Device and method for expanding types of coal suitable for small and medium-sized industrial pulverized coal boilers

A pulverized coal boiler, small and medium-sized technology, applied in the field of equipment for expanding the applicable coal types of small and medium-sized industrial pulverized coal boilers, can solve the problems of high NOx content in flue gas, poor adaptability of coal types, etc., and achieve the suppression of NOx formation and stability Effect of pulverized coal flame, improvement of ignition and combustion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

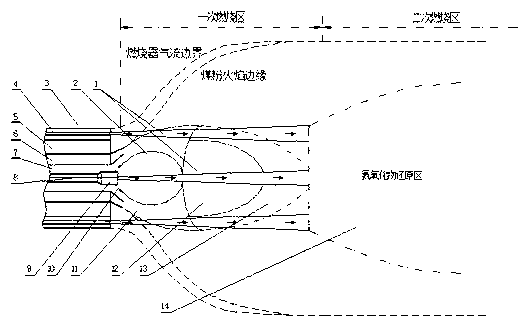

[0023] Such as figure 1 As shown, a device for expanding the types of coal applicable to small and medium-sized industrial pulverized coal boilers includes a swirl burner 3, and at the nozzle of the swirl burner 3, a central delivery pipe 8, a central air passage 7, The primary air powder channel 6, the secondary air pipe, the secondary air pipe includes the inner secondary air channel 5 and the outer secondary air channel 4 and the inner secondary air channel 5 is located inside the outer secondary air channel 4, and the central conveying pipe 8 The central air output, the primary air output from the primary air powder channel 6, and the external secondary air output from the external secondary air duct are all direct-flow, and the primary air is not only used for combustion, but also transports coal powder to the swirl combustion The role of the primary air nozzle of the device 3, the pulverized coal delivery ratio of the primary air is 0.8~1.2kg / kg, the internal secondary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com