Car frame connecting piece for electric car, car frame assembly and electric car

A technology for electric vehicles and connectors, which is applied in the field of parts connection, can solve the problems such as the inability to design additional floors, achieve the effects of easy processing and wide application, improve collision safety performance, and enhance connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

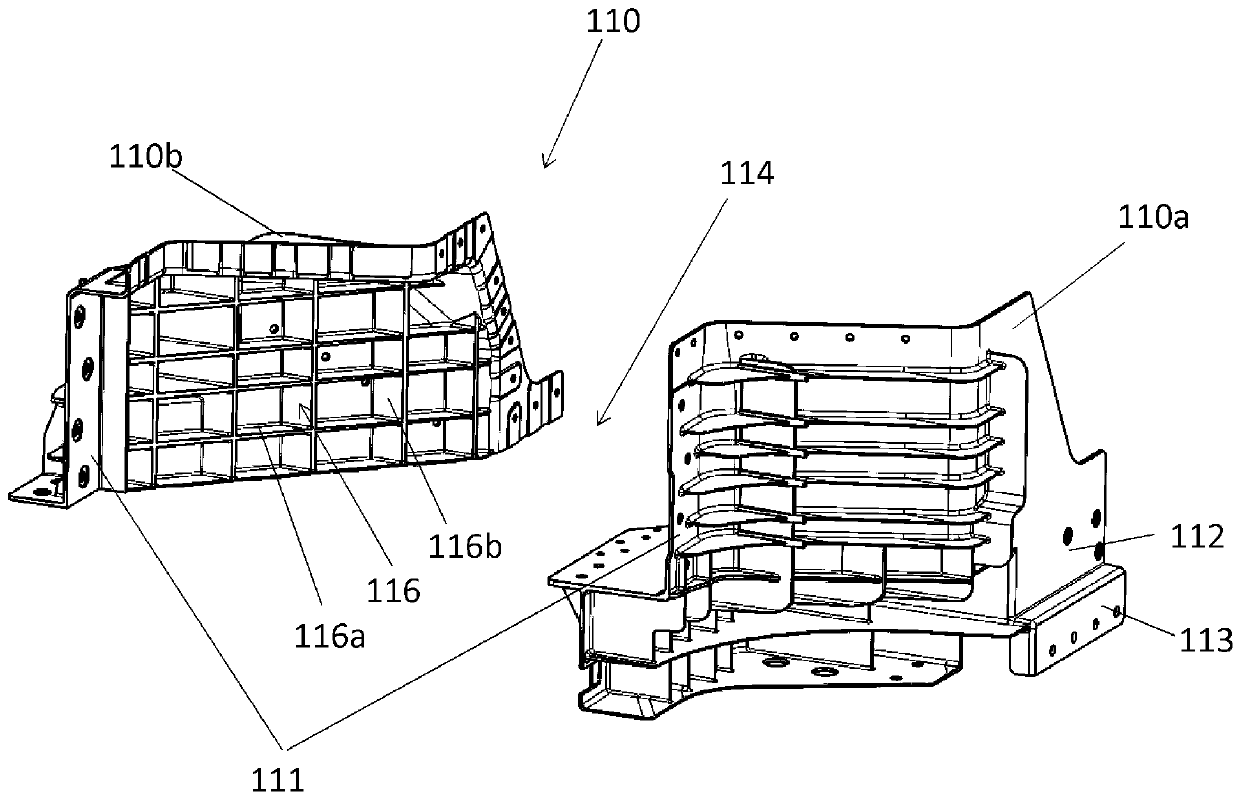

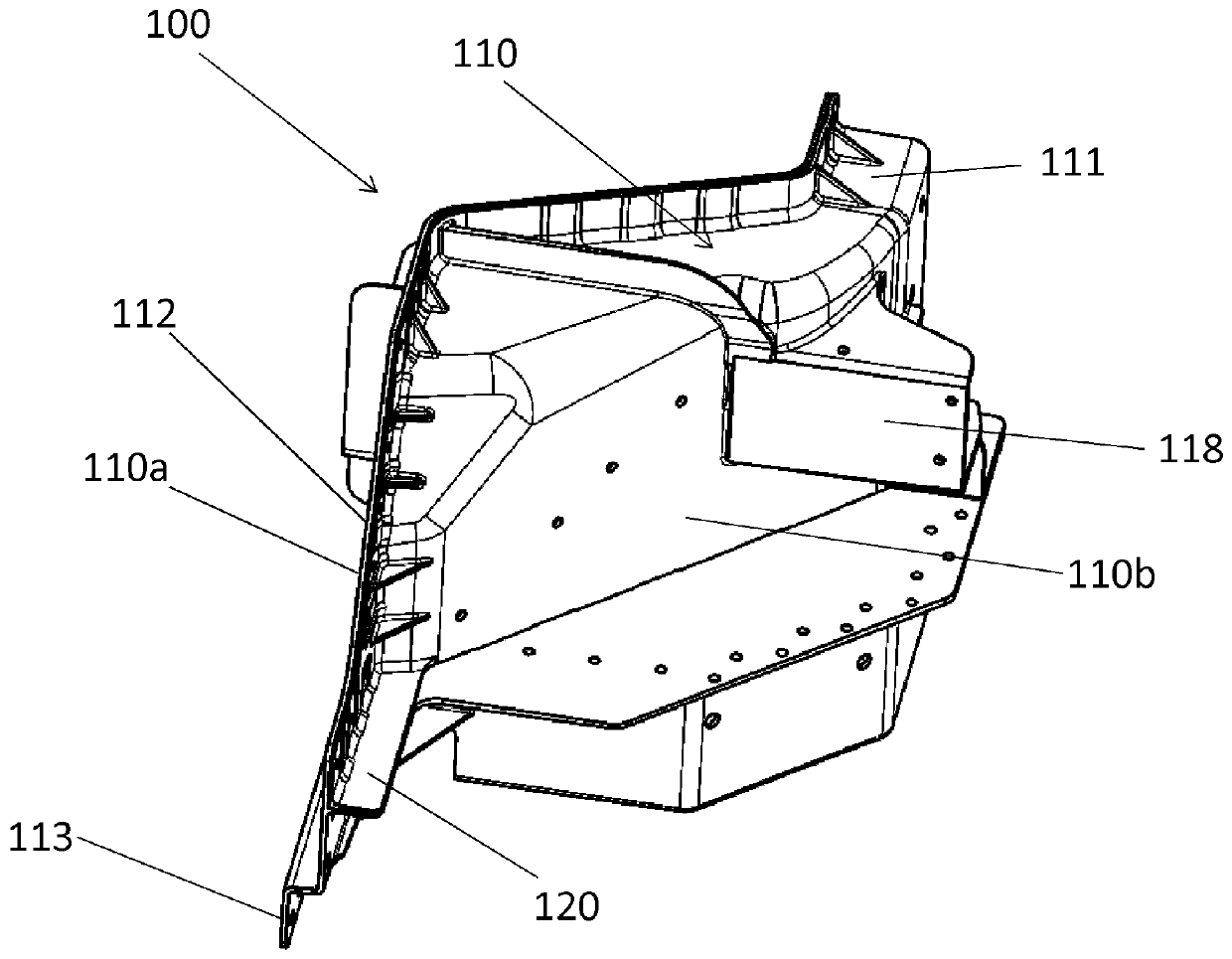

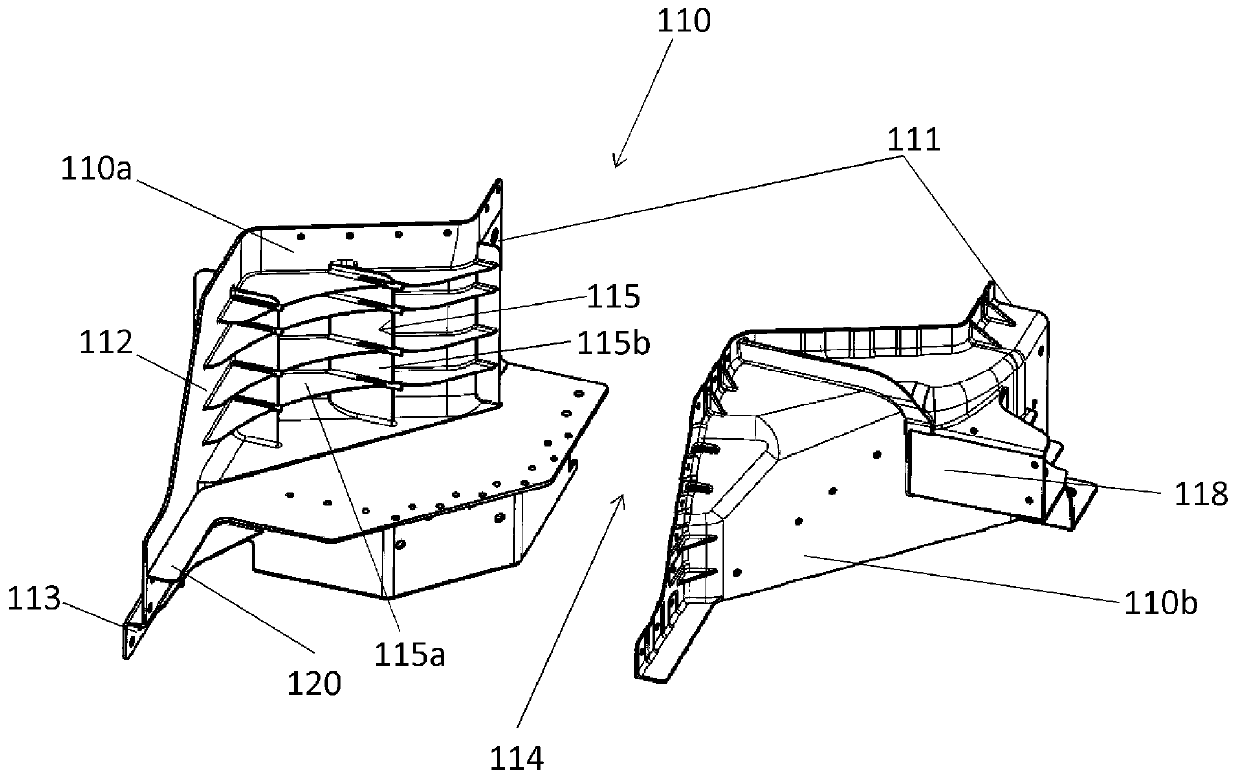

[0022] see Figure 1a-1b and Figure 2a-2c , which shows an embodiment of a frame connector 100 for an electric vehicle. The frame connector 100 of the electric vehicle includes a connector base 110 as a basis for receiving various frame parts and realizing transmission and dispersion of collision energy. In order to realize the aforementioned functions, the connector base 110 should at least have a front side beam connection part 111, an A-pillar lower inner panel connection part 112 and a door sill side beam connection part 113, which are used to connect the front side beam 200 and the A-pillar lower inner panel respectively. panel 400 and rocker stringer 300 . Considering the conventional location of these frame components in the frame arrangement, the front side member attachment section 111 can be positioned forward of the attachment base 110 and the A-pillar lower inner panel attachment section 112 when oriented along the frame. The sill rail connecting portion 113 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com