Touch panel assemblage structure

A technology of touch panel and assembling structure, which is applied in the direction of instrument, electrical digital data processing, input/output process of data processing, etc., can solve the problems of broken touch panel 16, difficult disassembly process, foreign matter contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

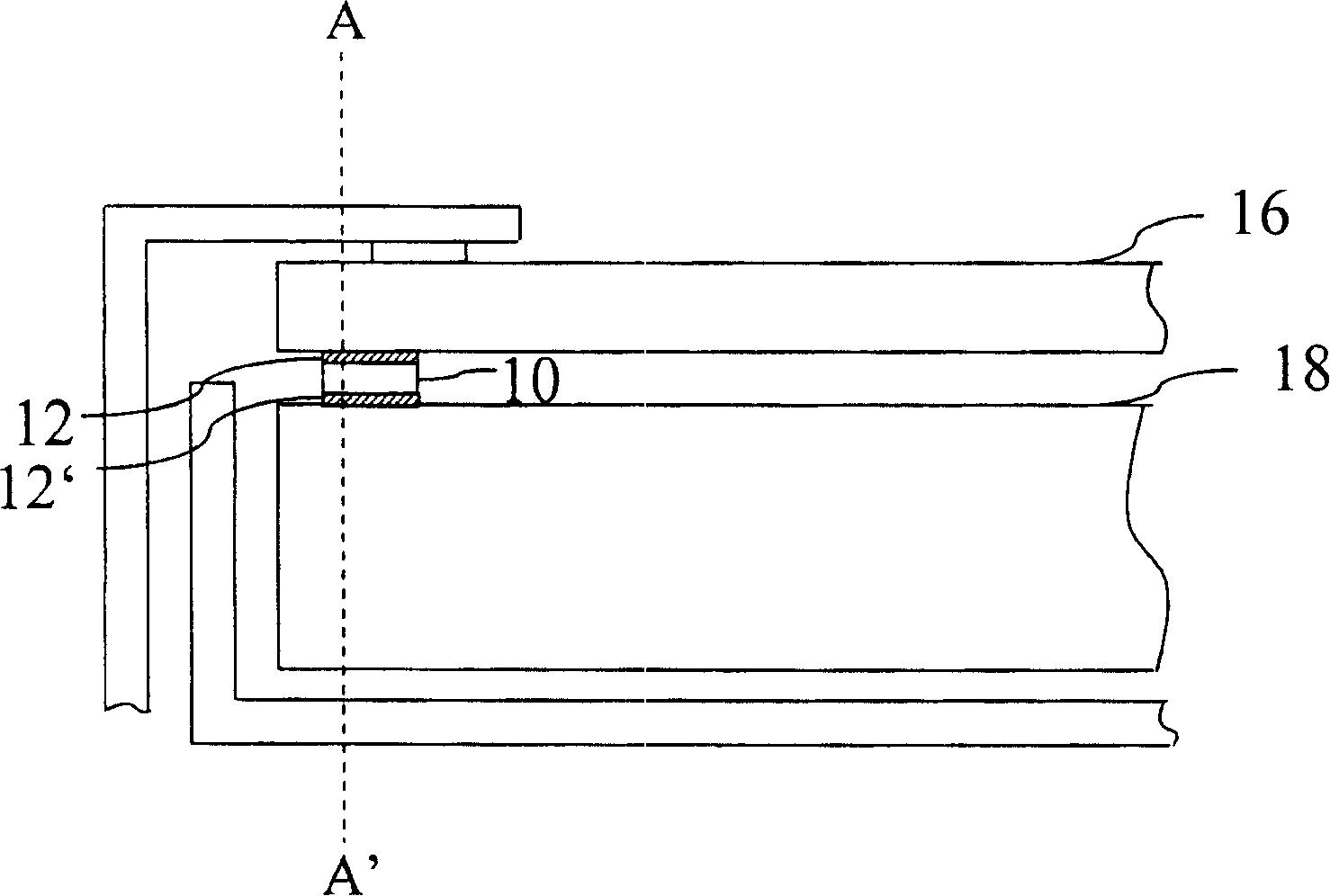

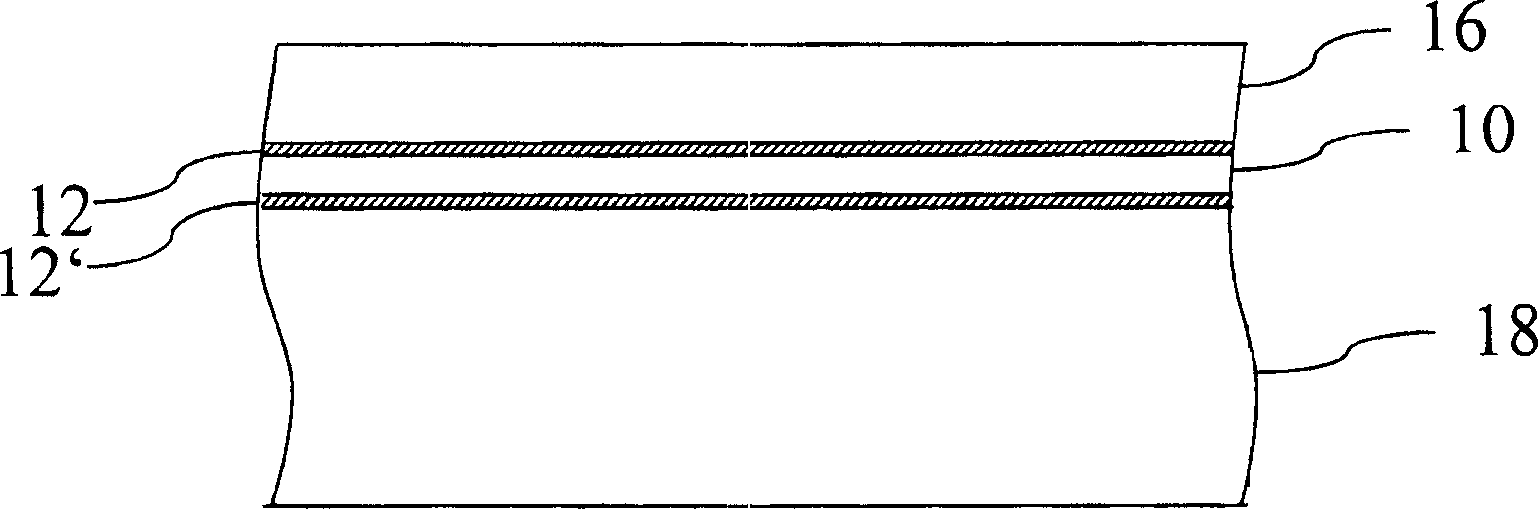

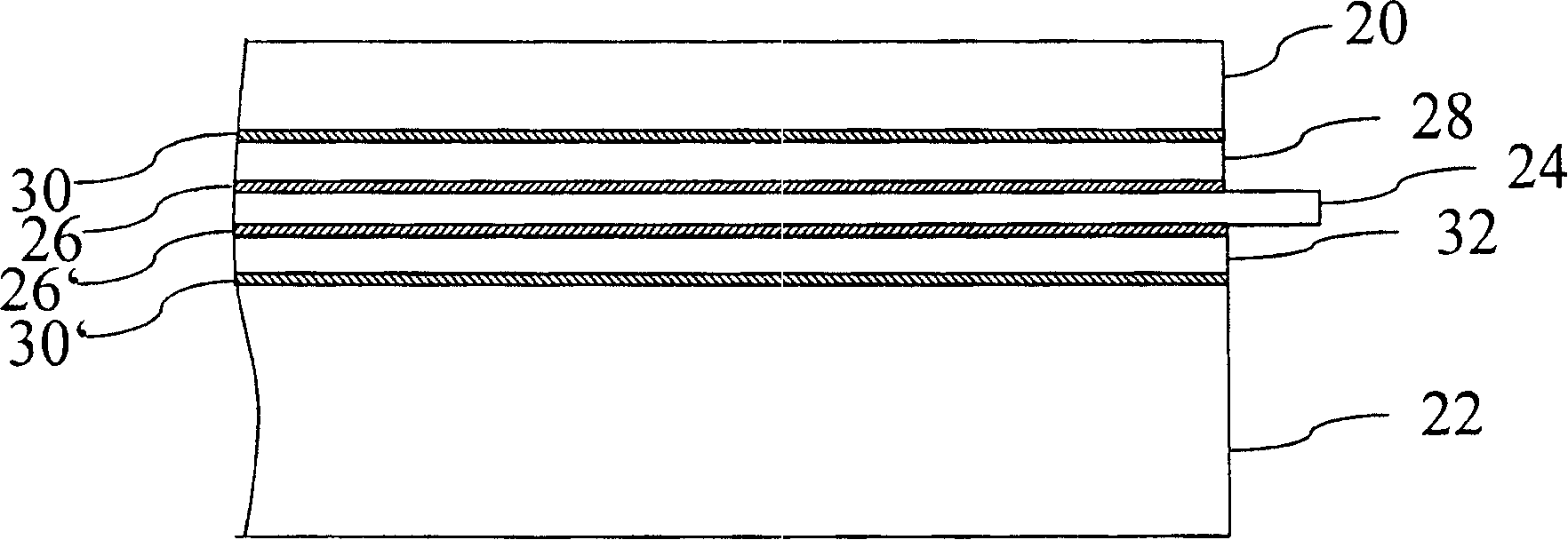

[0037] Please refer to image 3 , which is a touch panel assembly structure according to the first embodiment of the present invention, and is used to fix a touch panel 20 on a display panel 22 of a display. The touch panel assembly structure includes a strip film 24, a first buffer material layer 28 and a second cushioning material layer 32 .

[0038] The strip film 24 is arranged between the touch panel 20 and the display panel 22. The touch panel can be a sonic touch panel, a resistive touch panel or a capacitive touch panel. The material of the strip film 24 can be Mylar or PET polyester film, the tensile strength of polyester film can reach 180 million Pa (Mpa), the elongation at break is 120%, and the thermal shrinkage rate is only 1.2%. And the length of the strip film 24 needs to be such that it can protrude 15-20 mm outside the touch panel 20 , and the protruding part can be attached to the display panel 22 downward at ordinary times. In this embodiment, a strip fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com