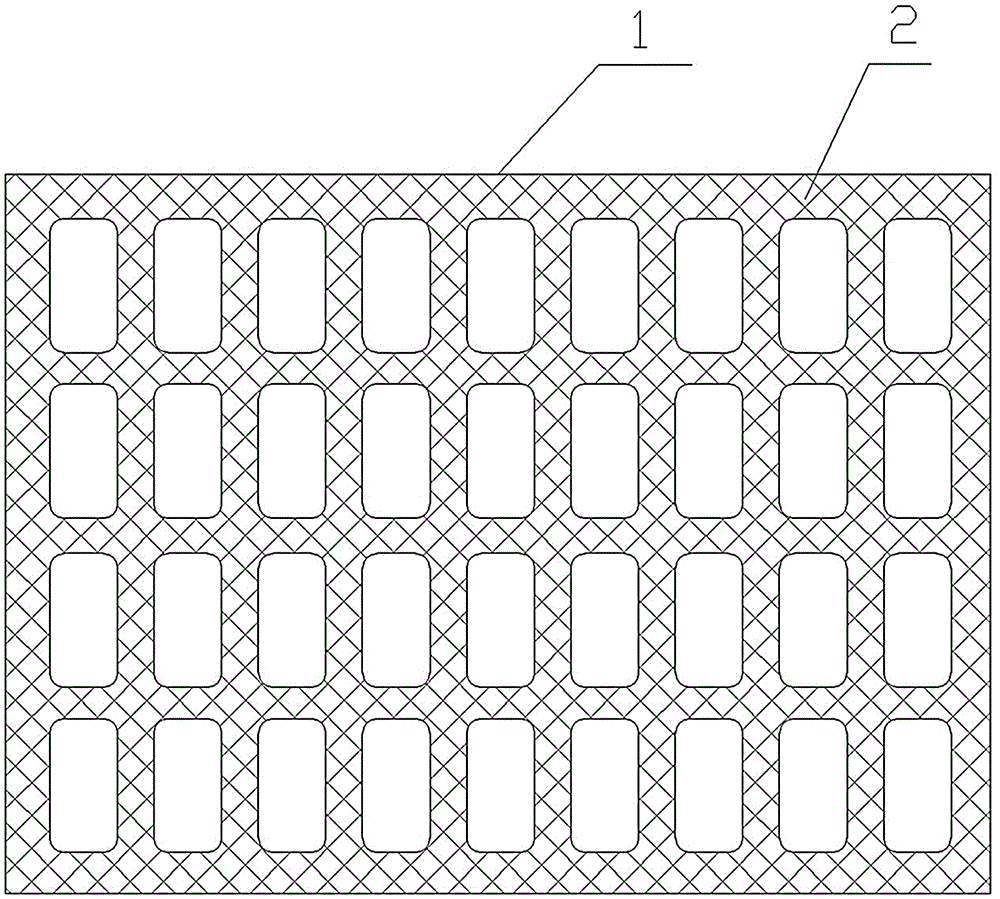

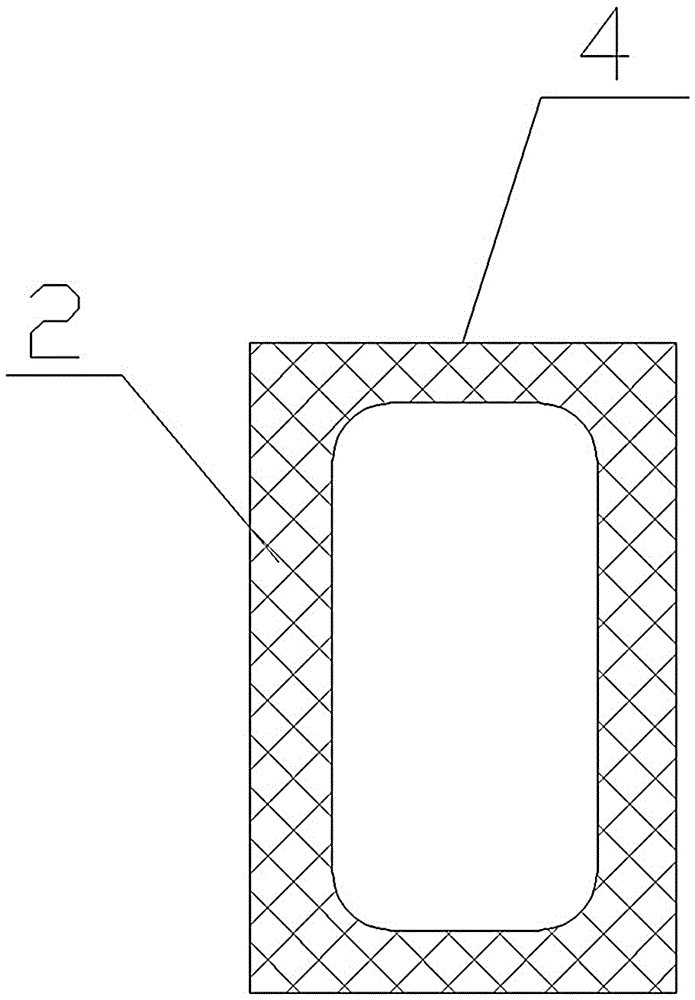

[0024] b) if figure 1 As shown, the glass substrate 1 is divided into a group of touch screen glass cover plates according to the outline of the touch screen, and acid-resistant ink 2 is screen-printed on one side of the glass substrate 1, and the acid-resistant ink 2 is distributed on each touch screen glass cover plate around the edge;

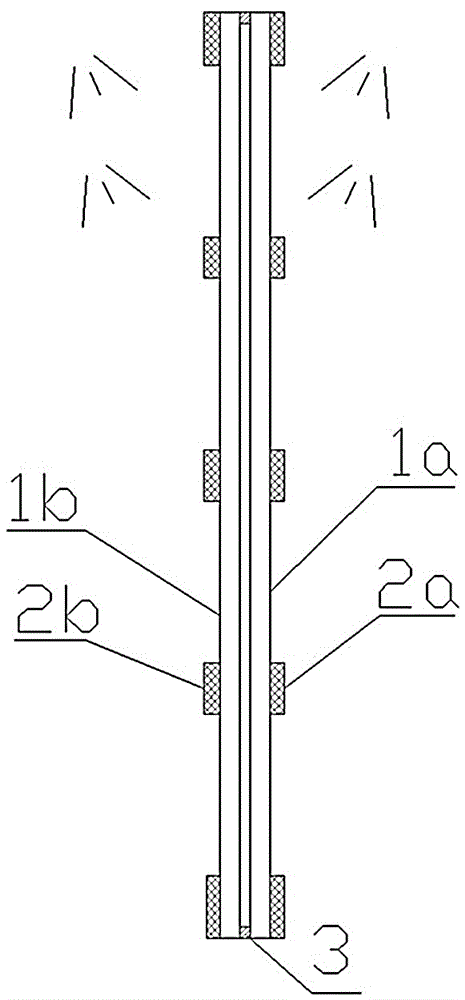

[0025] c) Single-sided etching of the glass substrate using single-sided thinning technology, combined with figure 2 As shown, select two screen-printed glass substrates, the first glass substrate 1a and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com