Downhole gas-liquid transduction booster pump

A booster pump and gas-liquid technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of high energy consumption and high cost of crude oil lifting process, and achieve the effect of efficient development and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

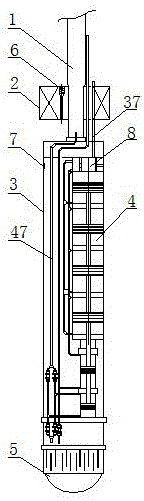

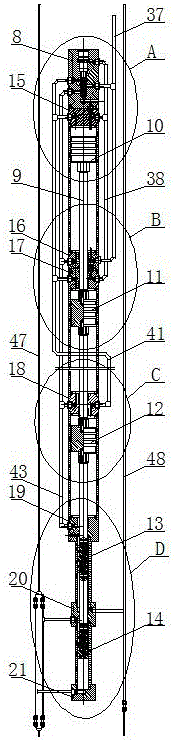

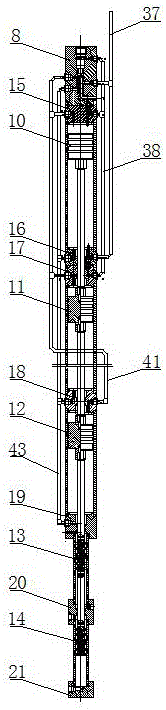

[0024] The downhole gas-liquid transducing booster pump includes a tubing 1, a packer 2, a housing 3, a piston assembly 4 and a filter 5. The tubing 1 is installed on the top of the casing 3, and the tubing 1 is provided with a packer 2. The spacer 2 is provided with a constant pressure valve 6; the upper end of the shell is provided with an air inlet 7. A filter 5 is installed at the bottom of the housing 3 , and a reversing valve 8 is arranged eccentrically in the housing 3 , and a piston assembly 4 is installed below the reversing valve 8 .

[0025] Piston assembly 4 consists of piston rod 9, power piston A10, power piston B11, power piston C12, drainage piston 13, lifting piston 14, end cover A15, end cover B16, end cover C17, end cover D18, end cover E19, end cover The cover F20 and the end cover G21 constitute. Power piston A10, power piston B11, power piston C12, drainage piston 13, lifting piston 14, comprise piston cylinder and piston valve respectively. A power pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com