Bisphenols monomer with imide structure and its synthesis

A technology containing imides and monomers, applied in the field of polymer chemistry, can solve the problems of polyamic acid solution instability and water vapor sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

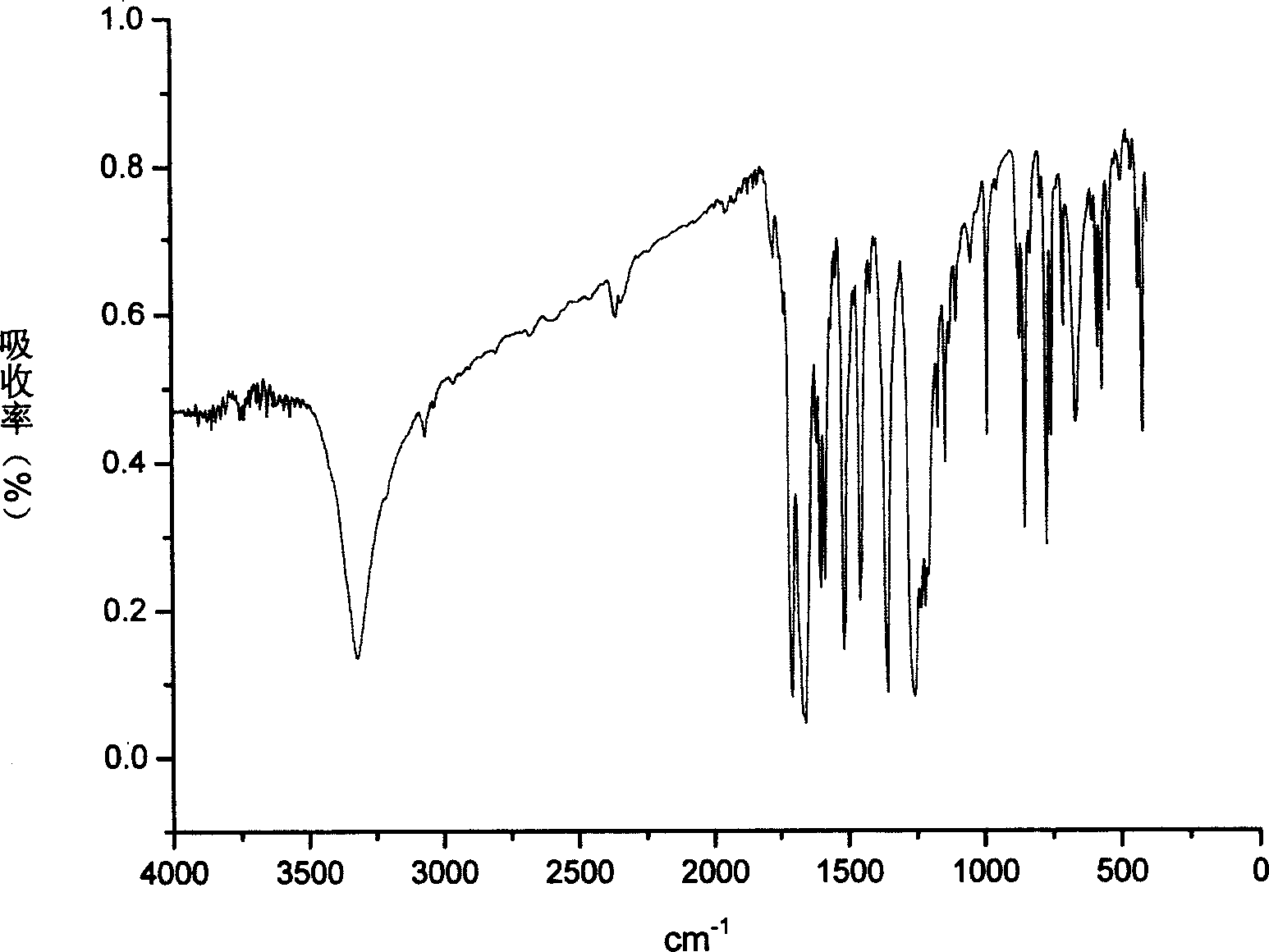

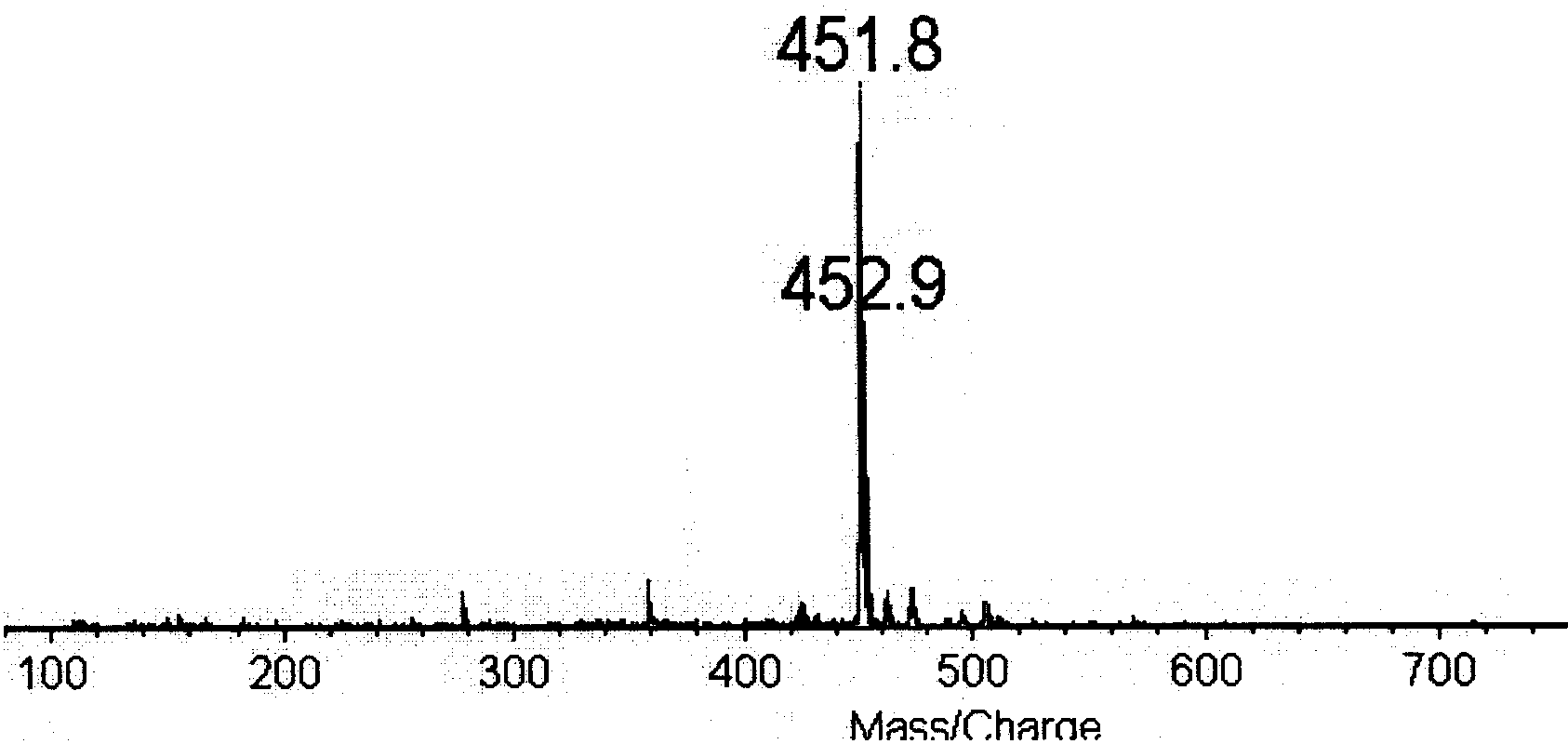

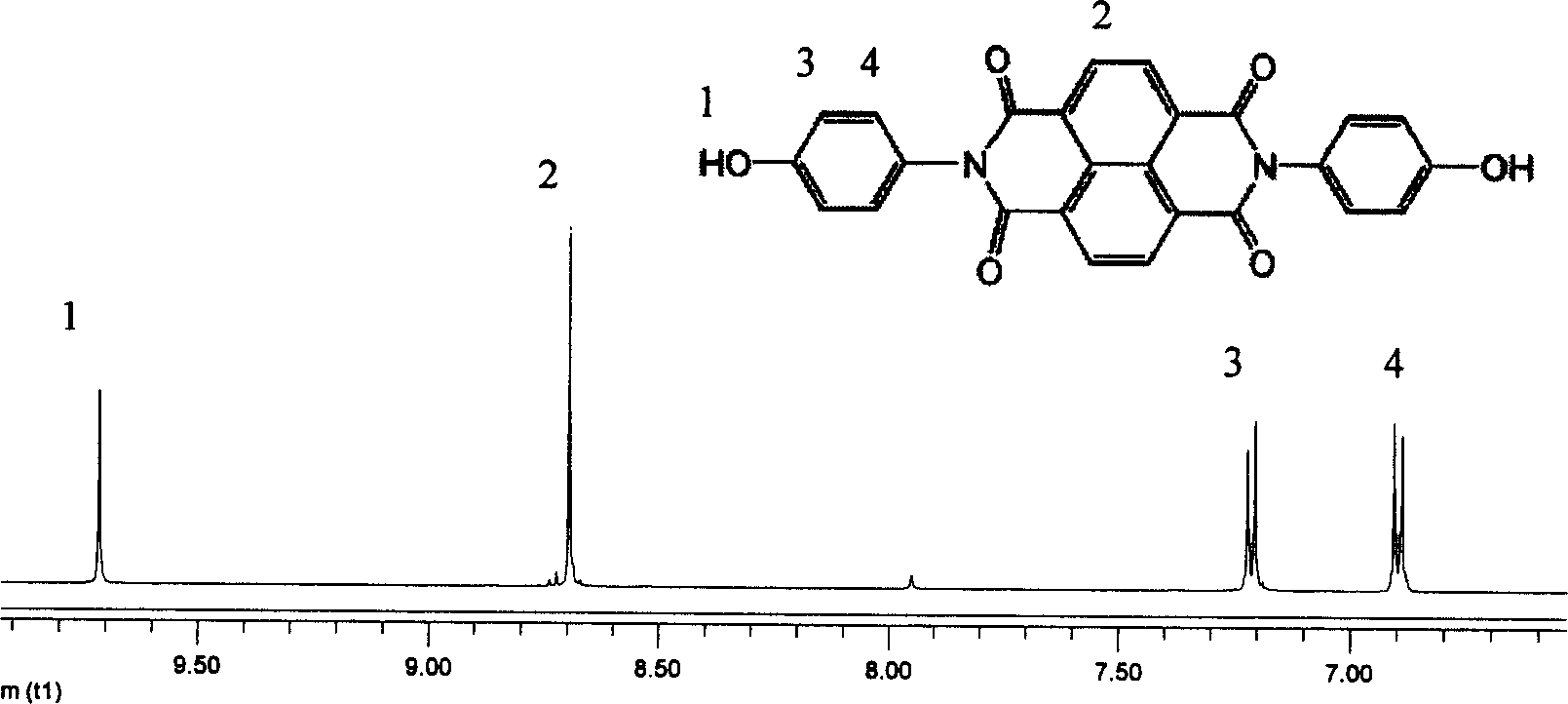

[0026] Add 200mlDMF to the there-necked flask equipped with mechanical stirring, thermometer and reflux condenser, put 21.8g (0.1mol) pyromellitic dianhydride (a) and 21.8g (0.2mol) p-aminophenol into it, at room temperature Stir vigorously for 2 hours, when the system becomes a clear solution, add toluene as a water-carrying agent, continue heating and stirring under the protection of nitrogen, and reflux with water at 110°C-120°C for 3 to 4 hours, the clear solution becomes a suspension Liquid, distill toluene at 140°C-150°C and continue to reflux at this temperature, cool down and discharge the material after 4 to 5 hours, wash with ethanol three times to remove the organic solvent in the mixed system, then boil and wash with water for 3 to 4 times, After suction filtration with a Buchner funnel, the solid product was dried in an oven at 80°C-100°C to obtain a light yellow powdery solid (38g, yield 87%), which was pure isophthalic imide bisphenol mono body.

Embodiment 2

[0028] Add 200ml NMP to the three-necked flask equipped with mechanical stirring, thermometer and reflux condenser, put 21.8g (0.1mol) pyromellitic dianhydride (a) and 21.8g (0.2mol) p-aminophenol into it, at room temperature Stir vigorously for 2 hours, when the system becomes a clear solution, add toluene as a water-carrying agent, continue heating and stirring under the protection of nitrogen, and reflux with water at 110°C-120°C for 3 to 4 hours, the clear solution becomes a suspension Liquid, distill toluene at 140°C-150°C and continue to reflux at this temperature, cool down and discharge the material after 4 to 5 hours, wash with ethanol three times to remove the organic solvent in the mixed system, then boil and wash with water for 3 to 4 times, After suction filtration with a Buchner funnel, the solid product was dried in an oven at 80°C-100°C, and the obtained light yellow powdery solid (33g, yield rate 77%) was pure isophthalic imide bisphenol monomer.

[0029] 2. ...

Embodiment 3

[0031] Add 205mlDMF in the there-necked flask equipped with mechanical stirring, thermometer and reflux condenser, mix 26.8g (0.1mol) naphthalene-1,4,5,8-dianhydride (b) with 21.8g (0.2mol) p-aminophenol Put it into it and stir vigorously at room temperature for 2 hours. When the system becomes a clear solution, add toluene as a water-carrying agent, continue heating and stirring under the protection of nitrogen, and reflux with water at 110°C-120°C for 3 to 4 hours. The clarified solution becomes a suspension, steam the toluene at 140°C-150°C and continue to reflux at this temperature, cool down and discharge the material after 4 to 5 hours, wash with ethanol three times to remove the organic solvent in the mixed system, and boil with water After washing 3 to 4 times, and suction filtering with a Buchner funnel, the solid product was dried in an oven at 80°C-100°C to obtain a yellow powdery solid (44g, yield 90%) which was pure naphthalene-1,4 , 5,8-diimide bisphenol monomer....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com