Polyimide resin synthesis method

A technology of polyimide resin and synthesis method, which is applied in the field of polyimide resin synthesis, can solve problems such as unsatisfactory heat conduction and failure to meet the needs of electronic components, and achieve excellent electrical properties and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

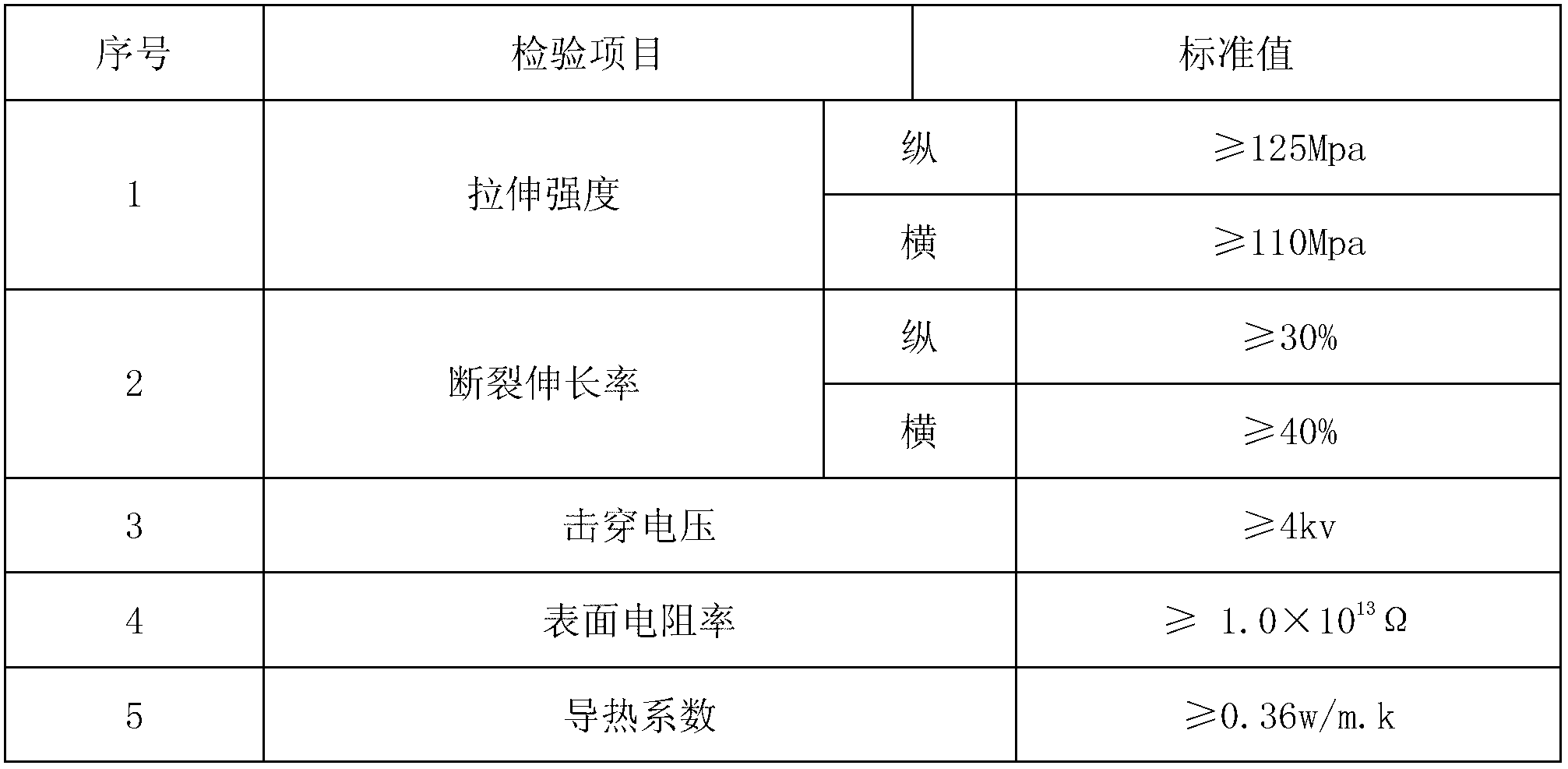

[0012] A kind of synthesis method of polyimide resin described in this embodiment, described resin solid is by pyromellitic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) synthesis reaction The polyamic acid (PAA) that obtains, described heat-conducting nano-powder mixture is Al 2 o 3 (Al2O3), NB (Nitride Boride) and AlN (Aluminum Nitride) are a mixture of three thermally conductive nano-powders, the ratio is calculated in parts by weight: Al 2 o 3 30 parts, NB40 parts, AlN30 parts, total amount is 1((the ratio of part is mixed, and heat-conducting nano-powder mixture accounts for 10% of resin solids total amount; During synthesis, at first pyromellitic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) calculates the required reaction amount according to the equimolar ratio (wherein: PMDA: molecular weight 218.12; ODA molecular weight: 200.24), and synthesizes polyamic acid (PAA), and its synthesis process In the process, first place the 4,4'-diaminodiphenyl ...

Embodiment 2

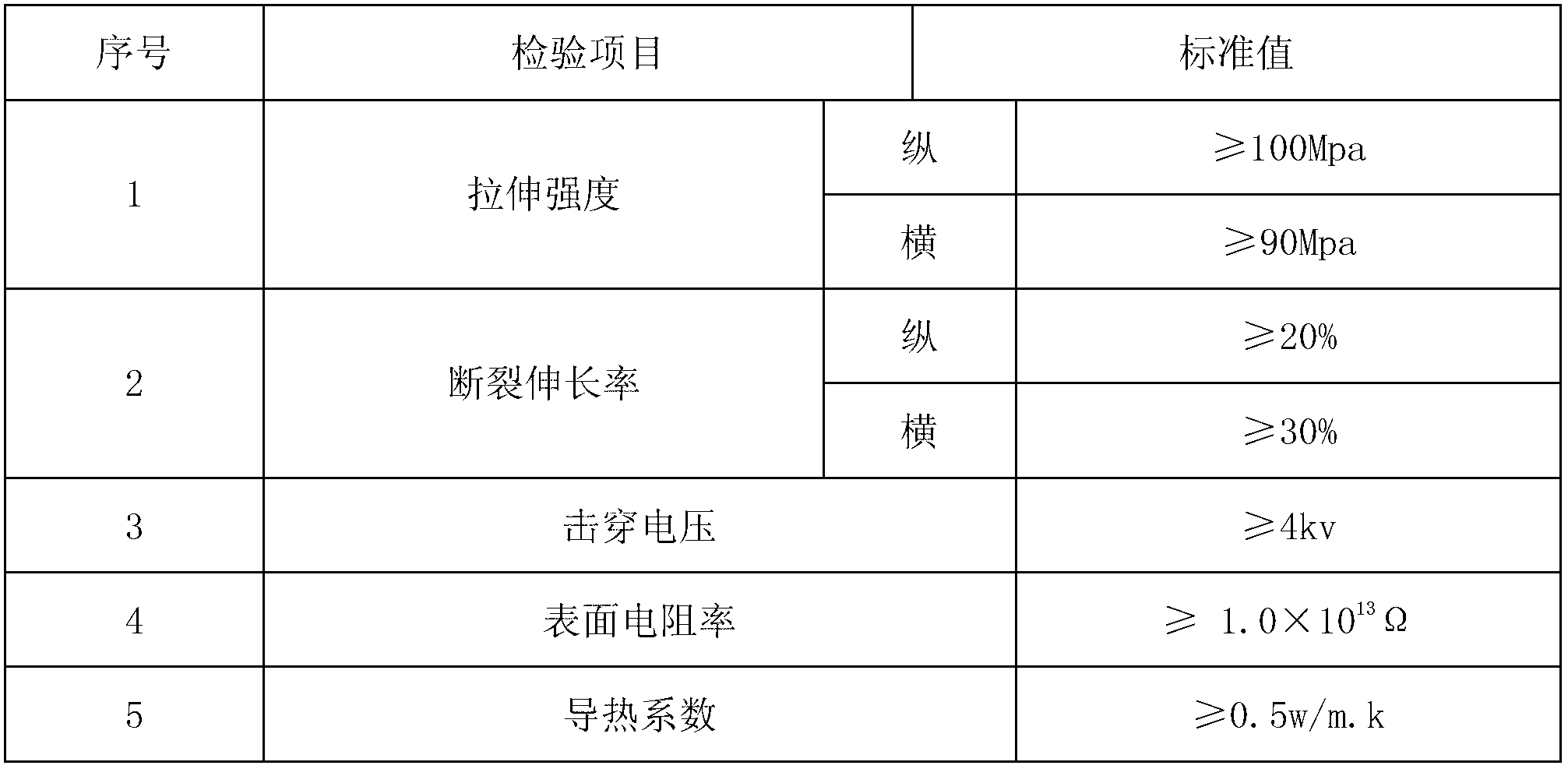

[0017] In the synthesis method of a polyimide resin provided in this embodiment, the heat-conducting nano-powder mixture is Al2O340%, NB50%, AlN60%, and the heat-conducting nano-powder mixture accounts for 30% of the total resin solids. During the synthesis of polyamic acid (PAA), the amount of pyromellitic dianhydride (PMDA) added is 95% of the total calculated amount. After testing, the performance indicators shown in the following table 2 can be achieved:

[0018] Table 2:

[0019]

Embodiment 3

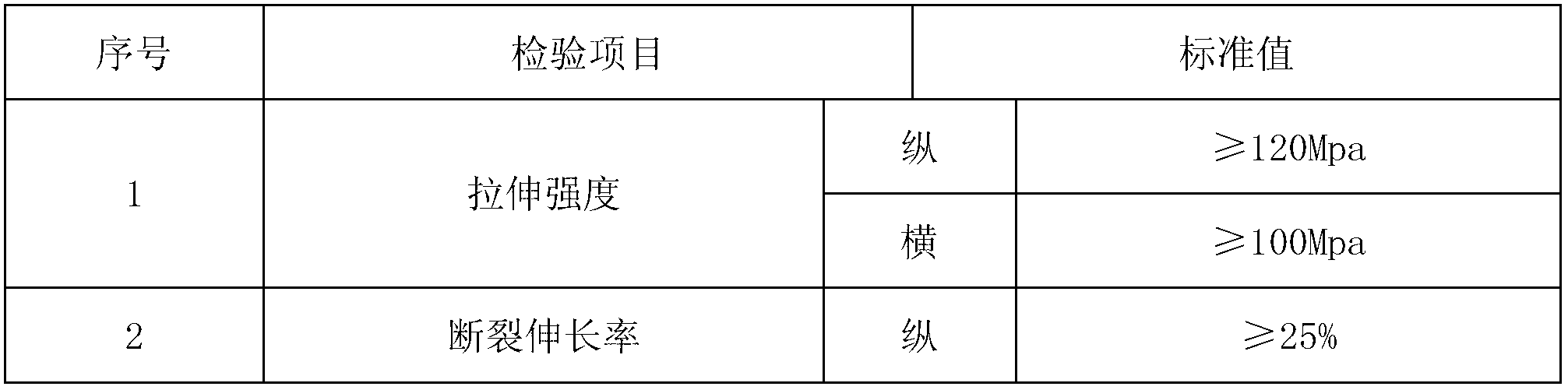

[0021] A kind of synthetic method of polyimide resin that present embodiment provides, described heat-conducting nano-powder mixture is Al 2 o 3 10%, NB20%, AlN20%, heat-conducting nano-powder mixture accounts for 20% of the total resin solids, and during the synthesis of polyamic acid (PAA), the amount of pyromellitic dianhydride (PMDA) added reaches 93%. After testing, the performance indicators shown in Table 3 below can be achieved.

[0022] table 3:

[0023]

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com