Low-floor tramcar power car bogie

A technology for trams and bogies, which is applied in the installation of bogies, railway car body parts, and axle boxes, and can solve problems such as high casting and welding requirements, complex structure of bogie drive systems, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings of the description.

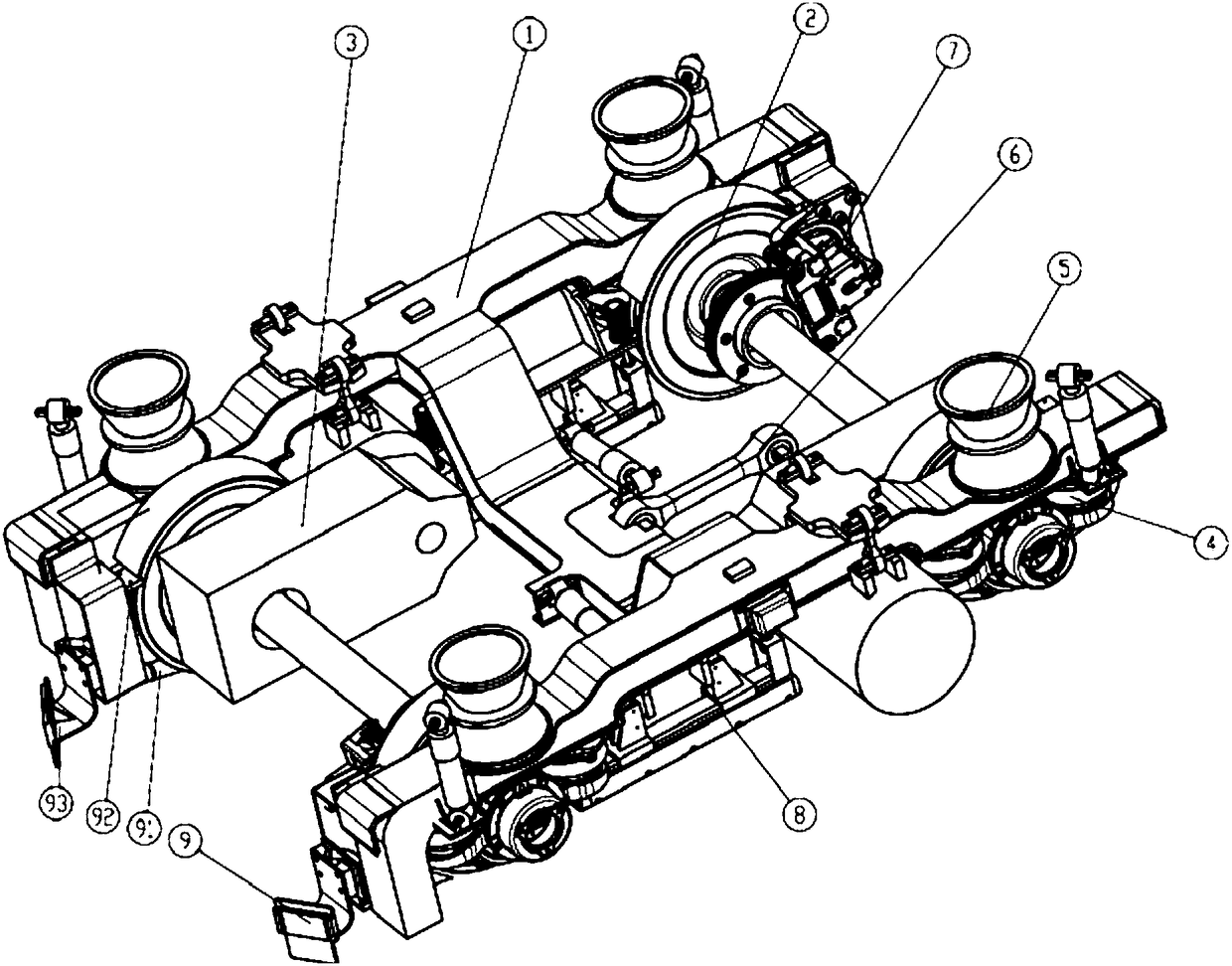

[0042] figure 1 It is a structural diagram of a low-floor tram power car bogie, as attached figure 1 As shown, a low-floor tram power car bogie includes a frame 1, a wheel set 2, a drive system 3, a primary suspension 4, a secondary suspension 5, a traction device 6 connected to the car body, a foundation brake 7, Magnetic rail brake 8, rim lubrication 92, stone sweeper 93 and sand spreading device 91.

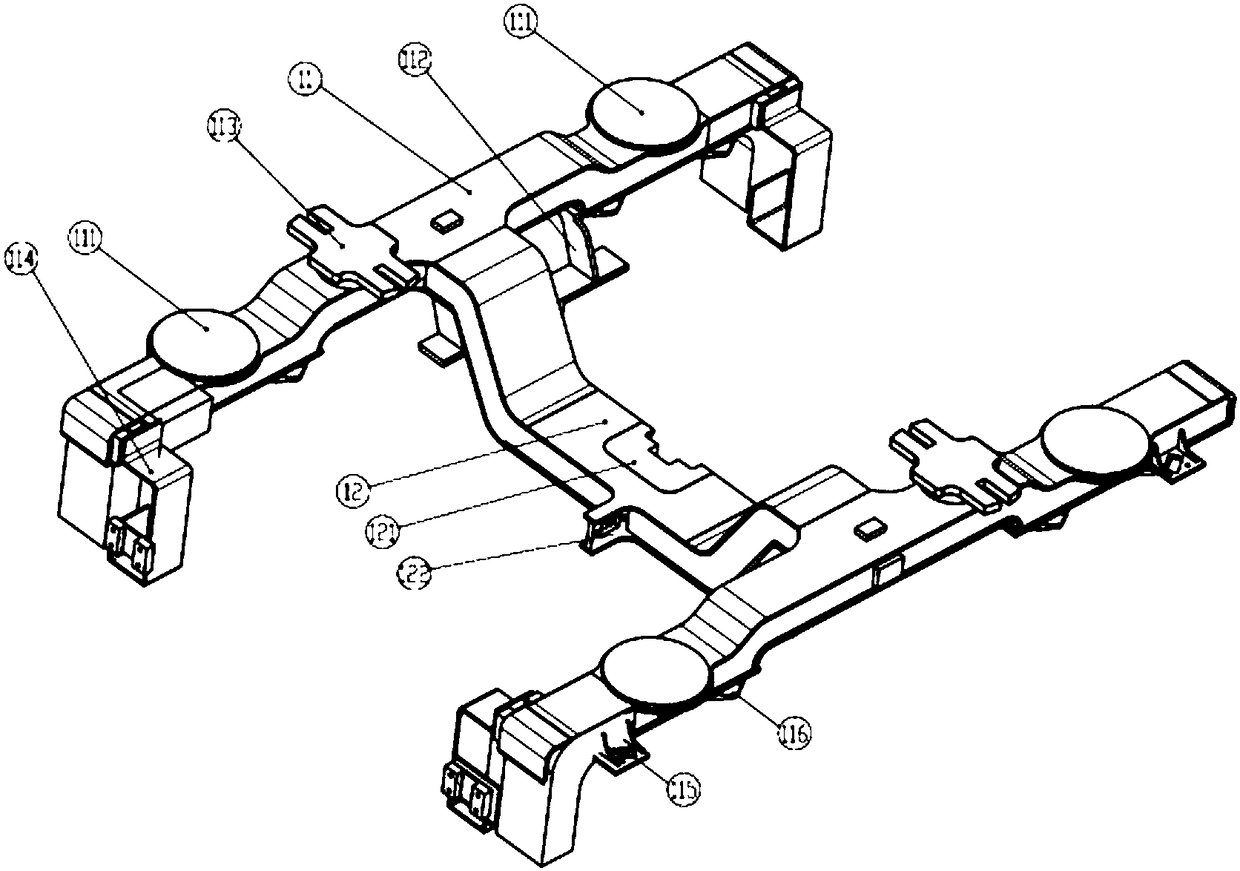

[0043] figure 2 It is a frame structure diagram of a low-floor tram power car bogie, as attached figure 2As shown, the frame 1 is in the shape of an "H" and includes two symmetrically arranged side beams 11 and a cross beam 12 between the two side beams 11 . The side beam 11 is convex, including an n-shaped frame in the middle and end frames connected to both ends of the n-shaped frame. The connection between the end frame and the n-shaped fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com