Corona-resistant PI (polyimide) film and preparation method thereof

A corona-resistant and thin-film technology, which is applied in the field of corona-resistant PI thin films and their preparation, can solve problems such as imperfect flatness and intrinsic properties, difficult control of the preparation process, and poor dimensional stability, so as to improve flatness and Intrinsic performance, improvement of corona resistance performance, effect of potential processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

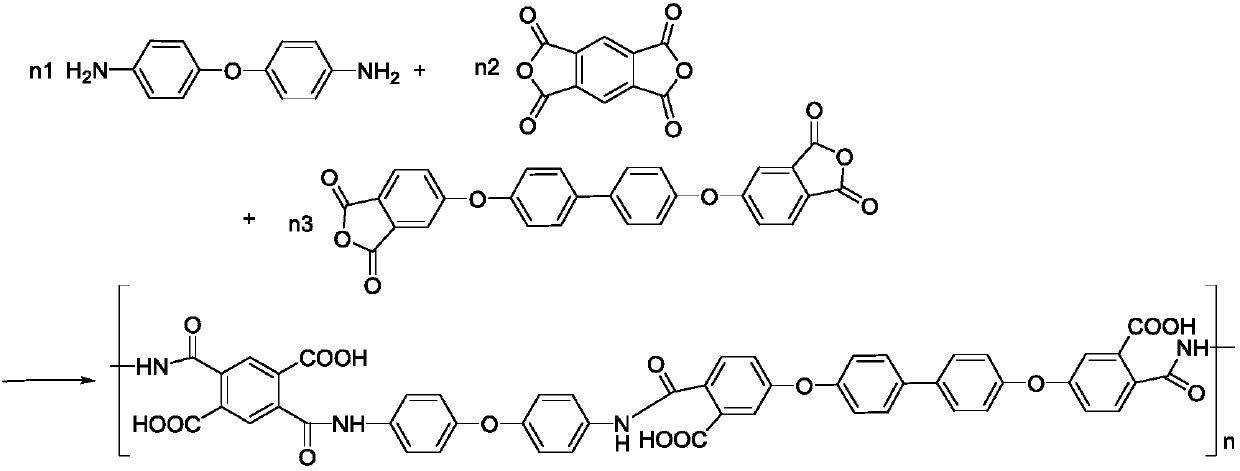

Method used

Image

Examples

Embodiment 1

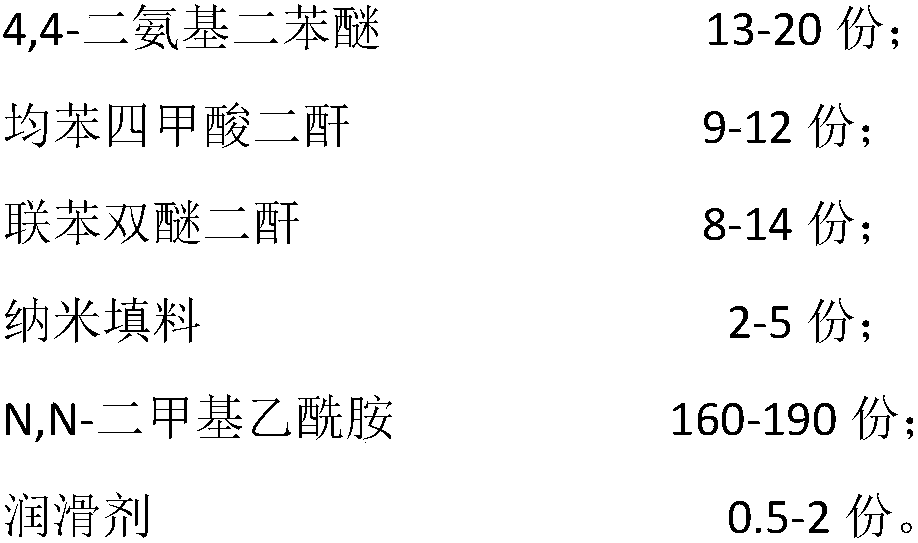

[0023] A kind of anti-corona PI film is made up of following components by weight parts:

[0024]

[0025]

[0026] The preparation method of corona resistant PI thin film, comprises the following steps:

[0027] a. Grinding and fully grinding 4,4-diaminodiphenyl ether, pyromellitic dianhydride and biphenyl bisether dianhydride respectively;

[0028] b. Add the raw materials 4,4-diaminodiphenyl ether, pyromellitic dianhydride, and biphenyl ether dianhydride obtained in step a into the reactor with N,N-dimethylacetamide added respectively , after mixing and reacting, add nano-fillers and lubricants, mix evenly, and perform defoaming treatment on the synthesized polyamic acid solution;

[0029] c. Press the polyamic acid solution defoamed in step b into the casting nozzle storage tank on the front head through the pipeline from the stainless steel solution storage tank, and the steel strip in the casting machine runs at a constant speed, and the polyamic acid solution in ...

Embodiment 2

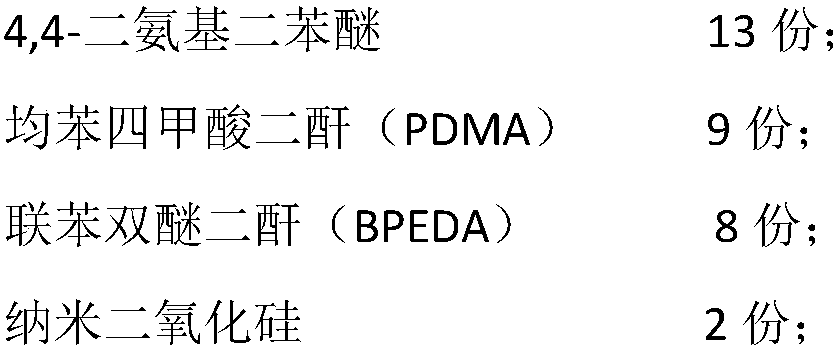

[0033] A kind of anti-corona PI film is made up of following components by weight parts:

[0034]

[0035] The preparation method is as in Example 1.

Embodiment 3

[0037] A kind of anti-corona PI film is made up of following components by weight parts:

[0038]

[0039]

[0040] The preparation method is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com