Preparation method for multifunctional self-cleaning nano fiber membrane used for oil-water separation

A nanofiber membrane, oil-water separation membrane technology, applied in fiber type, fiber treatment, semi-permeable membrane separation, etc., can solve the problems of poor mechanical properties of fiber membranes, limit practical applications, lose superhydrophobic properties, etc., and achieve high mechanical strength , Improve the effect of oil-water separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

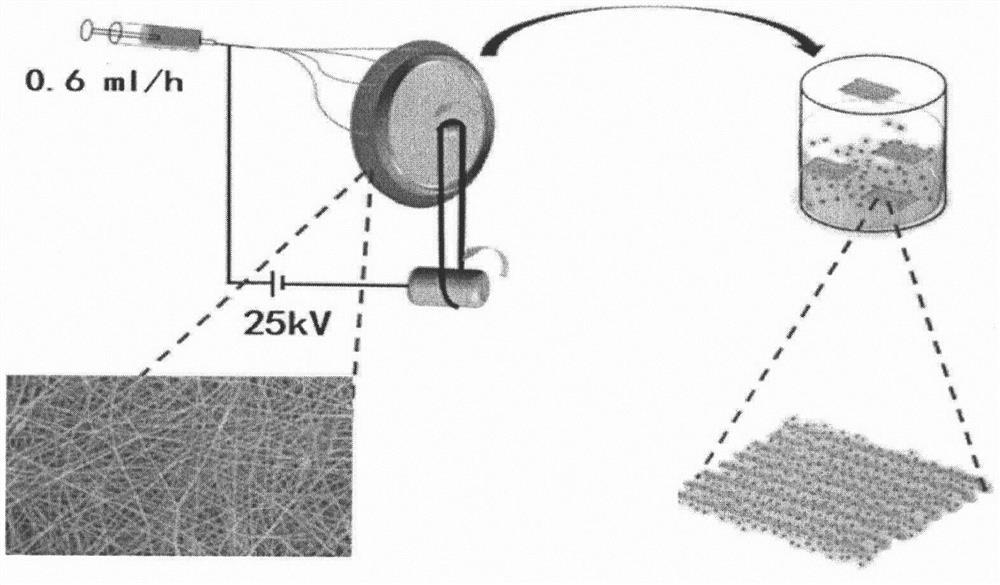

[0031] Add BPDA and PDA to a 100mL three-necked round bottom flask equipped with a mechanical stirrer, a thermometer, and an N2 inlet and outlet tube, and mix well. The mixture was stirred at minus 5 degrees Celsius for 24 h. At the end of the reaction, a viscous yellow PAA solution was obtained. The resulting product was redissolved in DMAc at room temperature to prepare an electrospinning solution. The applied voltage and flow rate are 25kv and 0.6Ml / h to provide a good electrospinning environment. The nanofibers were directly electrospun onto a horizontally rotating flywheel with a collection distance of 15 cm between the needle tip and the receiver. To obtain the final nanofibrous membrane, the PAA membrane was calcined in a high-temperature tube furnace.

Embodiment 2

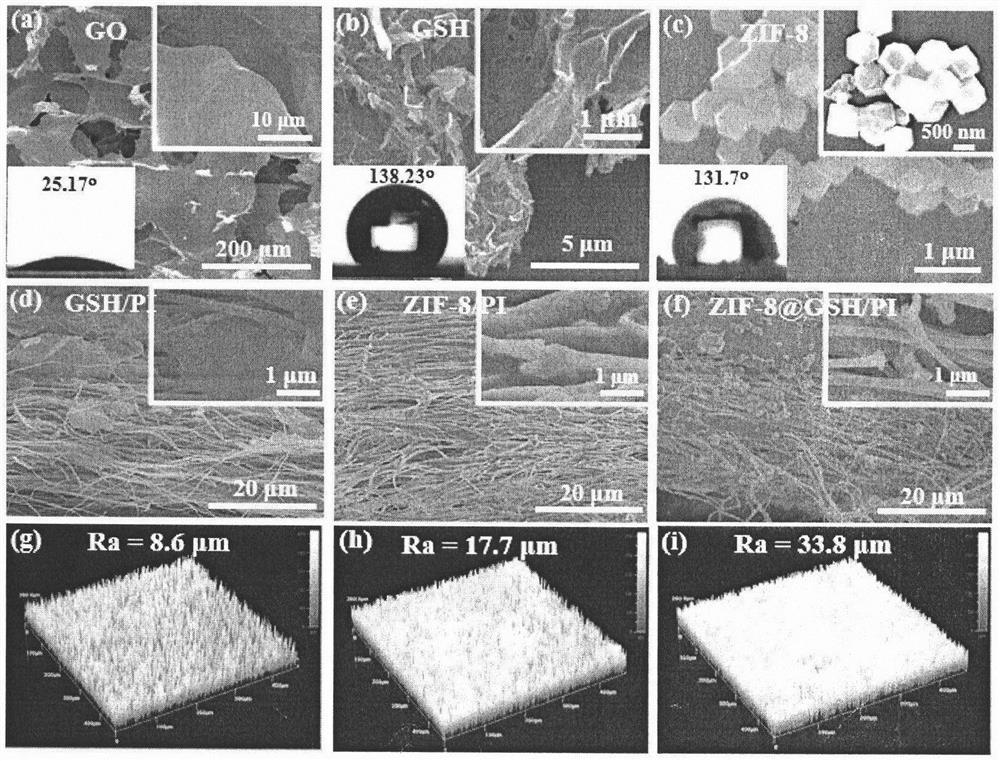

[0033] Using a field emission scanning electron microscope (S-4800, Japan Hitachi Electronics Co.), observe the surface morphology of the PI film, GSH / PI film, ZIF-8 / PI film and ZIF-8@GSH / PI film prepared in Example 2 , confirming that the membrane material prepared by the present invention has a nano-rough structure. This time, the optical image profilometry method can be used to visually see the surface structure of the composite film.

[0034] Using a contact angle measuring instrument (JC2000D1), Shanghai Zhongchen Company, China, the wettability of the surface of the nanocomposite fiber membrane soaked in different concentrations of GSH solution and ZIF-8 was tested. Lay the membrane on the test platform, aim the camera at the platform to ensure that the complete picture can be captured, fill the injection needle with deionized water, push out 2 microliters of deionized water each time, so that the droplets stay on the surface of the membrane, Using the principle of "thr...

Embodiment 3

[0038] The field emission scanning electron microscope used this time has the function of analyzing elements, and the elements on the surface of the membrane are confirmed through the equipped EDS analysis, which confirms the successful modification of the membrane, such as image 3 shown. The appearance of D and G bands in the GSH / PI and ZIF-8@GSH / PI curves confirmed the existence of a well-coated GSH layer. Furthermore, the ID / IG value increased from 0.61 to 1.11 after sulfation, which was due to the decrease in the average size of the sp2 domains after sulfation of graphene oxide. Graphene oxide is composed of highly oxidized few-layer graphene sheets with multiple surface functional groups such as hydroxyl, epoxy, and carbonyl groups. During the sulfation process, graphene oxide was reduced and brominated by hydrobromic acid, and then further hydrolyzed by thiourea and sodium hydroxide to obtain sulfated graphene. The oxygen content of GSH (11.06%) is lower than that of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com