Multichannel rotational flow flame stabilization stepless regulation multifuel combustion combustor

A technology of stepless regulation and burners, which is applied in the direction of burners, lighting and heating equipment, etc., and can solve the problems of high NOx and low thermal efficiency of burners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

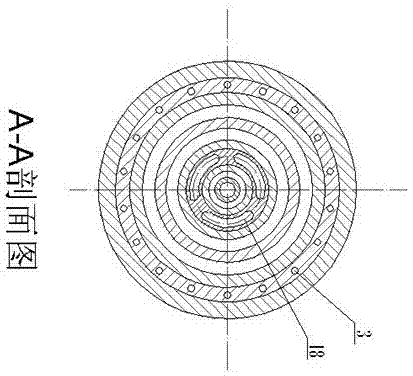

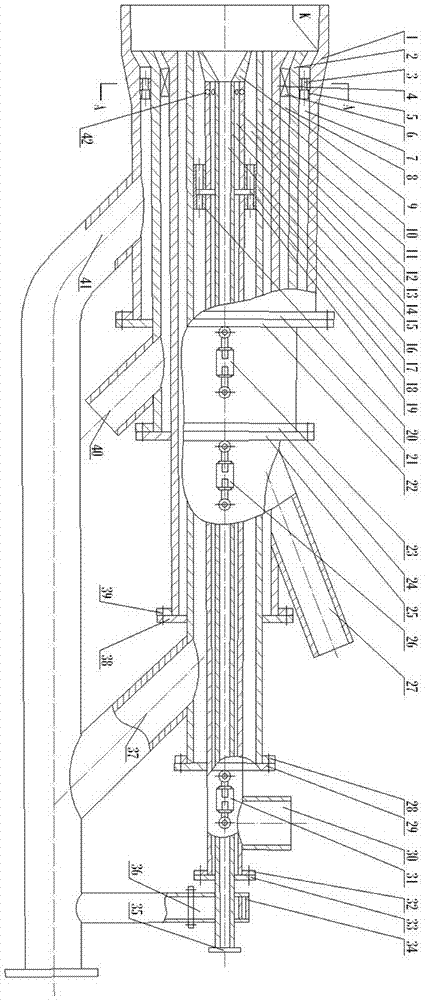

[0006] Specific implementation methods: see figure 1 , figure 2 , this embodiment consists of a burner housing (1), a clean air inner pipe (2), an air distributor (5), a tapered nozzle hole (3), a secondary air inner pipe (4), a swirler (6 ), primary air inner pipe (11), gas pipe (12), gas mixer (17), cone ring flame stabilizer (9), central air pipe (15), and volute cyclone (34). At the center of the casing (1), there is a cone ring flame stabilizer (9), the small head of the flame stabilizer is connected to the central air pipe (15) and the gas pipe (12), and the other end of the central air pipe (15) is connected to There is a volute cyclone (34), an observation hole (35), and a flange (33) is connected to the outer wall of the pipe. The gas pipe (12), the outer wall of the front end pipe is formed with a gas hole (43), the middle part of the front end is connected with a gas mixer (17), and the mixer is formed with a waist circle mixing hole (18), an air hole (20), and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com