Wear-resistant intake valve and preparation method thereof

An intake valve and alloy composition technology, applied in mechanical equipment, lift valves, valve devices, etc., can solve the problems of high price, toughness can not meet the standards of industrial applications, etc., to improve surface strength, mechanical and chemical properties improvement , the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

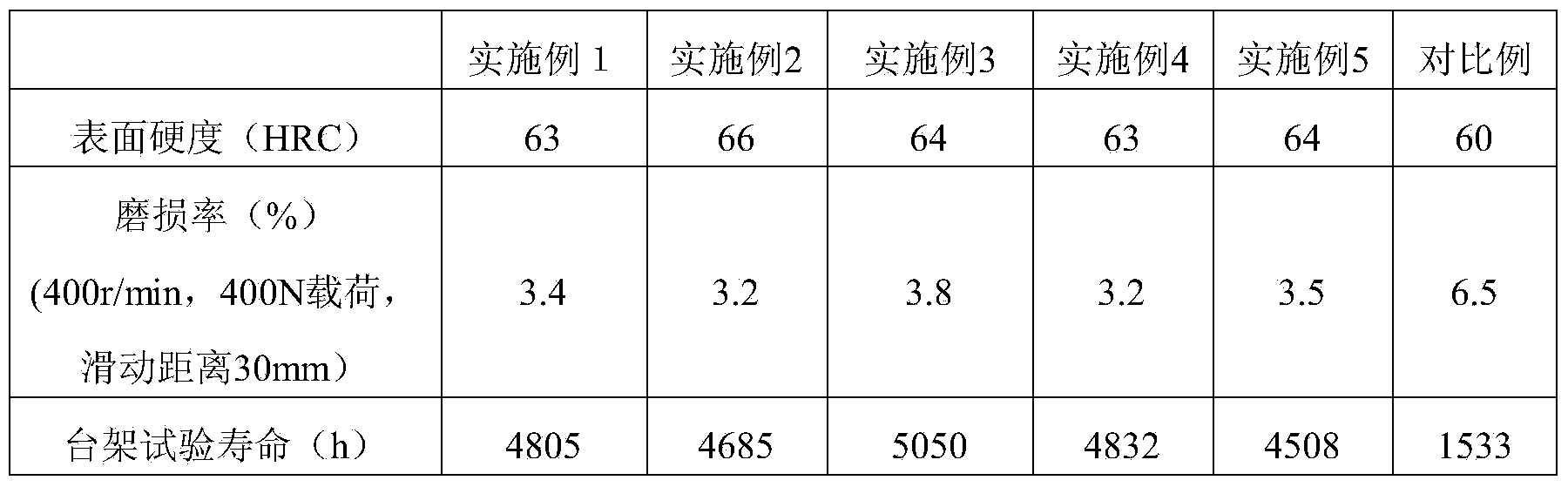

Examples

Embodiment 1

[0023] The wear-resistant intake valve is processed by surface nano-technology, low-temperature nitriding, surfacing welding tungsten-zirconium alloy and other processes. The specific steps are as follows:

[0024] (1) Ingredients, the weight percentage of the alloy material used is: C: 0.32%; Si: 0.17%; Mo: 1.2%; Mn: 0.50%; Nb: 0.5%; Cr: 0.80%; W: 0.50%; For Fe with a purity of 99.8%, mix the alloy material evenly;

[0025] (2) Melting in a vacuum induction furnace at a temperature of 1600°C for 1.5 hours;

[0026] (3) Adopt forging molding to obtain the valve blank;

[0027] (4) Carry out quenching and tempering heat treatment, that is, heat preservation at 850 ° C for 1 hour, quenching, then heating to 500 ° C, heat preservation for 2 hours, and finally air cooling; then cutting, the processing conditions are: the impact head is spherical, and the output end is circular The radius is 2mm, the rotation speed is 200r / min; the amplitude of the impact head is 5μm; finally, th...

Embodiment 2

[0033] The wear-resistant intake valve is processed by surface nano-technology, low-temperature nitriding, surfacing welding tungsten-zirconium alloy and other processes. The specific steps are as follows:

[0034] (1) Ingredients, the weight percentage of the alloy material used is: C: 0.40%; Si: 0.27%; Mo: 0.5%; Mn: 0.80%; Nb: 0.2%; Cr: 1.10%; W: 1.0%; For Fe with a purity of 99.8%, mix the alloy material evenly.

[0035] (2) Melting in a vacuum induction furnace at a temperature of 1650°C for 1 hour;

[0036] (3) Adopt forging molding to obtain the valve blank;

[0037] (4) Carry out quenching and tempering heat treatment, that is, heat preservation at 850°C for 1.5h, quenching, then heating to 500°C, heat preservation for 2 hours, and finally air cooling; then cutting, the processing conditions are: the impact head is spherical, and the output end is round The radius of the arc is 2mm, the rotational speed is 200r / min; the amplitude of the impact head is 5μm; finally, th...

Embodiment 3

[0043] The wear-resistant intake valve is processed by surface nano-technology, low-temperature nitriding, surfacing welding tungsten-zirconium alloy and other processes. The specific steps are as follows:

[0044] (1) Ingredients, the weight percentage of the alloy material used is: C: 0.34%; Si: 0.25%; Mo: 0.75%; Mn: 0.60%; Nb: 0.3%; Cr: 1.00%; W: 0.80%, the remainder For Fe with a purity of 99.8%, mix the alloy material evenly;

[0045] (2) Melting in a vacuum induction furnace at a temperature of 1630°C for 1.2 hours;

[0046] (3) Adopt forging molding to obtain the valve blank;

[0047] (4) Carry out quenching and tempering heat treatment, that is, heat preservation at 800°C for 1 hour, quenching, then heating to 500°C, heat preservation for 2.5 hours, and finally air cooling; then cutting, the processing conditions are: the impact head is spherical, and the output end is circular The radius is 2mm, the rotation speed is 200r / min; the amplitude of the impact head is 5μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com