Biaxially oriented polyimide film for flexible printed circuit board base material and preparation method of biaxially oriented polyimide film

A polyimide film and flexible printed circuit technology, which is applied in the field of organic polymer material preparation, can solve the problems of uneven film thickness, thermal expansion damage, inability to bond together flexible copper clad, etc., to achieve good The effect of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

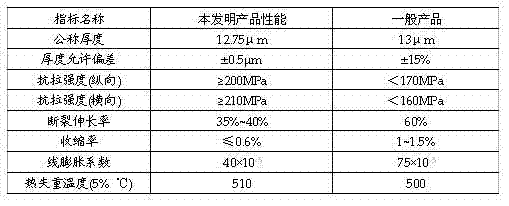

Image

Examples

Embodiment 1

[0029] The ratio of raw materials in this example is: p-phenylenediamine (PDA) 2.78%g, biphenyltetracarboxylic dianhydride (BPDA) 6%, diaminodiphenyl ether (ODA) 8%, pyromellitic dianhydride ( PMDA)12.8%, Dimethylacetamide (DMAC)70.42%Kg

[0030] The above-mentioned raw materials are accurately weighed according to the predetermined proportion and then used for later use.

[0031] Put the weighed dimethylacetamide into the reaction kettle, add all p-phenylenediamine, mix for 15 minutes, add the weighed biphenyltetracarboxylic dianhydride, stir for 30 minutes, add all the diamino di Phenyl ether, and then add pyromellitic dianhydride in three to four times while stirring. Stir for 3 hours, then perform defoaming treatment, vacuumize the inside of the tank to allow the reacted stock solution to stand under negative pressure for 10 hours, so that the bubbles in the stock solution float up and come out.

[0032] After the raw liquid is filtered, it is pumped into the die head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com