Rotation paddle type water turbine paddle operation mechanism

A technology of operating mechanism and water turbine, which is applied in the direction of machine/engine, reaction engine, hydroelectric power generation, etc., can solve the problems of inability to complete the design of the propeller mechanism, poor casting, poor processing technology, and impact on the reliability of connecting parts, etc. Ingenious structural design, compact structure, and the effect of improving operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

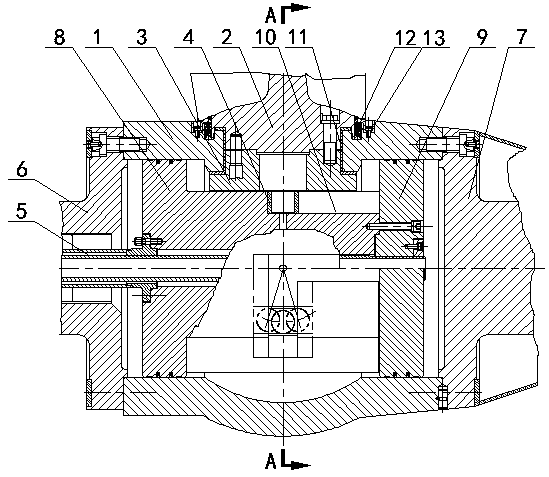

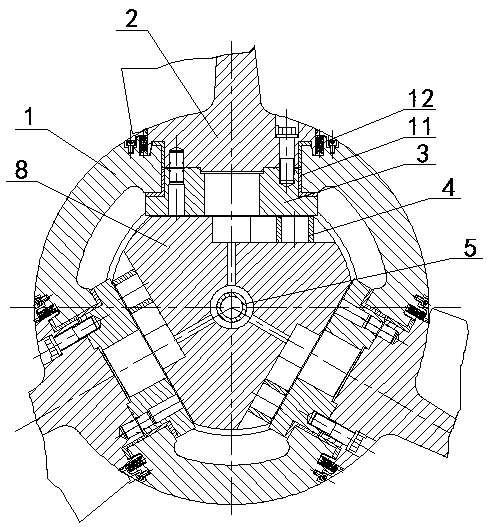

[0025] Embodiment 1: as figure 1 , 2 As shown, a paddle type water turbine blade operating mechanism includes a runner body 1, on which at least three blades 2 are arranged, and in the runner body 1 is provided a The rocker arm 3 is provided with a piston mechanism with a slider 4 at the center of the runner body 1, the slider 4 is connected with the rocker arm 3, and an operating oil pipe 5 is arranged at the center of the piston mechanism. Both ends of the piston mechanism are provided with a short shaft 6 and a main shaft 7 respectively connected to the runner body 1 .

[0026] Wherein, the piston mechanism includes a piston groove body 8, the slider 4 is arranged on the piston groove body 8, and a right piston 9 connected with the piston groove body 8 is arranged on the right side of the piston groove body 8. The main shaft 7 is arranged outside the right piston 9 .

[0027] To further describe, a sliding groove 10 is provided on the outer wall of the piston tank body 8...

Embodiment 2

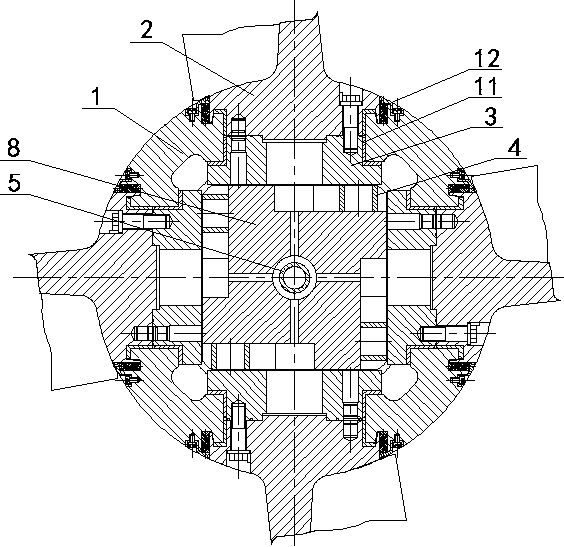

[0030] Embodiment 2: as image 3 As shown, in this embodiment, the piston tank 8 is square, and four slide grooves 10 are evenly arranged on the piston tank 8; the number of the sliders 4 is four, and the four sliders 4 are respectively Located in four sliding slots 10; the sliding slots 10 are respectively connected with corresponding rocker arms 3 through pins.

[0031] In the present invention, one is that the connecting rod is no longer needed; the other is that the axial stroke of the slider 4 is the sine value of the center radius corner of the pin on the rocker arm, and the radial stroke is a cosine value, and the general blade 2 corners will not Over 36°, the sine value of the axial travel will be much greater than the cosine value of the radial travel. The axial space is relatively large; while the radial stroke is small, the required movement space is also small, and the radius of the rocker arm 3 can be appropriately increased in the limited space——the force arm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com