Superhydrophobic nanofiber membrane and preparation method thereof

A nanofiber membrane and superhydrophobic technology, which is applied in the preparation of superhydrophobic nanofiber membranes and the field of superhydrophobic nanofiber membranes, can solve the problems of limited practical application and poor mechanical properties of fiber membranes, and achieve the effect of improving oil-water separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

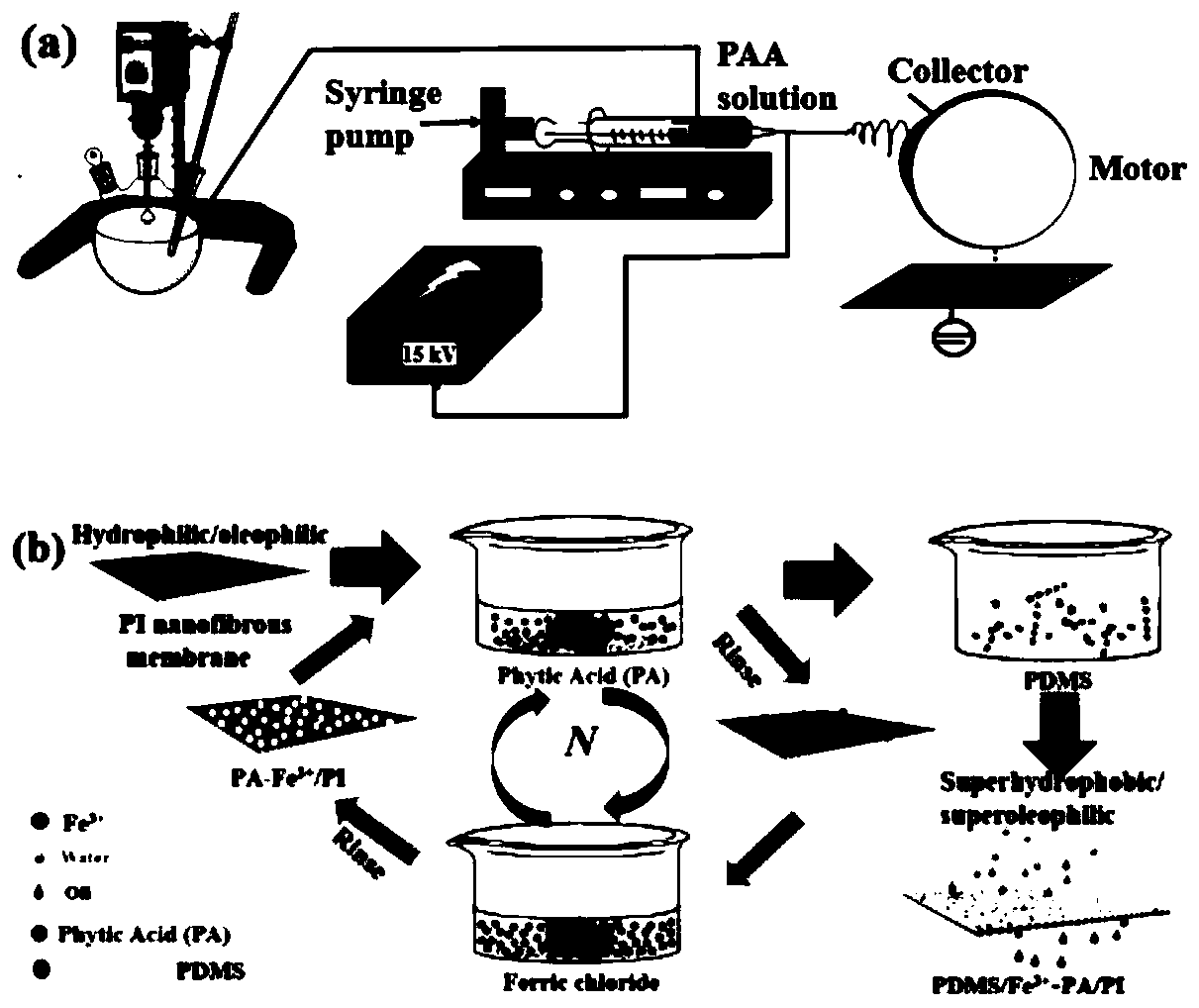

[0032] equipped with mechanical stirrer, thermometer, N 2 Into the 100mL three-necked round-bottomed flask leading out the inlet and outlet tubes, add 0.01mol of BPDA and 0.01mol of PDA, and mix uniformly. With strong mechanical stirring, 40 mL of DMAc solution was added. A low temperature reactor was used to control the reaction temperature at -5 °C. The flask was then connected to a nitrogen cylinder, under N 2 After reacting in the environment for 24 hours, it is found that the rod climbing phenomenon occurs in the flask, and the reaction can be terminated by exposing the reaction to the air to obtain the PAA polymer.

[0033]The preparation of polyamic acid (PAA) nanofiber film is dissolved in DMAc with the PAA polymer of above-mentioned gain, obtains the DMAc solution containing 3wt% PAA, adds the hexadecyl trimethyl bromide of 1‰ (wt%) ammonium to enhance its conductivity, placed under a magnetic stirrer and stirred for 1 h to obtain a uniformly mixed solution. Then ...

Embodiment 2

[0035] (1) The PI film (2cm×2cm) prepared in Example 1 was placed in ethanol and deionized aqueous solution and ultrasonically treated for 30 minutes to remove surface impurities.

[0036] (2) Accurately weigh 2.7029g ferric chloride hexahydrate solid, dissolve it with deionized water, and obtain 0.01mol / L FeCl at constant volume 3 solution.

[0037] (3) Immerse the cleaned PI membrane in FeCl 3 In the solution for 2min, the positively charged Fe 3+ / PI membrane, and then use distilled water to remove excess FeCl on the surface of the membrane 3 .

[0038] (4) The obtained positively charged Fe 3+ / PI membrane immersed in 0.013mol / L phytic acid (PA) solution for 2min to obtain negatively charged PA-Fe 3+ / PI membrane, and rinse the membrane thoroughly with distilled water to remove excess PA solution. In this manner as described above, one cycle of self-assembly is completed, and the process is repeated to obtain the desired number of cycles of self-assembly on the PI na...

Embodiment 3

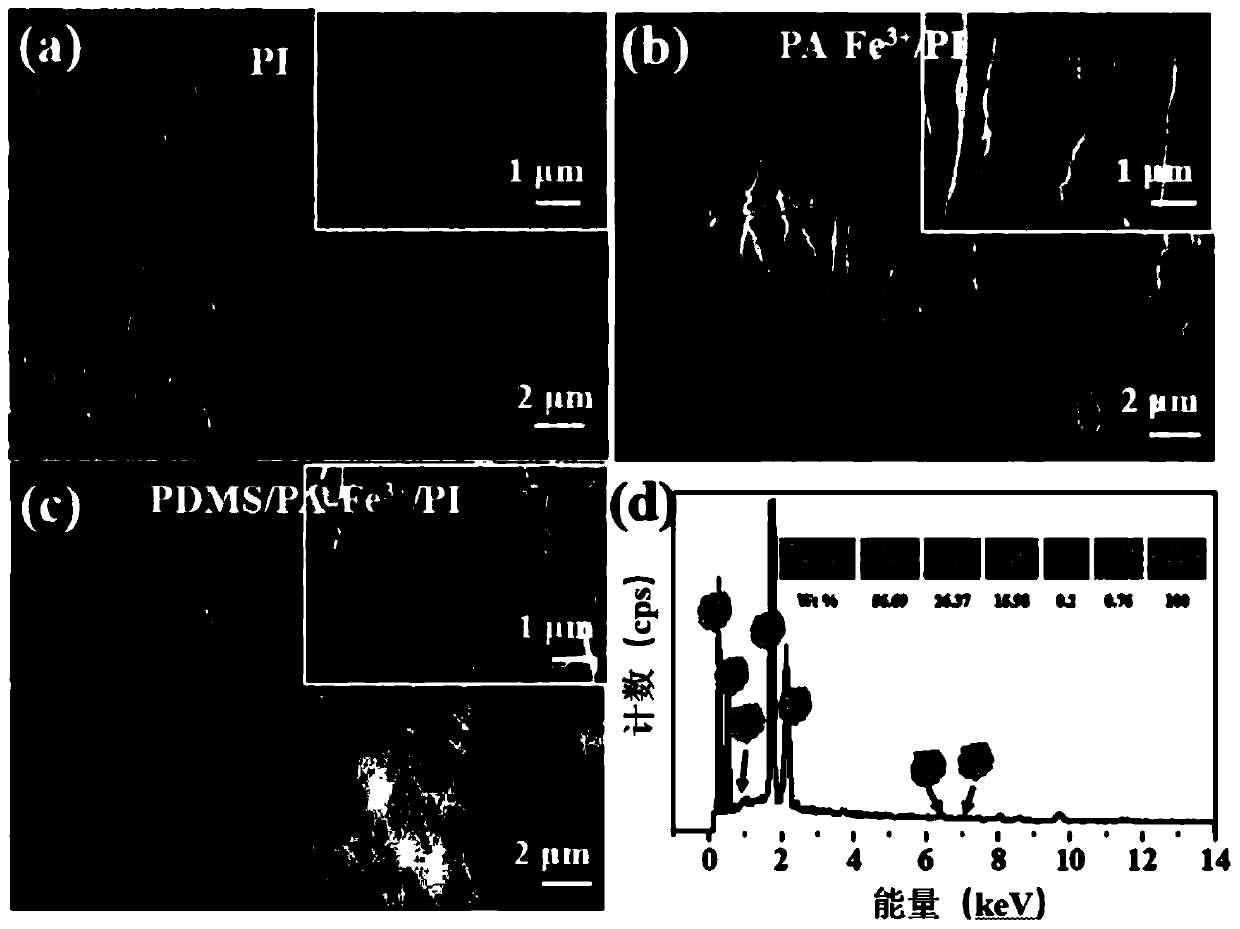

[0041] Utilize field emission scanning electron microscope (S-4800, Japan Hitachi electronics company), observe the PI film that embodiment 2 prepares, PA-Fe 3+ / PI film, PDMS / PA-Fe 3+ / PI membrane surface morphology, it can be clearly seen that the three-dimensional porous structure on the fiber is combined with the micro / nanoscale protrusions to form a double rough structure very similar to the lotus leaf surface. The field emission scanning electron microscope used this time has the function of analyzing elements, and the elements on the surface of the membrane are confirmed through the equipped EDS analysis, which confirms the successful modification of the membrane, such as figure 2 shown.

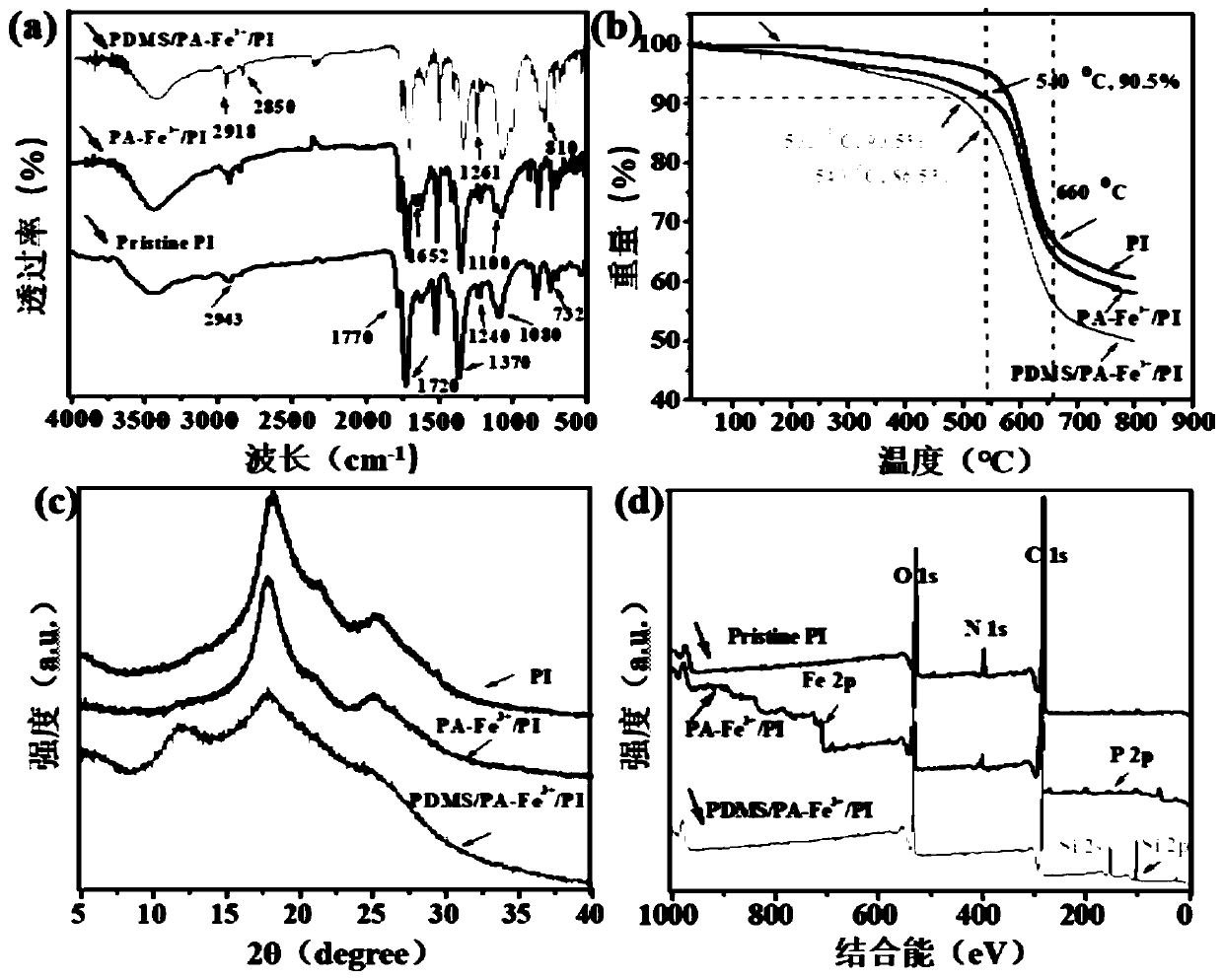

[0042] Adopt Nicolet 360FT-IR spectrometer to identify respectively the PI film that embodiment 2 prepares, PA-Fe 3+ / PI film, PDMS / PA-Fe 3+ / PI membrane functional groups and membrane structural properties such as image 3 as shown in a. One of the adsorption peaks of PI fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Hydrophobic angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com