Biochar-based soil modifier and application thereof

A soil conditioner, biochar technology, applied in the application, biofuel, soil conditioning materials and other directions, can solve the problems of treating the symptoms but not the root cause, and not fundamentally improving the physical and chemical properties of white mud soil, so as to prolong the fertilizer efficiency and increase the living environment. and quantity, the effect of improving fertilizer utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

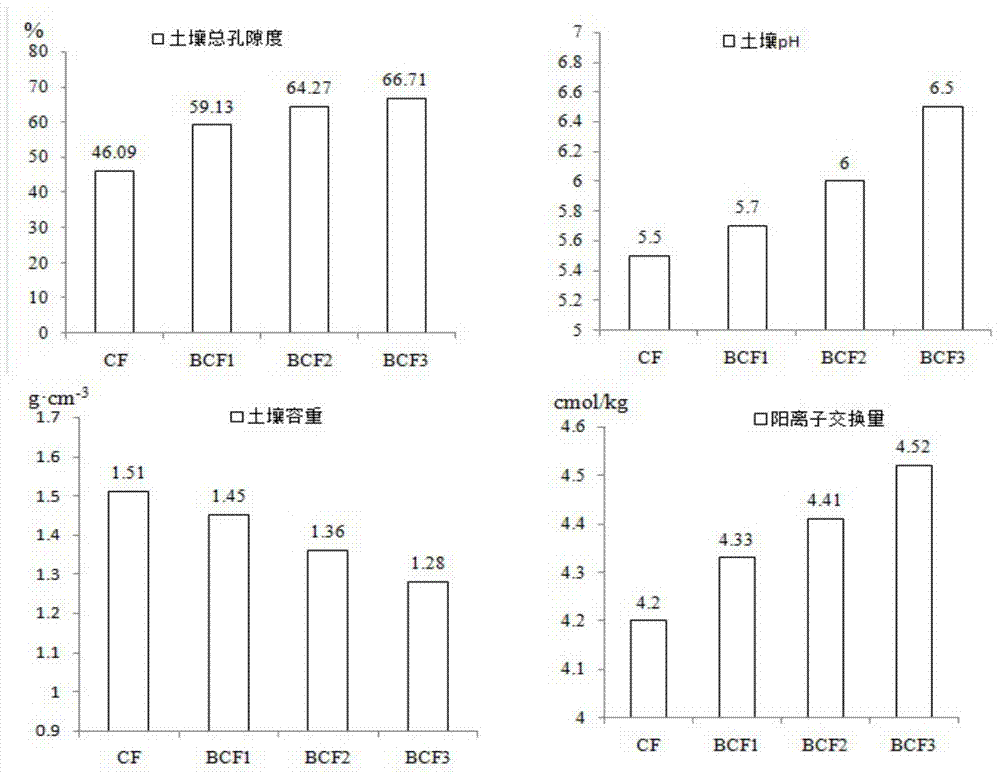

[0032] Experiments on the effect of adding biochar to soil bulk density and porosity by planting rice in white pulp soil in the eastern part of Heilongjiang Province. The following treatments were set in the experiment:

[0033] Preparation of biomass straw charcoal: After drying and pulverizing rice straw, conduct high-temperature pyrolysis carbonization treatment in a furnace at 500°C for 3 hours, after carbonization, cool and pulverize, pass through a 2mm sieve to obtain biochar raw material.

[0034] (1) No addition of biochar (CF, Conventional fertilizer), blank control;

[0035] (2) Biochar treatment 1 (BCF1, Biological conventional fertilizer): single application of biochar, the application rate is 7.5 tons / ha;

[0036] (3) Biochar treatment 2 (BCF2, Biological conventional fertilizer): single application of biochar, the application rate is 10 tons / ha;

[0037] (4) Biochar treatment 3 (BCF3, Biological conventional fertilizer): single application of biochar, the applic...

Embodiment 2

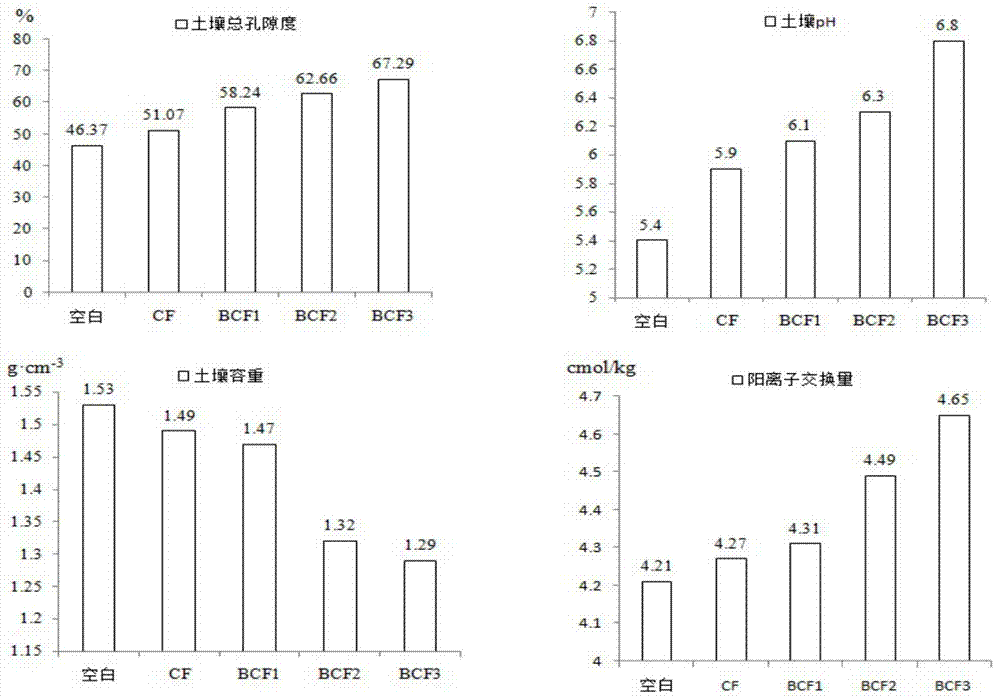

[0042] Comparison of leaching experiments on the nutrient loss of white pulp soil by adding biomass charcoal and chicken manure to plant rice in white pulp soil in eastern Heilongjiang Province:

[0043] Preparation of biomass straw charcoal: After drying and pulverizing the corn stalks, conduct high-temperature pyrolysis carbonization treatment in a furnace at 700°C for 2 hours, after carbonization, cooling and pulverization, pass through a 2mm sieve to obtain biochar raw materials.

[0044] Pretreatment of chicken manure: add raw chicken manure to the special RW fermentation agent for organic fertilizer production (or organic material decomposing agent) at room temperature for aerobic fermentation, the raw chicken manure and the special RW fermentation bacteria for organic fertilizer production The weight ratio of the agent is 50:1. By overturning and stirring, ensure that the special RW fermentation agent for organic fertilizer production can be mixed evenly with the chicken m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com