Product state detection method and system based on Adaboost algorithm

A state detection and product technology, applied in computing, computer parts, character and pattern recognition, etc., can solve problems such as low efficiency, increased human and material resources, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

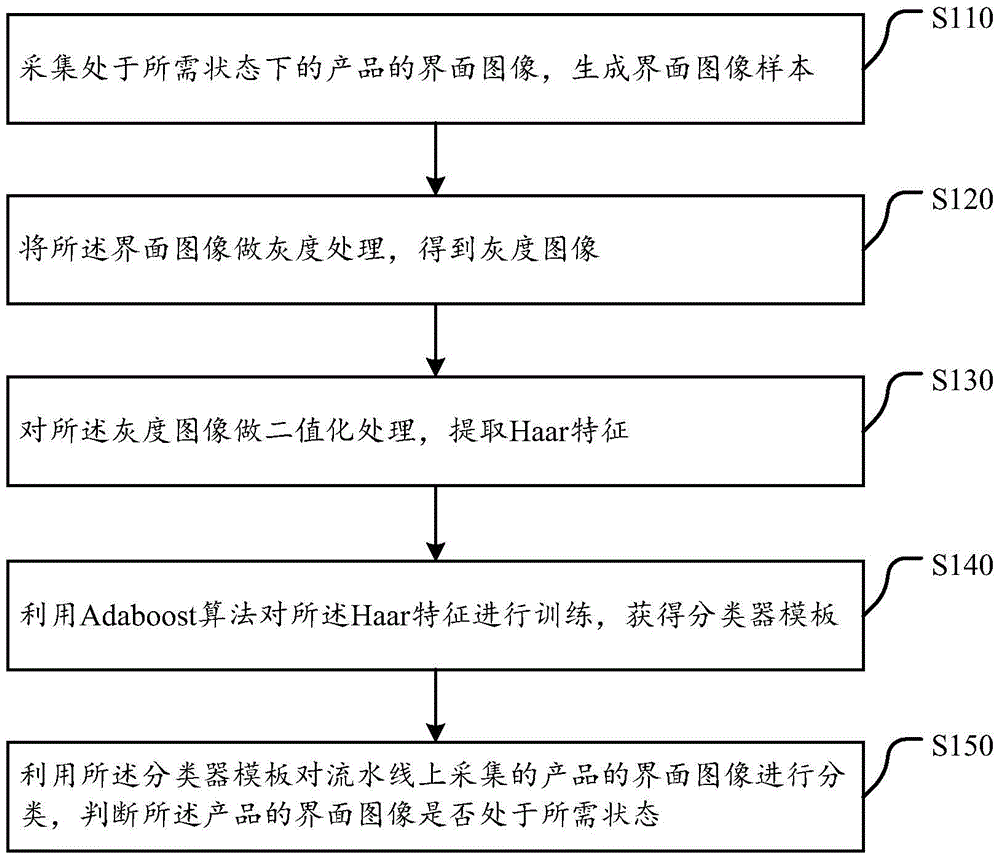

[0080] figure 1 It shows a flow chart of a method for product state detection based on the Adaboost algorithm according to an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0081] Step S110: Collect an interface image of the product in a desired state, and generate an interface image sample.

[0082] Step S120: Perform grayscale processing on the interface image sample to obtain a grayscale image.

[0083] Step S130: Binarize the gray image to extract Haar features.

[0084] Step S140: Use the Adaboost algorithm to train Haar features to obtain a classifier template.

[0085] Step S150: Use the classifier template to classify the interface images of the products collected on the assembly line, and determine w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com