Automatic assembly device for gear shifter O-shaped ring

An automatic assembly device, O-ring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of slow assembly speed, O-ring assembly that cannot be used for automobile shifters, and inaccurate assembly positions. , to achieve high assembly efficiency, solve the inefficiency of manual operation, and take up less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

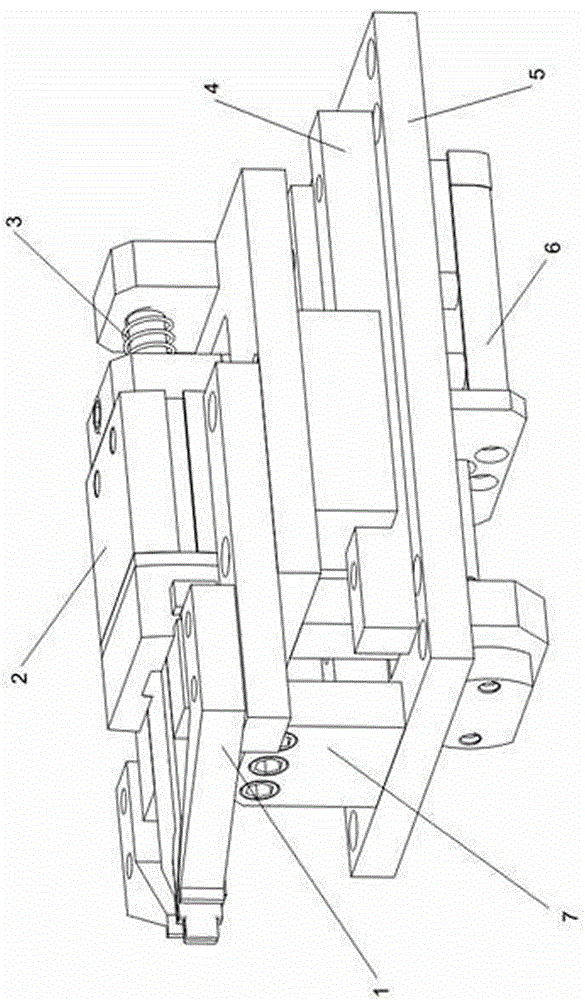

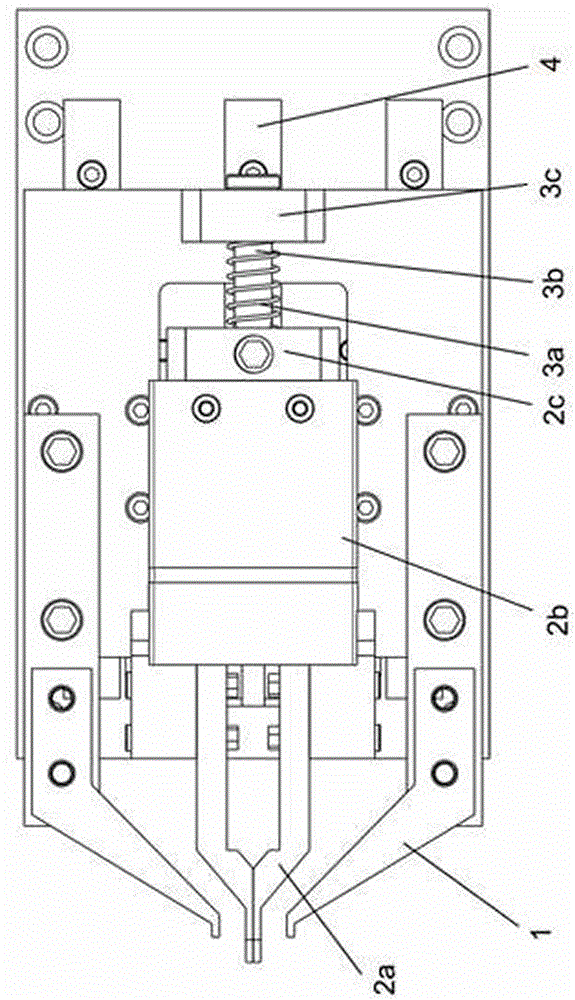

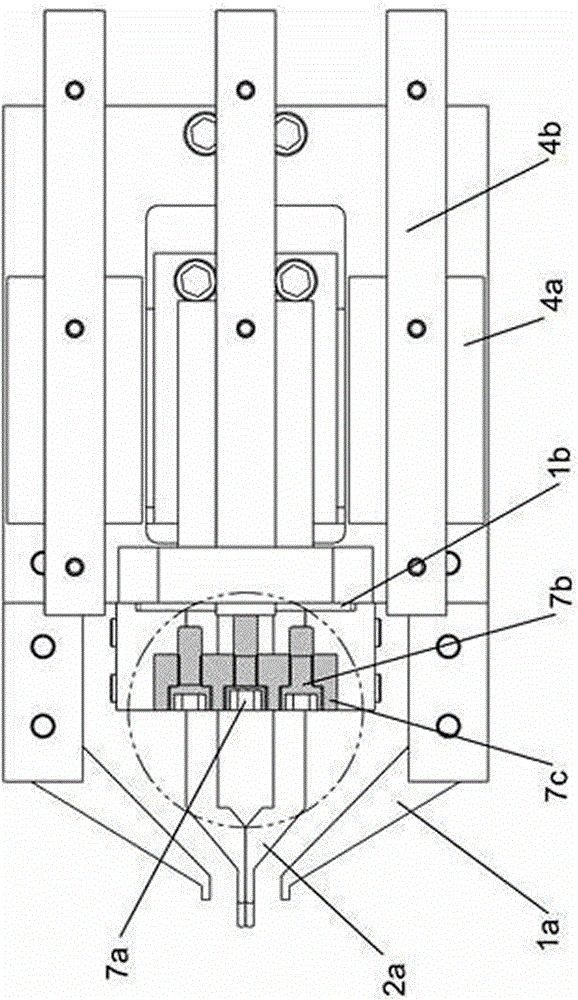

[0023] As shown in the figure, the present invention includes a supporting base, and its structural points are that a cylinder is horizontally arranged at the rear of the lower end of the supporting base; There are sliders on both sides, the upper ends of the sliders on both sides are fixed with the lower ends of both sides of the push claw fixing plate, push claws are set on both sides of the front end of the push claw fixing plate, and air claws are set at the middle opening of the push claw fixing plate, and the lower end of the air claw passes through the middle The slider is set on the middle guide rail, the driving end of the front end of the air claw is connected with the jaw, the rear end of the air claw is connected with the rear end of the push claw fixing plate through a horizontal elastic thrust mechanism; the front end of the support base is provided with a vertical limit plate, which limits The two sides of the positioning plate correspond to the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com