Small-sized six-axis linkage knife grinding device

A technology of six-axis linkage and sharpening device, applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc. And the efficiency of machining and low use efficiency, etc., to achieve the effect of compact structure, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

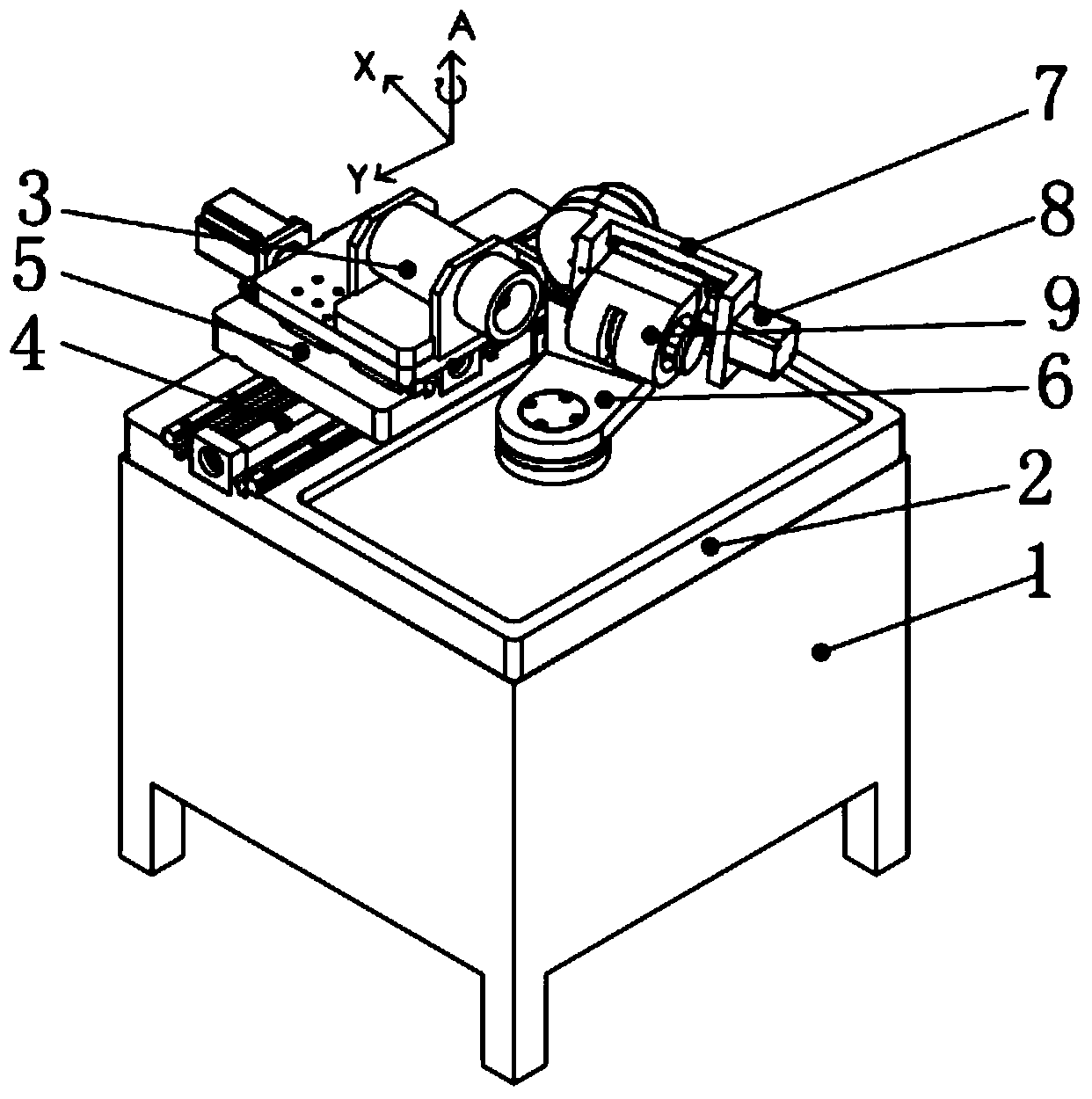

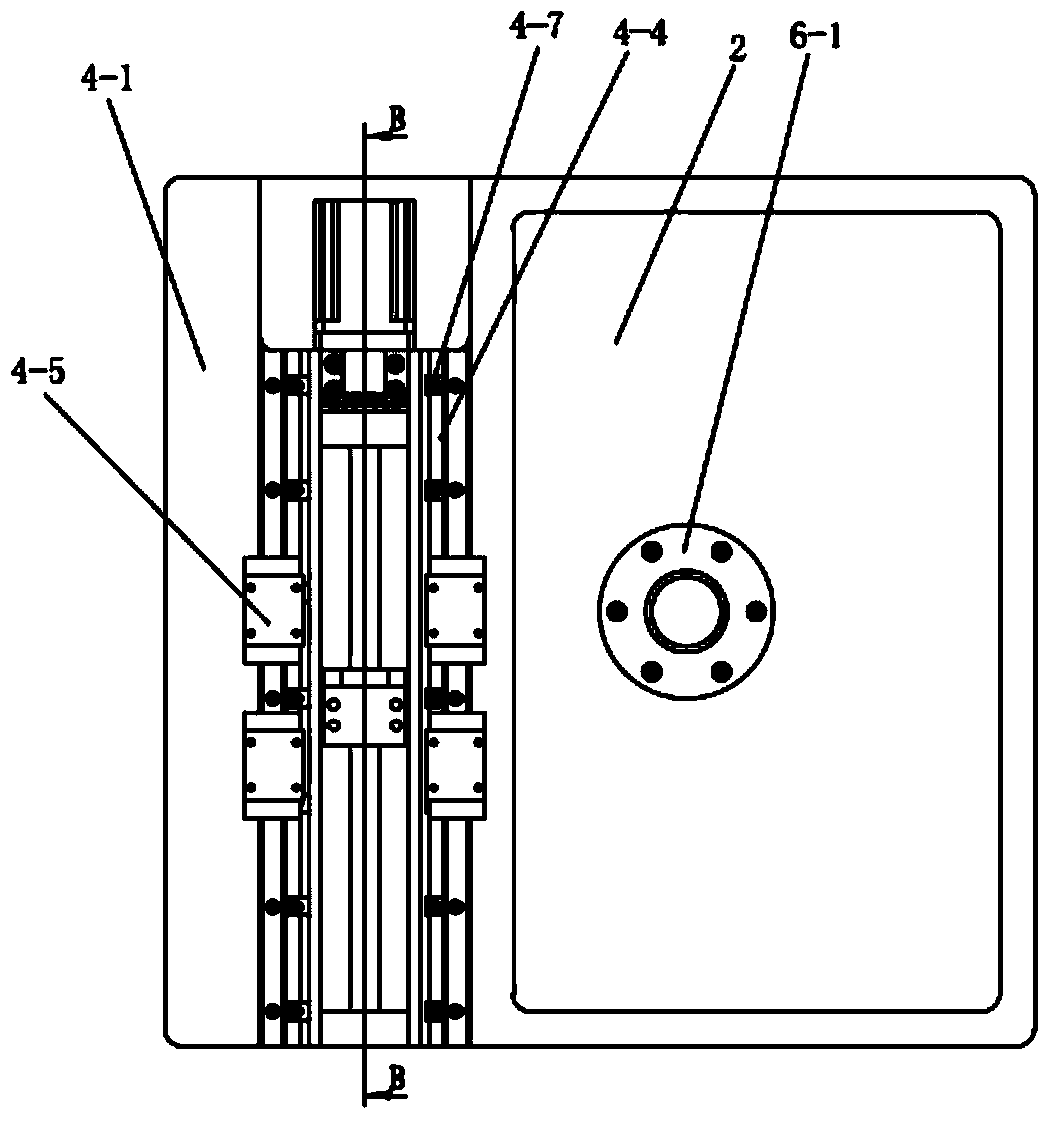

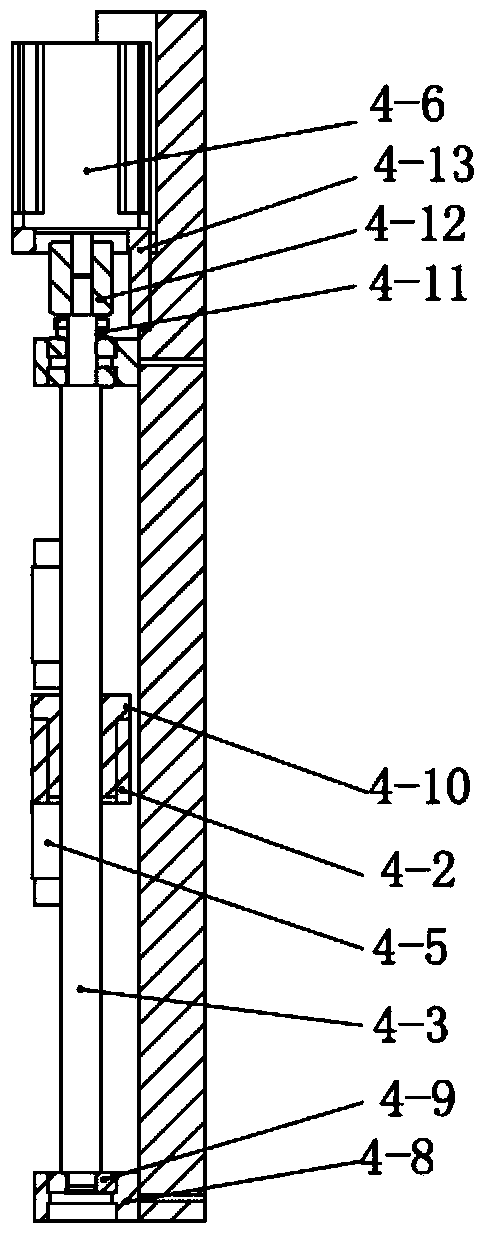

[0038] Such as figure 1 As shown, the present embodiment includes a small frame 1 and a bed 2 arranged on the small frame 1. A sharpener 3 and a six-axis linkage mechanism are arranged on the bed 2. The six-axis linkage mechanism is composed of a Y-axis moving mechanism 4. X-axis moving mechanism 5, Z-axis moving mechanism 8, A-axis rotating mechanism 6, B-axis rotating mechanism 7 and C-axis rotating mechanism 9; Y-axis moving mechanism 4, X-axis moving mechanism 5 and knife sharpener 3 are movable Connected, the X-axis moving mechanism 5 drives the knife sharpener 3 to move linearly along the X-axis, and the Y-axis moving mechanism 4 drives the knife sharpener 3 to move linearly along the Y-axis, and the Y-axis moving mechanism 4 and the X-axis moving mechanism 5 move vertically , a tool installation unit is provided on the C-axis rotating mechanism 9, the A-axis rotating mechanism 6 drives the B-axis rotating mechanism 7 to rotate around the A-axis, the B-axis rotating mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com