Six-gear single-middle-shaft transmission

A single intermediate shaft and transmission technology, applied in the direction of instruments, controlled components, mechanical control devices, etc., can solve the problems of large external dimensions, low bearing capacity, incompatibility, etc. The effect of casting difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

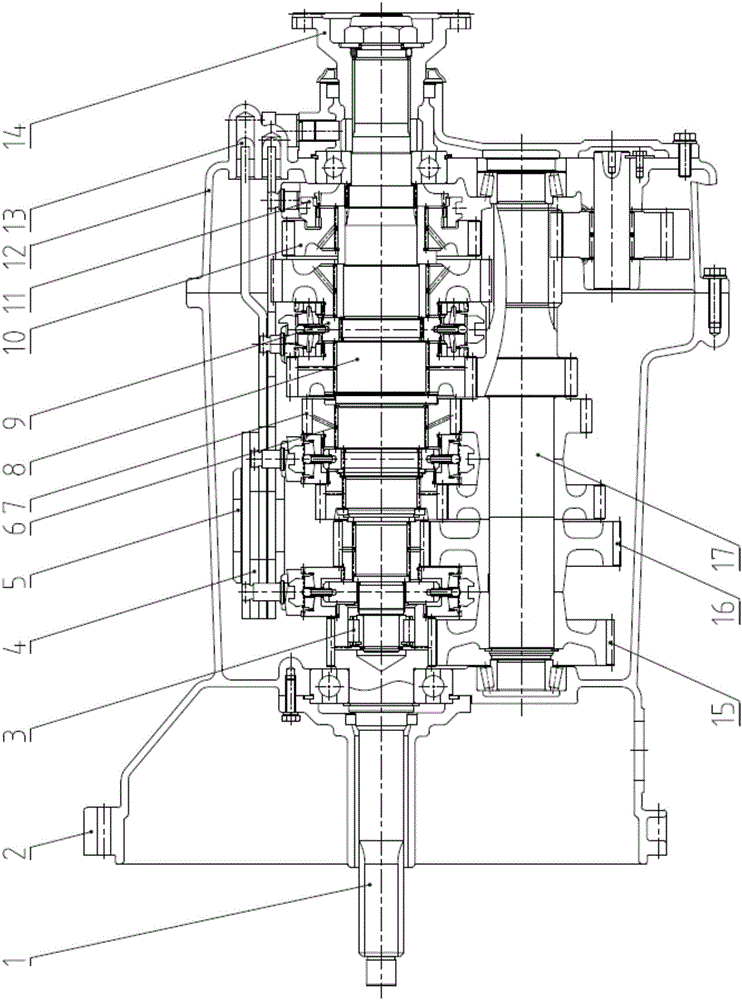

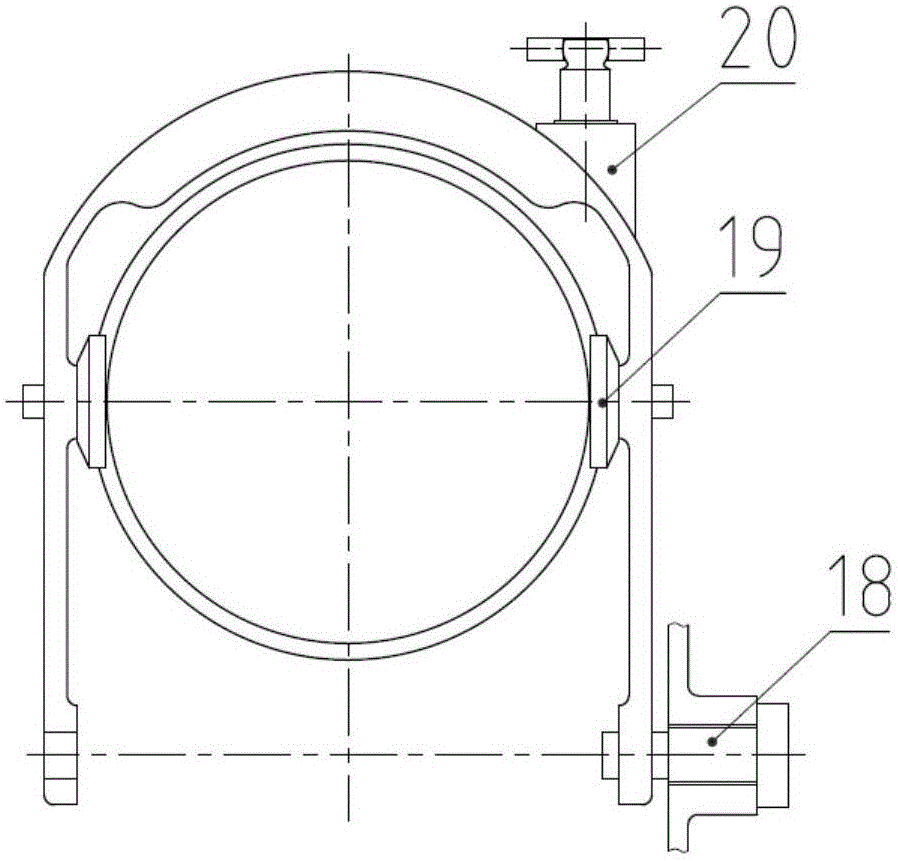

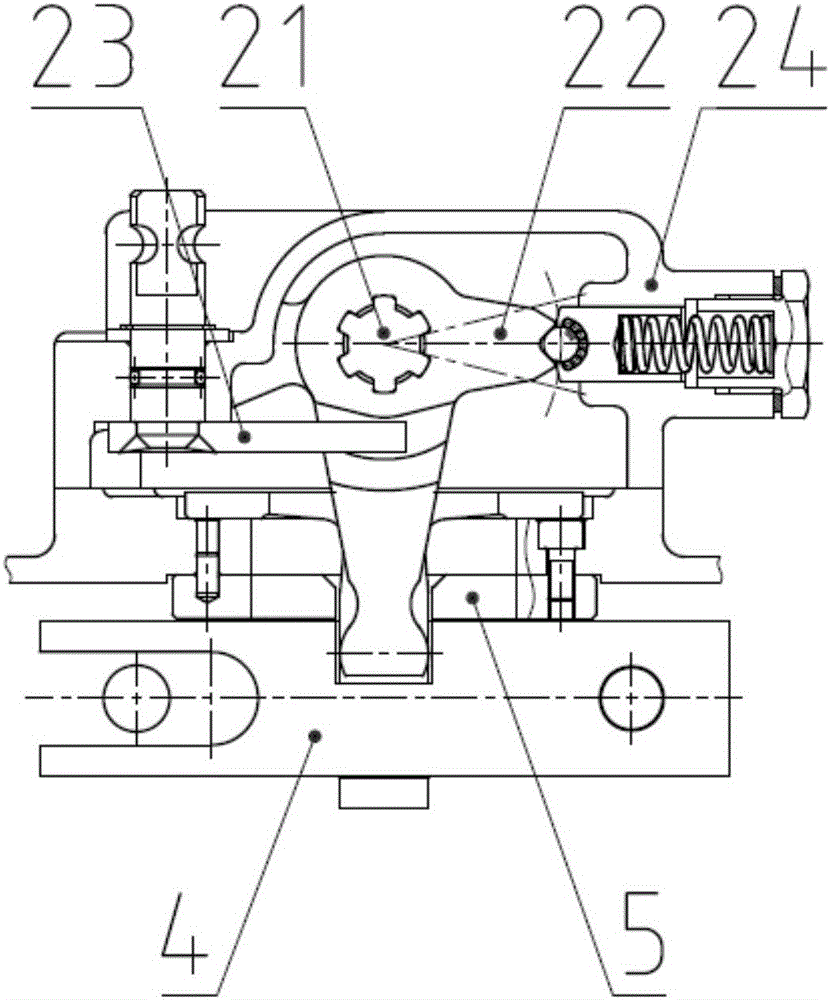

[0040] see figure 1 and figure 2 The transmission casing of the present invention includes two sections of the front casing 2 and the rear casing 12 connected together, which are "tube-type" structures; The transmission is lightweight. In the cavity formed by the front housing 2 and the rear housing 12, an intermediate shaft 17 and an input shaft 1 integrated with an input gear are provided. The main shaft 8 is installed above the shaft 17, and the counter shaft gear 16 on the counter shaft 17 is in constant mesh with the main shaft gear 7 on the main shaft 8 respectively, and the counter shaft transmission gear 15, the counter shaft gear 16 and the counter shaft 17 are all used Ying connection, and the "shrink-fitting method" is used for assembly; the rear end of the main shaft 8 is connected to the output flange 14.

[0041]The main shaft gear 7 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com