Axial pump vane airfoil optimizing design method

An optimized design and axial flow pump technology, which is applied to parts, pumps, and pump elements of pumping devices used for elastic fluids, and can solve the problem of reducing the service life of the guide vane, reducing the strength of the guide vane, and increasing the difficulty of casting the guide vane, etc. problems, to achieve the effect of reducing casting difficulty, improving head and efficiency, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

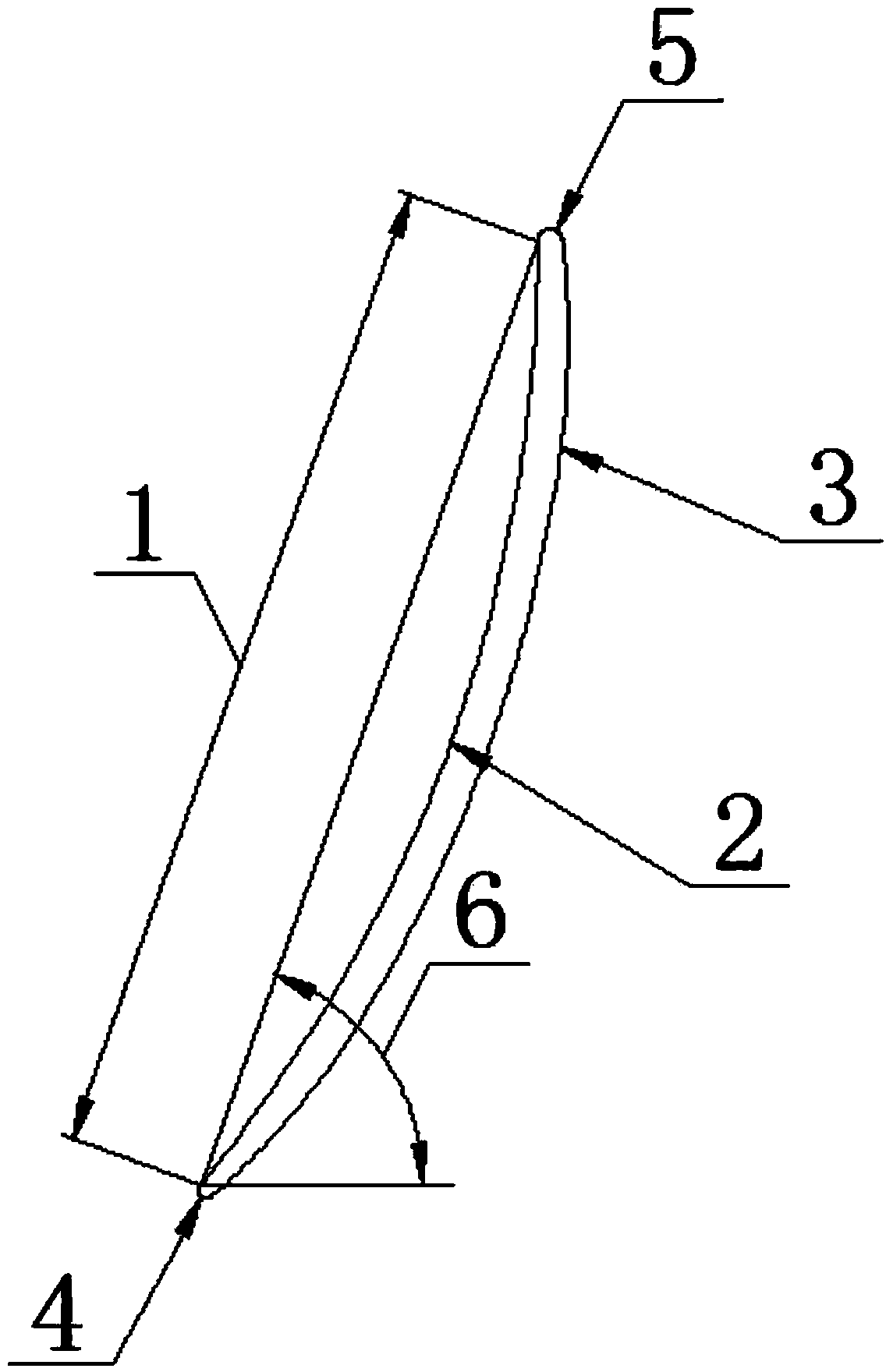

[0028] figure 1 The shape of the guide vane airfoil is determined for this embodiment. In the figure, first calculate the working surface profile radius R 1 (2) and back profile radius R 2 (3), then the sharp parts at both ends of the inlet and outlet of the guide vane airfoil are changed to a circular arc transition, and the arc radius of the guide vane inlet is r 1 (4) and guide vane outlet arc radius r 2 (5) Make sure that the thickness near the inlet and outlet ends is also appropriately thickened. The chord length l(1) and profile placement angle α are obtained by calculation L (6), using the molded line placement angle α L (6) Instead of the placement angle of the guide vane inlet and outlet, determine the placement position of the guide vane.

[0029] The guide vane airfoil is designed according to the following main parameters, including the chord length l(1) and the working surface profile radius R 1 (2), back profile radius R 2 (3), guide vane inlet arc radiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com