Biomass gas steam generator

A steam generator and biomass gas technology, applied in steam generation, steam boilers, gas fuel burners, etc., can solve the problems of high energy consumption of fans, increase of furnace cross-sectional area, unfavorable application of miniaturization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention rather than limit the scope of the present invention, and those skilled in the art can make some non-essential improvements and adjustments based on the content of the above invention.

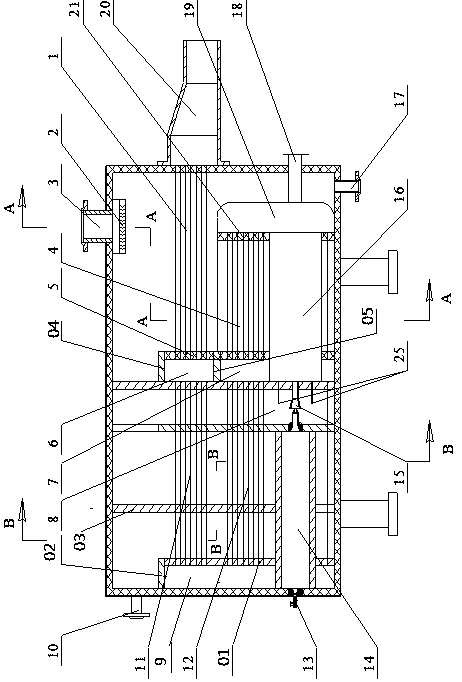

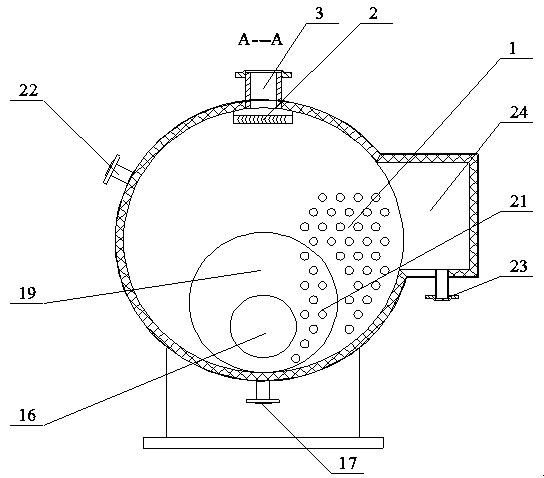

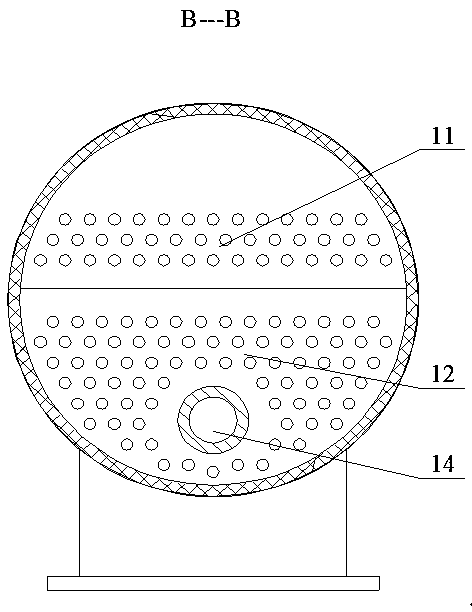

[0041] Such as figure 1 , Figure 3-5 Shown, a kind of biomass gas steam generator, the described biomass gas steam generator is provided with divider, and described divider divides biomass gas steam generator into secondary air preheating chamber and liquid chamber; The secondary air preheating chamber is equipped with vertical partitions A01, 01 horizontal partitions A03, baffles I02, baffles II and pre-combustion chamber 14; the vertical partitions A01, horizontal partitions A03 and steam generator shell The body forms the front smoke return chamber 9, and the pre-combustion chamber 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com