A design method of guide vane of submersible axial flow pump and guide vane of submersible axial flow pump

A design method and technology for an axial flow pump, which are applied to the components, pumps, and pump components of a pumping device for elastic fluids, which can solve the problem of inappropriate use of submersible axial flow pump guide vanes, unfavorable long-term stable operation of the pump, and increased casting. Difficulty and other problems, to achieve the effect of saving manpower, increasing strength, and reducing casting difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to illustrate the technical solution of the present invention more clearly, further detailed description will be given below in conjunction with the accompanying drawings along with the present invention.

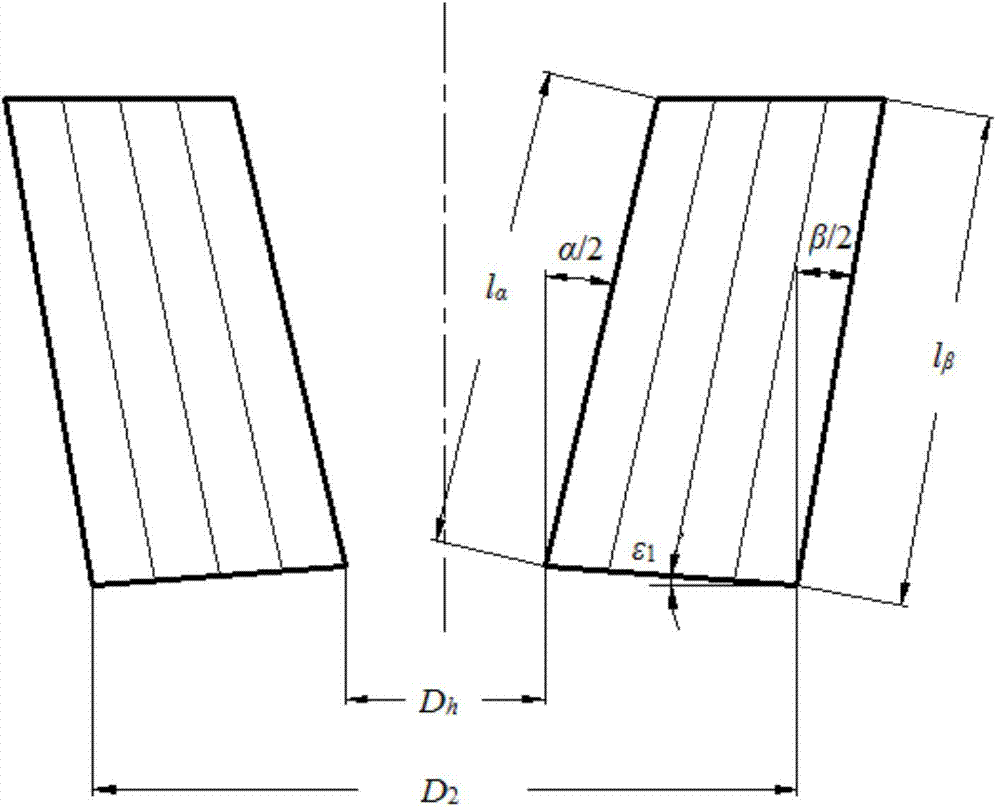

[0043] Such as figure 1 As shown, the structural parameters of the guide vane of the submersible axial flow pump mainly include the diameter of the hub of the inlet guide vane D h , Outer diameter of inlet guide vane D 2 , guide vane inlet inclination angle ε 1 , 1 / 2 guide vane inner divergence angle α / 2, 1 / 2 guide vane outer divergence angle β / 2, guide vane inner streamline length l α , guide vane outer flowline length l β .

[0044] The guide vane design method of the submersible axial flow pump described in the present invention is based on the diameter of the submersible axial flow pump impeller hub and the outer diameter of the impeller to determine the diameter D of the inlet guide vane hub h , Outer diameter of inlet guide vane D 2 , Guide vane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com