Spiral-flow type fishtail high-efficiency energy-saving burner

A high-efficiency, energy-saving, swirling technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problems of polluting the kitchen environment, low furnace temperature, and inability to burn normally, and reduce NOX emissions and furnace radiation. High temperature, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

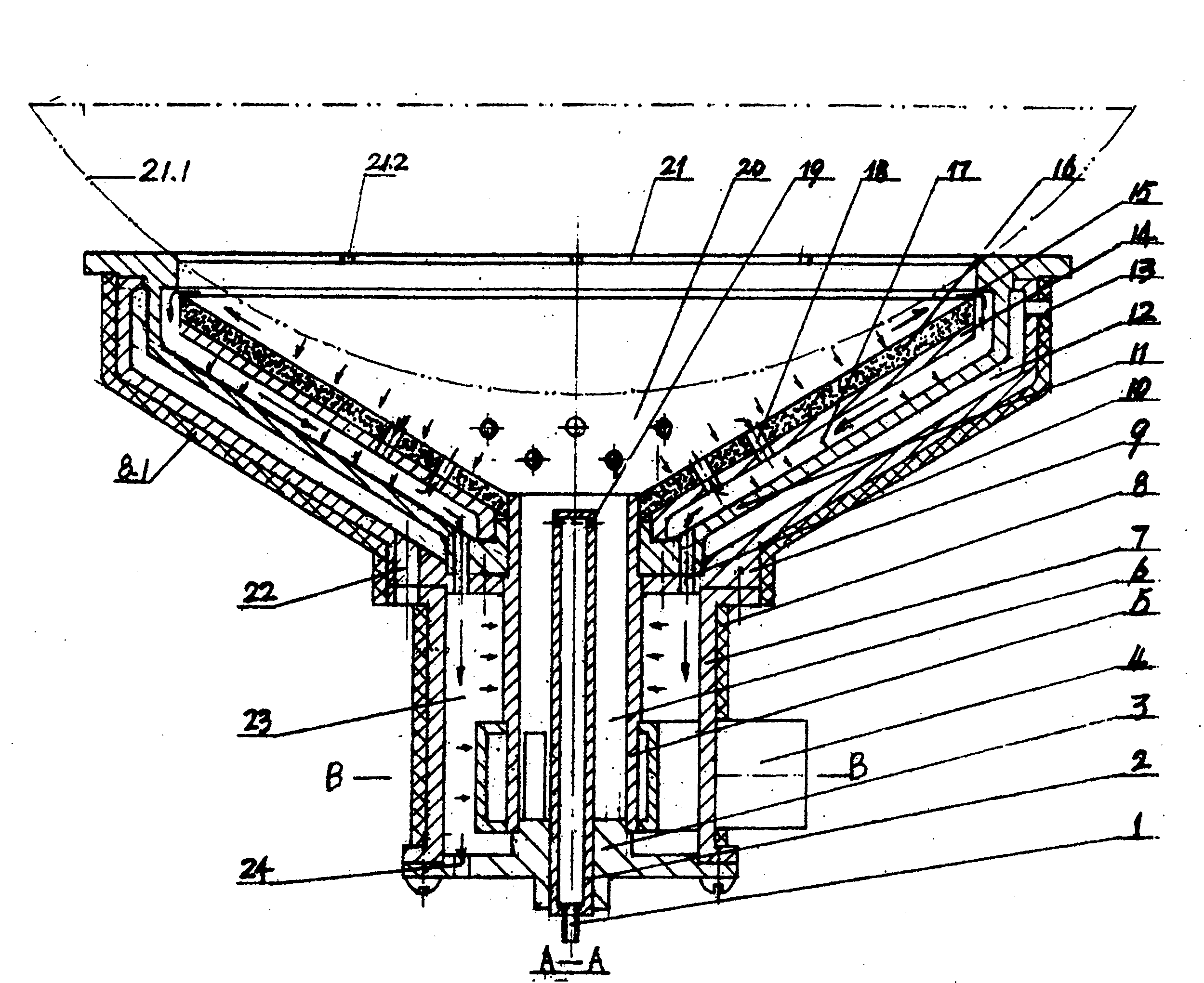

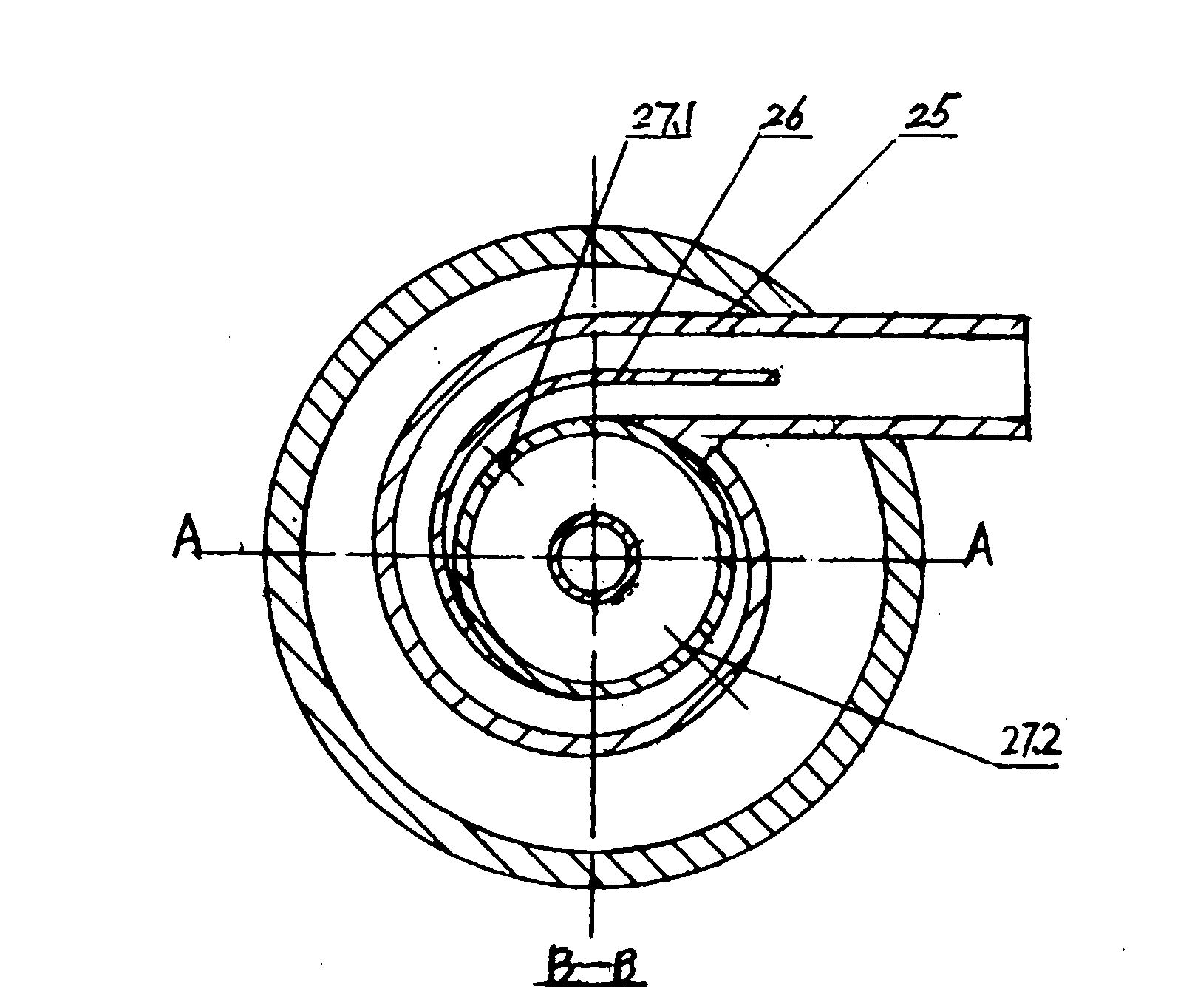

[0019] Examples; see figure 1 , figure 2. The high-efficiency and energy-saving swirling fan flame burner includes an expansion cover (11), the upper inner ring of the expansion cover (11) is used to place the hob (21) of the frying pan (21.1), and the expansion cover ( 11) The inner layer is a hollow interlayer structure with a smoke chamber (17), and the inner circle of the lower part of the expansion cover (11) is connected with a cylindrical channel (5). The outer wall of the lower part of the cylindrical channel (5) is provided with ventilation mouth (27.1, 27.2), the lower step of the cylindrical passage (5) is equipped with a swirl air distributor (25), and the swirl air distributor (25) is provided with an air inlet connected to the blower (4). A return pipe (2) is provided at the center of the shaped channel (5), and a number of gas through holes (19) are formed on the outer wall circumference of the upper end of the return pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com